Search

Search

Search

Search

12,500-psi pressure rating floatation sub used to reach setting depth in a challenging ERD well campaign

Download PDFExtended-reach drilling (ERD) well campaign

Casing buckling and torque limit constrain casing reaching TD in ERD section

Asia

Casing buckling and torque constraints are the two primary challenges encountered landing casing to bottom in extended-reach drilling (ERD) wells in a deep, shale gas exploration campaign in Asia. Halliburton used the robust, reliable, and high pressure-rated AirGlide™ floatation sub to overcome these challenges and save the operator considerable time and costs.

A major operator faced challenges during an ERD campaign. Long horizontal sections and wellbore complexity limited the expectation of reaching bottom with casing, requiring floatation tools to help the casing reach the required setting depth.

Using WellPlan® computer software (based on the actual hookload and torque values of the wiper trip), the friction factor was observed to be 0.5 in the openhole section. Considering the tight spots and cuttings buildup, the casing would experience severe buckling and the torque value would exceed the casing thread limit without a floatation tool. With an oil-based mud weight of 17.66 lbm/gal and TVD of approximately 4000 m, it was determined that a much higher-pressure rating floatation tool was necessary.

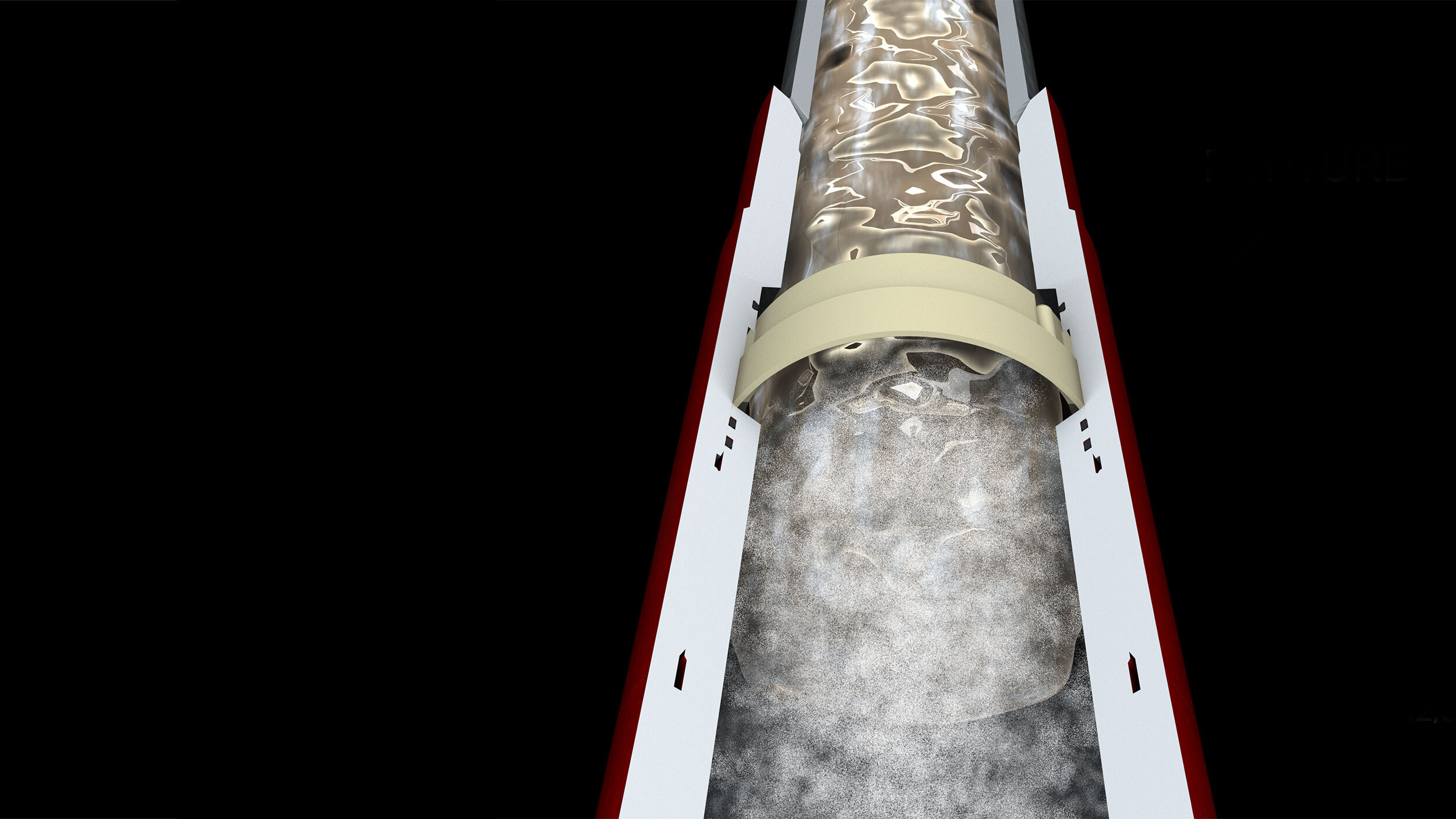

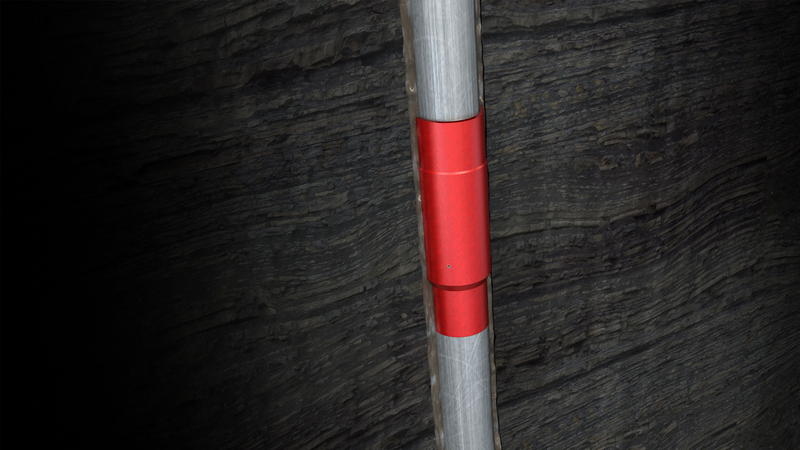

With an impressive history of successful deployment in ERD wells, Halliburton proposed using the AirGlide floatation sub with 12,500-psi actuation pressure for this campaign. An innovative glass floatation device, the AirGlide sub can significantly reduce excessive casing/formation drag by trapping air in the lower section of the casing string. This allows the casing to reach bottom faster with consistent actuation and minimal risks of plugging off due to debris.

A 5 1/2-in. AirGlide floatation sub was deployed at a depth having 66° inclination into the 8 1/2-in. open hole with a 2100-m long horizontal section. An air column length of 2200 m was designed to float the casing and ensure the torque remained within the maximum allowable value of the casing thread in case rotation was necessary at any point during the running process.

The operator selected a 12,500-psi AirGlide floatation sub to maintain the 12,000-psi hydraulic static pressure of the mud column above the floating tool.

Casing rotation equipment was also proposed as a backup to help the casing string pass through the tight spots and ledges at multiple depths, if necessary.

Despite the wellbore complexity inherent to ERD drilling campaigns, the designed setting depth was successfully achieved with no buckling and toque issues, and the tool was opened at the designed actuation pressure. The AirGlide floatation sub streamlined the casing run process and dramatically reduced the 5 1/2-in. casing run time from more than four days to only two days, saving the operator USD 240K per well. The operator plans to scale up the usage of this tool in future wells.

Days rig time saved

USD estimated savings per well

Casing buckling or torque issues

Overcome excessive drag forces to run casing to depth with the AirGlide® floatation collar.

Comprehensive well engineering tool kit for designing complex well string operations in the industry, reducing costs in the well construction lifecycle.