Search

Search

Search

Search

Optimized steerability and stability for increased drill bit efficiency

TALK TO AN EXPERTSteerability and stability are key requirements in drill bit optimization and efficiency. Halliburton Drill Bits and Services Design at the Customer Interface (DatCISM) process allows our engineers to customize gauge pad design utilizing Tracker® adjustable gauge pad technology for optimized performance. This technology optimizes bit-side cutting ability with the lateral forces applied by the BHA to change the position of the tracker element, optimizing stability and build rates.

Customized gauge pistons allow for increased steerability in directional applications and increased stability when holding angle.

01:11KARNES COUNTY, TEXAS

Minimized run hours and eliminated costs associated with additional trips reduces overall costs for the operator.

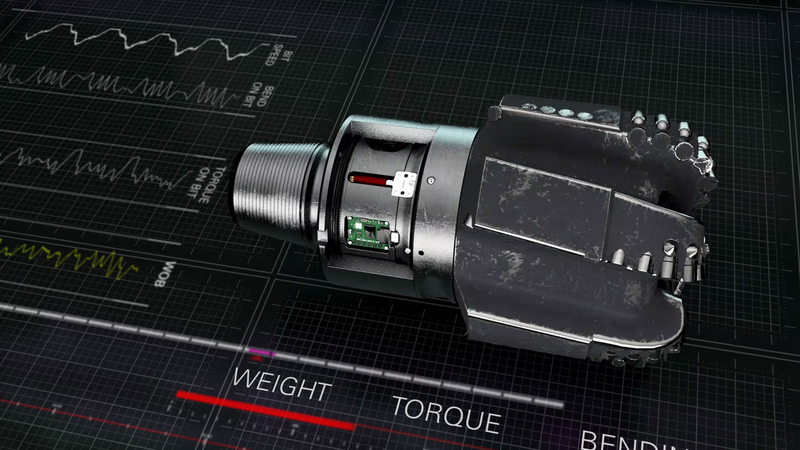

read case studyCustomized gauge pistons allow for precise movement relative to the borehole during the drilling application to optimize efficiency and performance. Throughout the development process, the Tracker gauge pad forces have been calibrated utilizing advanced Cerebro Force™ in-bit measurements allowing for optimal configurations in all applications.

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.

In-bit sensors give customers a better understanding of the downhole environment, reducing uncertainty and improving efficiency.