Search

Search

Search

Search

Safe, reliable solutions for pipe recovery and plug and abandonment

Talk to an expertHalliburton’s suite of propellant-based tools delivers precision performance for punching, cutting, and ablation, without the risks of detonation, debris, or shock loading. Engineered for plug and abandonment, pipe recovery, and intervention workflows, these tools enable efficient, single-trip operations while protecting sensitive downhole electronics.

Their reliability and performance make them an essential component in achieving successful outcomes in complex well intervention workflows.

Our propellant-based intervention tools offer a unique combination of safety, efficiency, and versatility. Their shock-free performance protects sensitive electronics and adjacent downhole tools, enabling seamless integration into complex intervention workflows.

Designed for single-trip efficiency, these tools support plug–punch–cut–log operations, reducing rig time and non-productive time (NPT). With deployment flexibility, they are compatible with e-line, tubing-conveyed systems, RF-safe igniters, and addressable electronic firing mechanisms. Additionally, each tool is classified as 1.4C, ensuring compliance with Halliburton’s HSE policies and global regulations for safe transport, storage, and handling.

Features

Benefits

Features

Benefits

Features

Benefits

The propellant tubing punch offers a safer alternative to conventional explosive or chemical punching methods. The tool uses a solid propellant and non-detonating reaction to focus combustion gases through a precision nozzle. This process ablates the tubular wall and produces clean, high-velocity perforations without shock or debris.

These tools are particularly effective in applications such as pipe recovery and well abandonment, pressure equalization and fluid circulation, and cement placement and flow path creation.

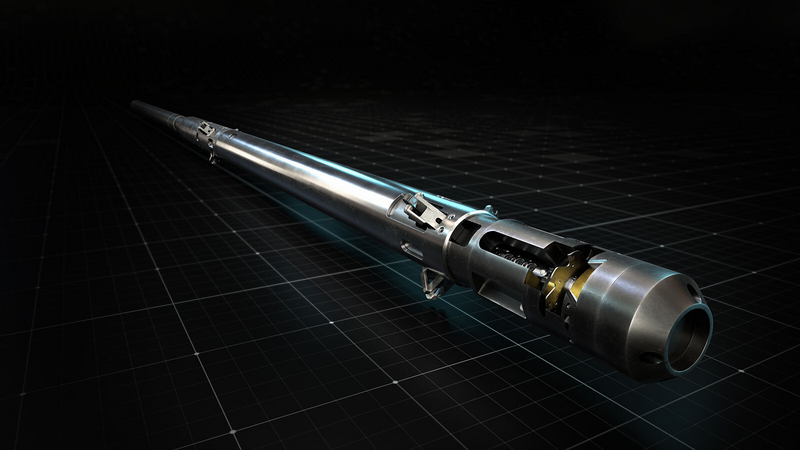

The propellant tubing cutter delivers a clean, 360° circumferential cut using a radial, solid-propellant reaction. Unlike explosive or chemical cutters, this tool minimizes debris and shock, enabling plug–punch–cut operations in a single run and reducing rig and vessel time.

Propellant tubing cutters are versatile tools used in well abandonment and P&A, tubing, casing, and drill pipe recovery, cutting plug and packer mandrels, and severing control lines and cables.

Designed to overcome wellbore restrictions, the propellant downward ablation tool uses a downward-focused, solid-propellant reaction to ablate obstructions with high-velocity energy. Its shock-free design helps ensure safe integration with sensitive electronics and other downhole technologies.

Downward ablation tools are effective in P&A, pipe recovery, intervention, and wellbore obstruction removal.

Tool |

Function |

Max target thickness |

Deployment |

Key benefit |

|---|---|---|---|---|

Tubing punch |

Perforation |

N/A |

E-line, tubing |

Multi-hole punch, shock-free |

Downward ablation |

Obstruction penetration |

7 in. |

E-line, tubing |

Slim, scalable, precise |

Tubing cutter |

Circumferential cut |

Varies |

E-line, tubing |

Clean cut, minimal debris |

ClearCut powered mechanical cutting tools perform precise, machine-shop quality, radial pipe cuts, regardless of depth and pipe compression.