Search

Search

Search

Search

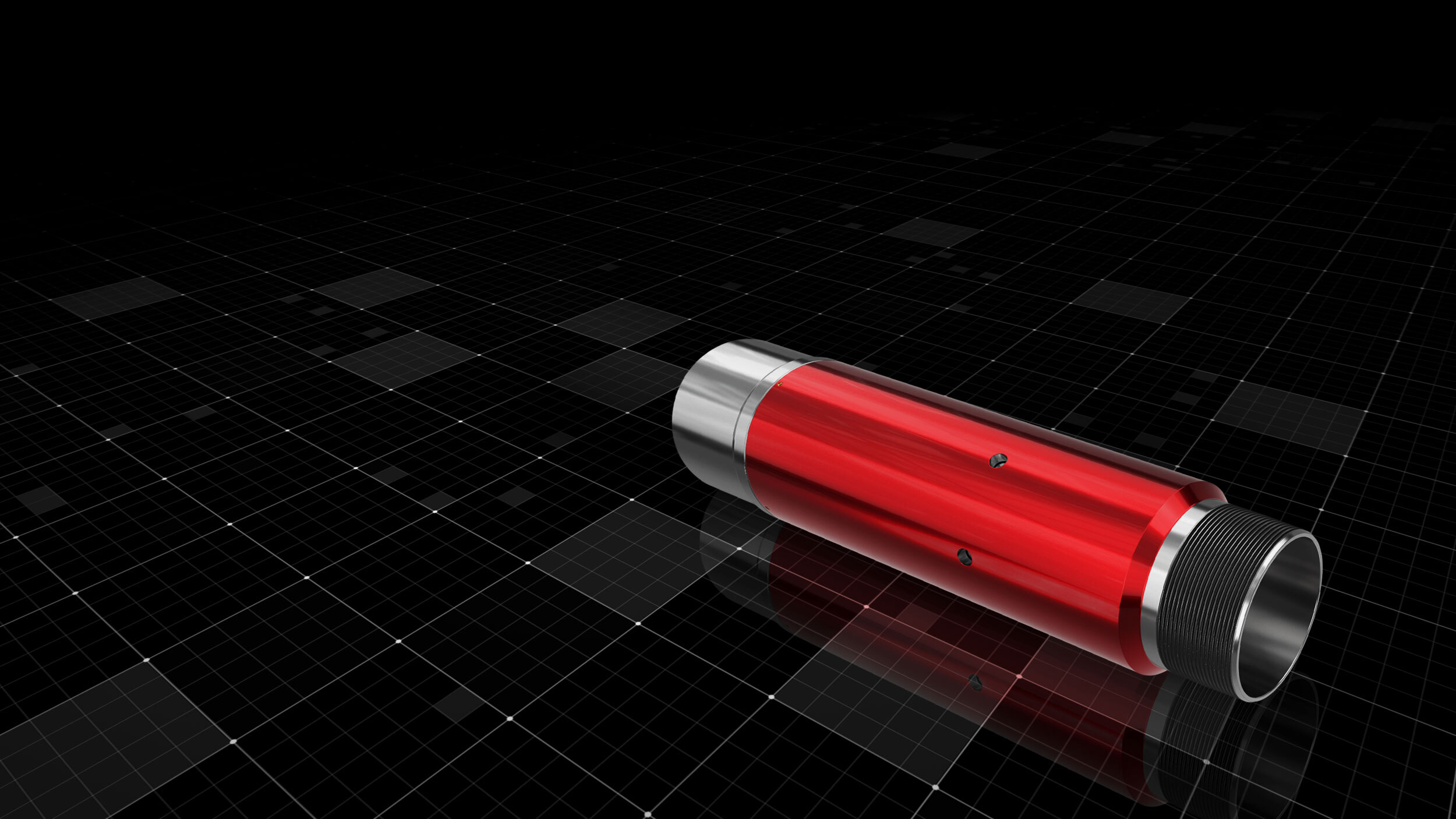

Enables multiple stage cementing operations with a damage-free drillout

Talk to an expertStage cementers typically use aluminum plugs and seat materials to open and close the tool during operation. However, aluminum can impact drill bit performance during drillout operations. The Halliburton NO-Dull™ Composite Seat Stage Cementer uses low-profile composite seat and plug materials rather than aluminum.

Just as the IADC Bit Dull Grading System uses code “NO” to record that bit cutters have no visible dulling, the NO-Dull Composite Seat Stage Cementer similarly signifies the tool enables damage-free drillout operations. The tool’s composite material design and non-rotating features help minimize drillout time and mitigate wear and tear on PDC and roller cone bits.

The NO-Dull Composite Seat Stage Cementer directly repurposes the proven, easy-to-drill composite materials from our Super Seal® II floating equipment and HWE® cementing pump down plugs. Incorporating these proven composite materials, rather than aluminum, helps prevent damage to the bit face and allows operators to drill out seats with the curve assembly and quickly move to the next section.

The inclusion of an integrated high-pressure composite baffle and float collar removes the need for an accessory baffle collar and operating plug in the well to perform casing pressure testing. This eliminates the time and costs associated with drilling out additional components in the casing string.

The NO-Dull Composite Seat Stage Cementer ports are isolated with the same seals used in Halliburton’s field-proven Fidelis™ stage cementers and MSIPC packer collars. These large sets of packer-type seal rings can withstand high-pressure differentials, eliminating potential weak points in the casing. The case of the cementer is an integral part of the casing string and externally supports the internal closing sleeve. A robust lock ring on the closing sleeve latches and locks the tool closed after completion of the second cementing stage and ensures the tool remains closed after drillout. Drillout operations are easily performed using the NO-Dull Composite Seat Stage Cementer with bent sub/motor or conventional bottom hole assemblies (BHAs) without damaging the tool’s internal sleeves and seals.

The composite material used in our tools has a proven drillability track record that has exceeded industry expectations for decades. Additional testing was performed to validate the seat strength and seal integrity of the NO-Dull Composite Seat Stage Cementer. With applications ranging from annular packer inflation to casing pressure testing, the plug and seat materials were tested up to 5,000 psi at 300°F. Extensive system-level testing confirmed that the composite seats and plugs when used together in the field, perform reliably without fear of leaking when operating the tool in the open or closed positions.