Search

Search

Search

Search

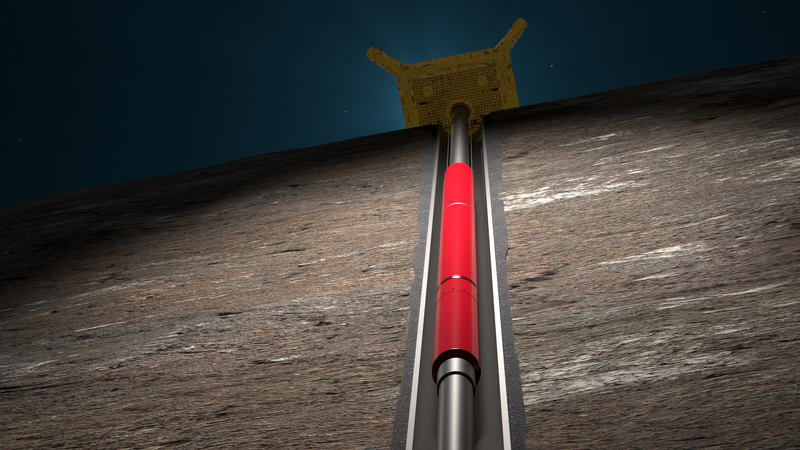

Safety valve solutions for carbon capture, utilization, and storage (CCUS)

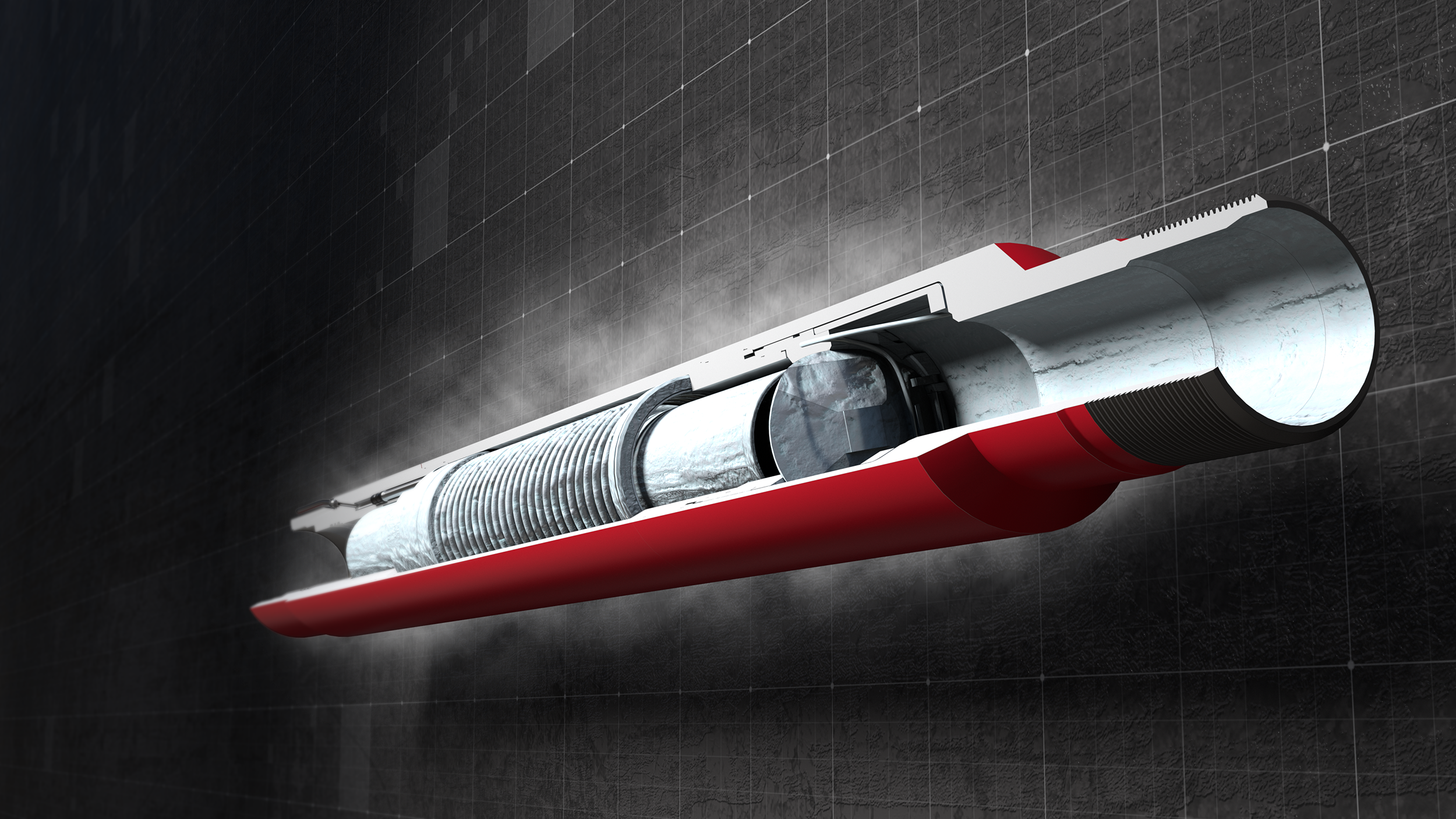

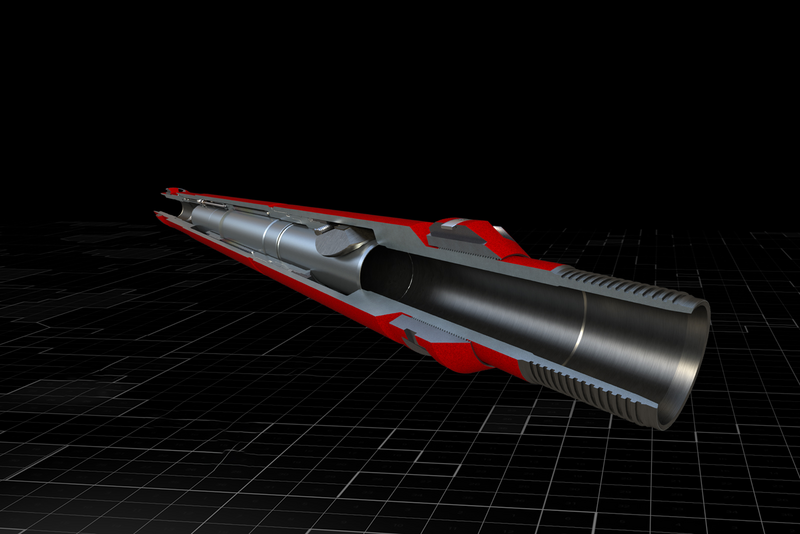

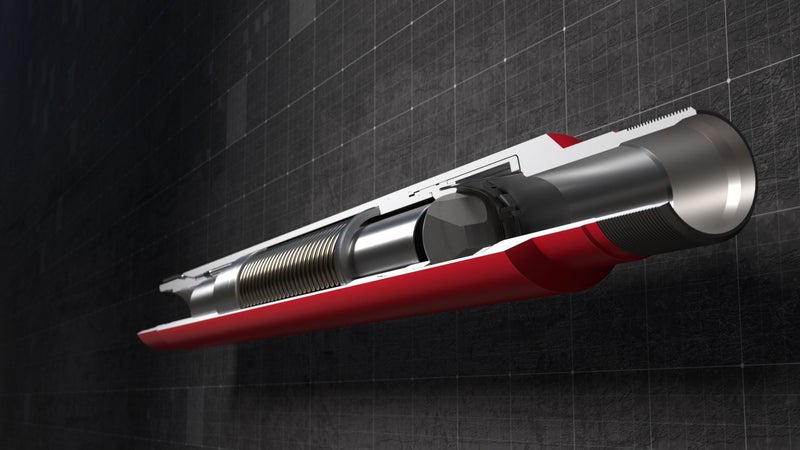

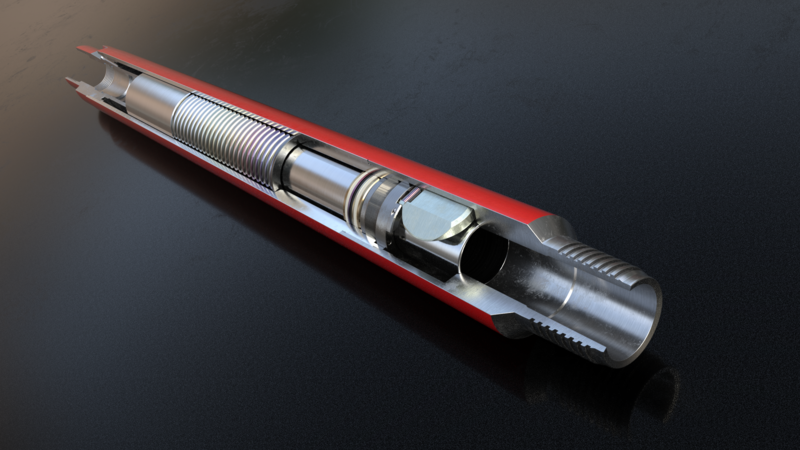

Talk to an expertThe Halliburton Neostar™ CS Tubing-Retrievable Safety Valve (TRSV) comes in four sizes to accommodate a range of completion designs. It is a single rod-piston non-elastomer flapper valve engineered for demanding environments and extended-life applications. The “CS” designation was earned by qualifying it to rigorous industry test protocols, demonstrating operability and survivability at temperatures as low as -35°C and -78.5°C respectively. NeoStar CS TRSVs are based on the field-proven SP™ safety valve design, incorporating a low-temperature rod-piston design, and metal-to-metal (MTM) sealing features within the control system to help minimize potential leak paths. These robust design features qualify NeoStar CS TRSVs as gas-tight under all operating and survival conditions, enhancing reliability in CCUS applications.

Low-temperature, non-elastomer piston seals

API validated

Non-equalizing for CCUS environments

MTM static seal at upper and lower piston positions

MTM body joints

Reliability of hydraulic actuator; dynamic and static seals verified gas-tight

Isolated control line from tubing by MTM seal with valve in closed position

Isolated hydraulic system from well pressure by MTM seal with valve in open position

Our in-house Material Science Center of Excellence, based in Singapore, conducts extensive testing of metallic and non-metallic materials in simulated CCUS environments. This research aims to inform the selection of materials that balance environmental compatibility and cost-effectiveness. The facilities are equipped to perform low-temperature tests on full-scale completion technology, reaching temperatures as low as -80°C. These tests are part of the ongoing CCUS safety valve operating life program, which addresses safety valve sizes demanded by the industry.

A safety valve capable of dynamic operation in extreme temperatures, under transient conditions, and effective sealing during survival scenarios is crucial for well integrity.

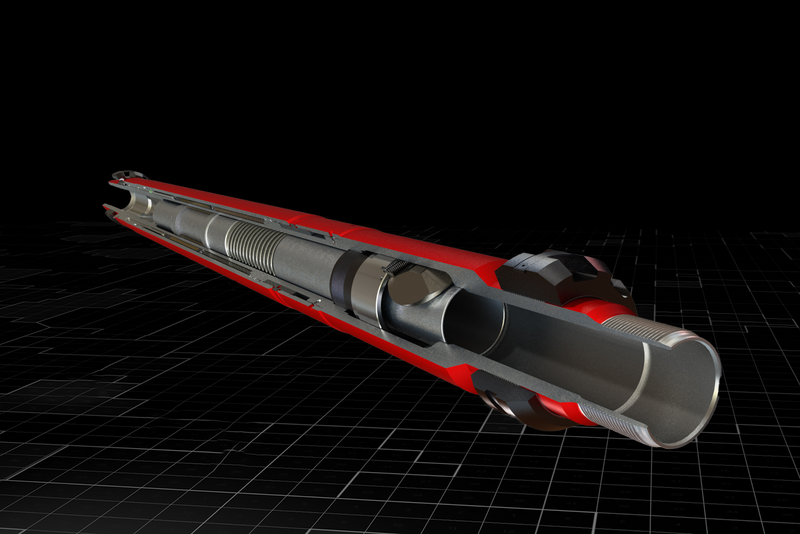

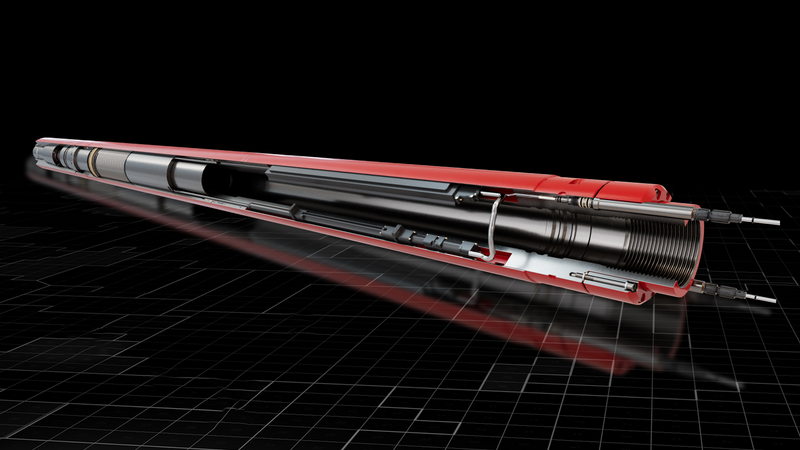

Halliburton offers a diverse range of API-qualified non-elastomeric safety valve designs in sizes demanded by the CCUS industry. These valves help provide full MTM containment in both open and closed positions. Additionally, slim OD solutions are available for permanent CCUS monitoring operations, allowing the passage of gauge, fiber-optic, and hydraulic lines. These designs can be customized for shallow or deep-set applications.

Helps to eliminate setting depth constraints, increase reliability, and reduce capex.

World’s first electric tubing-retrievable safety valve, enabling a fully electric completion system with zero risk of exposing electronics to wellbore fluid.

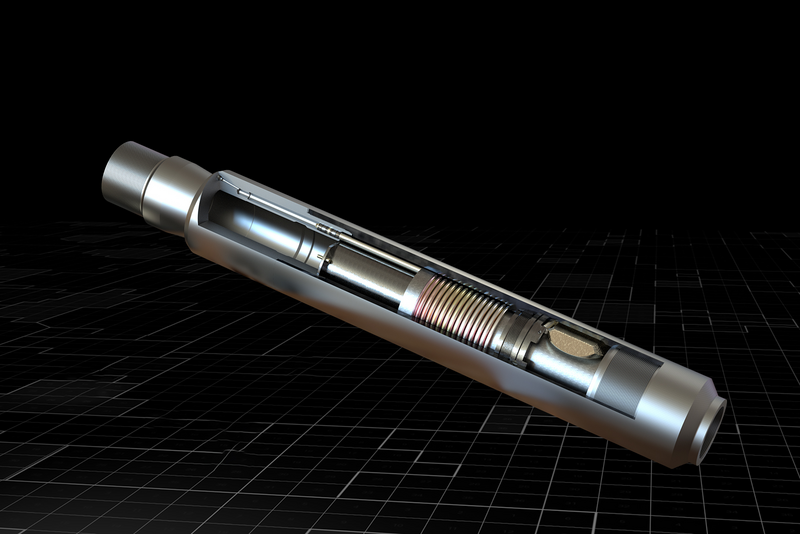

The Halliburton EquiStar® TRSV is a tubing pressure insensitive, non-equalizing, flapper-type safety valve that shuts down a well at a point below the surface.

The NeoStar TRSV is a single-rod-piston, non-elastomer flapper valve for hostile environments and extended-life applications where reliability is needed.

A single rod-piston non-elastomer flapper valve designed for general production with enhanced reliability and long life.

WellStar is a general production, hydraulically operated, downhole TRSV designed to enhances the valve’s overall reliability and provide trouble-free operation.

Halliburton tubing-retrievable and wireline-retrievable subsurface safety valves are a field-proven solution for operators.

Halliburton’s Low Carbon Solutions and low carbon technologies are enabling a balanced energy transition for a sustainable future.