Search

Search

Search

Search

Advanced PDC technology for optimized drilling performance

Talk to an expertDrilling operators face complex geological challenges, such as hard rock and abrasive formations that demand advanced cutter technologies. Halliburton's Juggernaut X PDC cutters increase rate of penetration (ROP) and reduce well construction time. They offer superior durability and efficiency. Juggernaut X PDC cutters enable operators to achieve greater footage with a single drill bit in complex drilling environments.

The development of Juggernaut X cutters began in the lab, where dull conditions were analyzed with our OculusTM automated dull grading. This process led to new cutters that outperform existing capabilities.

Superior durability and performance

Juggernaut X cutters deliver a 20% improvement in dull conditions with superior durability and efficiency. Field tests demonstrate reduced breakage, chipping, and spalling.

| Standard cutters | Juggernaut cutters | Juggernaut X cutters | |

|---|---|---|---|

| Durability | Low | Medium | High |

| Abrasion resistance | Low | Medium | High |

| Thermal stability | Medium | Medium | High |

| Shapeability | Minimal | Most | All |

| Diamond thickness | 2 mm | 3 mm+ | 3.5 mm+ |

| Advanced carbide | No | No | Yes |

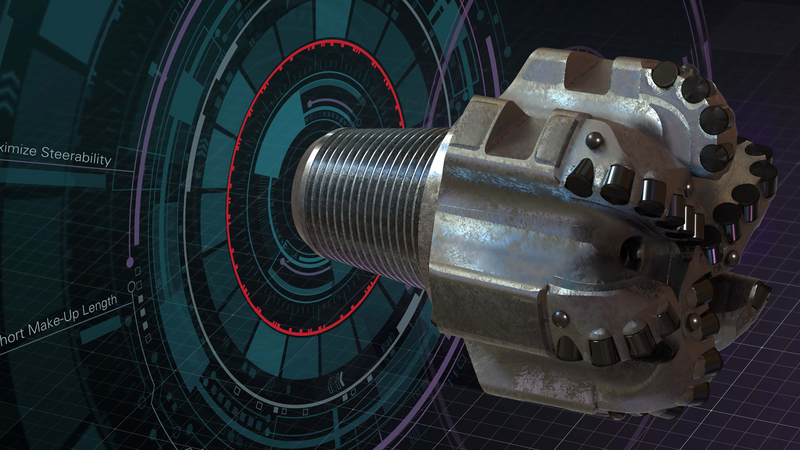

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.

Directional drill bits designed for high build rates in curve and lateral applications.

Oculus™ is the first of its kind automated dull grading system that is fully integrated into the solution creation process.