Search

Search

Search

Search

Automation-enabled platform designed specifically for longer well applications in harsh environments

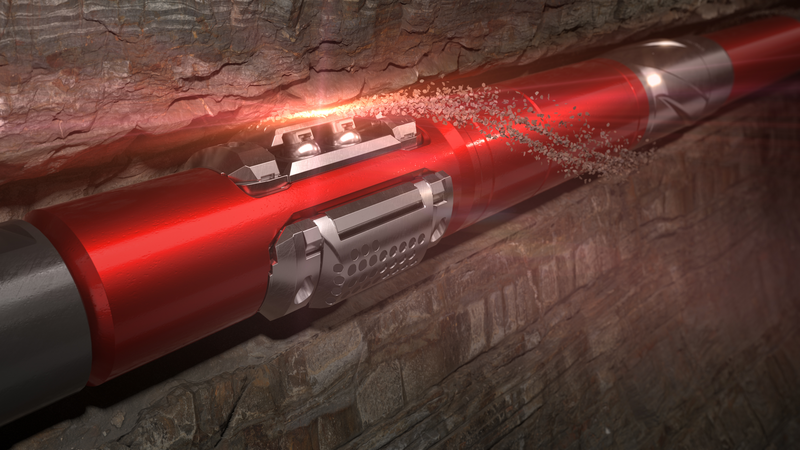

Talk to an expertThe iCruise® CX intelligent rotary steerable system (RSS) from Halliburton is a compact automation-enabled platform designed to connect with any measurement-while-drilling (MWD) system to precisely place wellbores. The system is built around the proven robust mechanical design of the iCruise® X intelligent RSS and designed to accurately place wellbores in challenging environments to enhance reliability and reduce well time.

Through the LOGIX™ automation and remote operations platform, the iCruise CX service autonomously steers wells and is equipped with real-time collision avoidance capabilities to reduce the threat of downhole hazards and provide operators with faster, consistent, and repeatable drilling performance.

High-speed processors

More compact design

Measurements per second

Rotations per minute

Innovative enhancements of the iCruise CX intelligent RSS help operators achieve predictable, reliable results in the most challenging conditions, including highly abrasive formations, variable quality mud chemistry, and high dogleg severity (DLS) applications. The RSS incorporates a new steering head with a collar designed to withstand high-frequency torsional oscillations and high make-up torque connections.

An advanced metal-to-metal sealing system delivers long-lasting durability in abrasive formations and extended reach or multilateral wells. The new seals withstand higher internal pressures and deliver more pad force at the same pressure enabling vertical-curve-lateral (VCL) sections to be drilled with stiffer bottom hole assemblies (BHAs).

Advanced seals deliver long-lasting durability in normal or abrasive formations and in normal, extended reach, and multilateral wells.

New seals withstand higher internal pressures and deliver more force enabling drilling in one run with stiffer bottom hole assemblies.

Drill smoother laterals with less human intervention with automation enabled by the CruiseControl technology.

The iCruise CX features a 52% more compact design and multiple connect-ability capabilities. The shorter design optimizes stabilizer placement for predictable dogleg output. The electromagnetic (EM) short-hop communication system utilized by the iCruise® CX allows connectivity from the RSS to any MWD system.

The system includes the industry-leading CruiseControl® technology that provides autonomous steering capabilities, increased reservoir contact, and reduced well time. The iCruise CX intelligent RSS takes near-bit inclination and azimuth measurements 1,000 times per second allowing precise system control and minimized wellbore tortuosity. The automation capabilities in the system contribute to maximizing asset value for customers through reduced well time and lower costs per BOE, while delivering predictable, dependable, and consistent results.

Steering commands help plan and project the well path, optimize wellbore trajectory, and avoid hazards and collisions.

Vibration commands provide optimal drilling parameter ranges to manage downhole vibration and allow better directional control.

Halliburton rotary steerable systems are engineered with advanced technologies to reduce well time and accurately place well in reservoir.

Expand drilling capabilities to optimize drilling performance and maximize asset value.

Increase the consistency and performance of well construction operations by integrating subsurface automation, digital twins, and remote operations