Search

Search

Search

Search

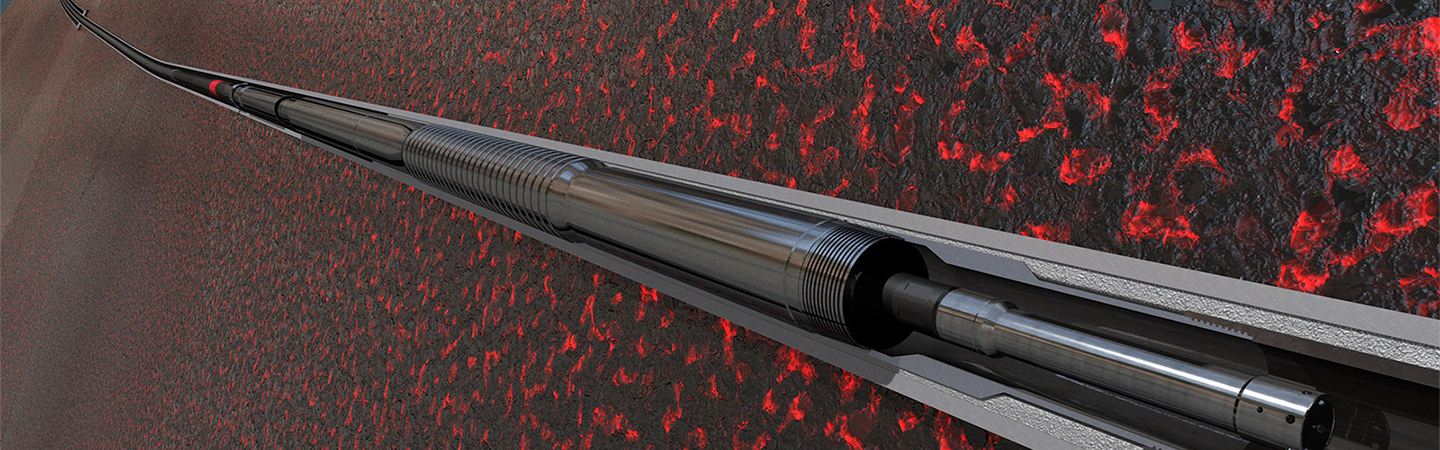

Many challenges in geothermal development can be addressed with services and technologies used in the oil and gas industry. Halliburton is a leading provider of liner hanger systems with more than 20 years of experience providing engineered liner solutions globally. Our comprehensive portfolio of liner hanger equipment and cementing services is designed to operate at ultra-high temperatures of up to 650°F (343°C), helping you efficiently develop resources and achieve the lowest cost per megawatt in geothermal well construction.

Halliburton offers tiered solutions based on your specific well construction requirements. Whether designing a liner job requiring a liner-top seal, hanging a liner off-bottom or placing a liner on-bottom, Halliburton can assist you every step of the way.

Designing a liner installation that requires a liner-top seal (well barrier) is a very complex operation. The Geothermal Expandable Liner Hanger provides a 360° metal-to-metal seal and high-load bi-directional anchoring capabilities, without requiring cement on top of the liner. The latest innovations in liner hanger technology are built into the system, enhancing the overall operation. Additional tieback capabilities in latched and unlatched (cemented or non-cemented) designs are available.

Designing a liner installation that requires liner support once set and cementing a liner on depth is a challenging application. The MatchSet Mechanical Liner Hanger provides a superior load-bearing liner anchor mated with a robust tool system to allow for cementing operations. Additional tieback capability in an unlatched (cemented or non-cemented) design is available.

Designing a liner installation that requires liner drop-off and cementing liner on bottom is a straightforward procedure. The MatchSet Drop-Off System provides a latching profile mated with a mechanical-release tool system to allow for cementing operations. Additional tieback capability in an unlatched (cemented or non-cemented) design is available.