Search

Search

Search

Search

Eliminate umbilicals and hydraulics to help improve safety, cut rig time, and deliver wireless subsea control

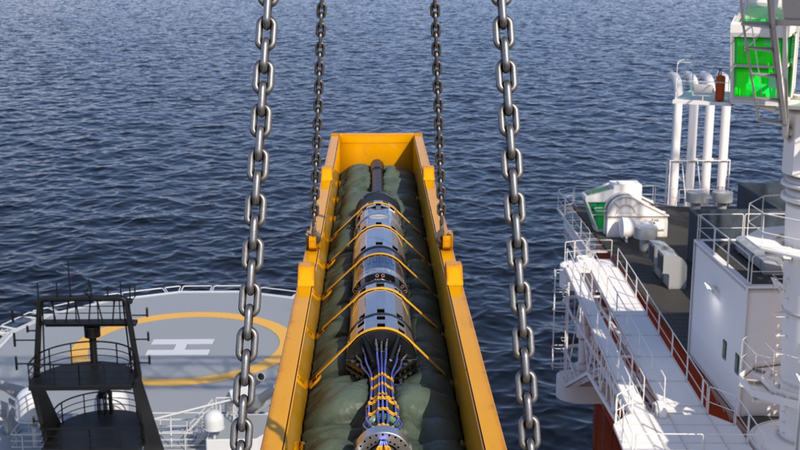

talk to an expertThe enhanced remote operated completion system (eROCS) removes traditional umbilicals and hydraulic power units (HPUs) to help reduce rig time, minimize red zone exposure, and optimize offshore efficiency. Built on field-proven technology, the system provides wireless control, advanced monitoring, and unmatched versatility for both live and dead wells.

Core advantages for subsea efficiency:

Traditional systems rely on large topside spreads and HPUs. These components increase rig-up time, require significant deck space, and expose personnel to high-pressure zones. eROCS removes these to help free valuable topside footprint and reduce operational risk. Operators remove umbilicals and HPUs to simplify mobilization, cut costs, and improve crew safety during completion and intervention campaigns.

Operate tubing hanger running tools (THRT), test trees, and downhole functions remotely with high-speed wireless communication (typically under one second response time).

Advanced valve packs combine pressure regulation and leakage detection in a single unit, supported by integrated flow and temperature sensors for real-time diagnostics.

The short length fits below blowout preventer (BOP) pipe rams, reducing rig-up complexity and improving flexibility. Modular design adapts to customer-specific requirements.

Fully redundant batteries with subsea trickle charging and multiple wired or wireless communication options help ensure operational continuity.

Operators face increased pressure to simplify subsea completions, reduce crew exposure, and accelerate complex campaigns. This completion system simplifies deepwater operations, reduces personnel in live well environments, and optimizes rig time for complex projects. The system also integrates with advanced orientation technologies such as the Optime tubing hanger orientation system (OTHOS) to achieve accurate alignment without additional hardware.

Relevant standards (where applicable), design based on:

API STD 17G, API STD 17F, ISO 13628-7, ISO 13628-6, NORSOK R-002

| Operating limits | Design and manufacturing specifications |

|---|---|

| Inspection method | Non-intrusive pressure pulse analysis (no inline tool required) |

| Max operating pressure | 15.000 psi / 1035 bar |

| Maximum working pressure (external) | 10.000 psi / 690 bar |

| Maximum pressure function lines | 12.500 psi / 862 bar |

| Service temperature | 23–140°F / -5–60°C |

| Hydraulic functions | 21 + 2x pass through lines for chemical injection |

| Electrical feedthrough | 3 (various termination options) |

| Battery capacity | ~14 days (excluding backup) |

| Subsea trickle charging | Yes |

| Operating limits | Design and manufacturing specifications |

|---|---|

| Approx weight (incl. control fluid) | 4000-5000 lbs / 1800-2300 kg |

| Approx Overall Length, (eROCS flange-to-flange) | 67-86” / 1700-2200 mm (depending on configuration) |

| Outer diameter | Max 18.62” / 473 mm |

| Inner diameter (pending configuration) | 6.375” – 6.8” / 161.9mm - 172.7 mm |

| Standard connections | 8” TPC UX-163 ultra compact flange – BOTTOM |

| Topside communication | RF based Wireless Communication (tablet with RF) |

| Subsea communication options | Wired options through EDL or Wired Drill Pipe Wireless mode through BOP, communicate to topside via ROV, ROV cage/TMS, BOP Control System or eSCILS. |

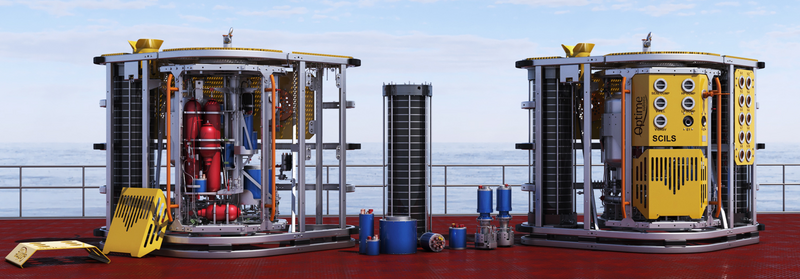

Halliburton offers innovative subsea safety systems for applications in completion and intervention operations.

Achieve faster, safer subsea completions through precise orientation. OTHOS reduces rig time, improves safety, and simplifies offshore operations.

Minimize complexity and maximize flexibility with umbilical-less subsea tubing hanger installation systems

Industry first, field-proven closed-loop subsea controls unit complete with redundant subsea pumps, control modules, and a hydraulic reservoir