Search

Search

Search

Search

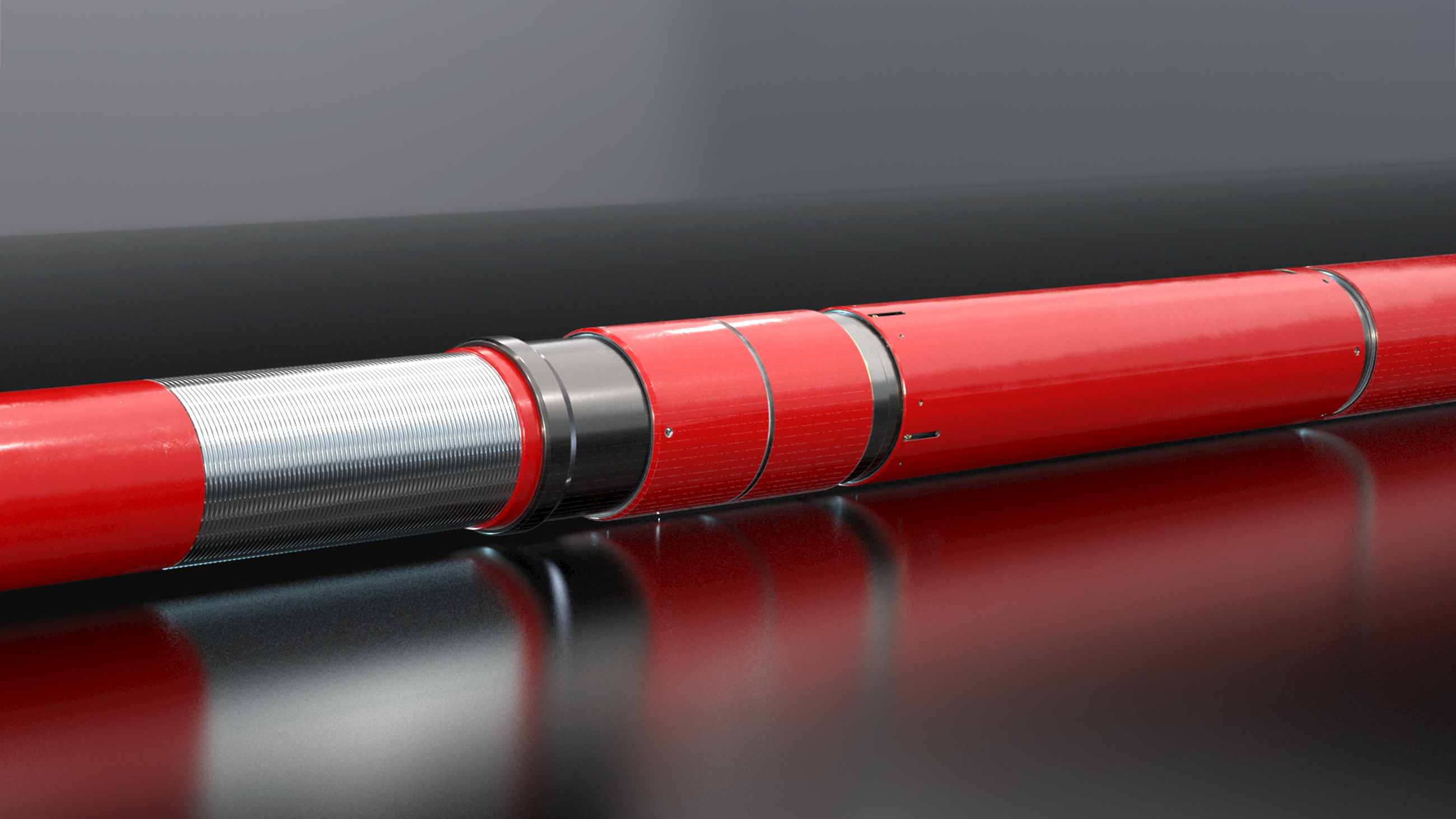

Improved oil recovery with washpipe-free ICD completions

Talk to an expertInflow control devices (ICDs) are proven valuable assets to help balance the influx profile in long horizontal wells. Whether the goal is to eliminate the heel-toe effect or mitigate high-permeability variances from zone to zone, ICD completions are an effective solution to increase total oil recovery throughout the life of the well. The Halliburton EquiFlow® RICD™ remote inflow control device combines ICD and screen technology with washpipe-free capability and mechanical sliding sleeve functionality. This system helps stabilize fluid production and has the flexibility to allow selective shutoff sections of the production interval, which provides a simple and robust method to control and isolate flow and ensure reliable sand control.

ICD completions are traditionally deployed with washpipe or an inner string to accommodate effective fluid circulation, displacement, and washdown capability. The EquiFlow RICD device is paired with a hydraulically activated ICD run as a closed system to provide washpipe-free completion deployment. The EquiFlow RICD device holds internal pressure when closed and is open to full injection/production flow once it is activated and pressure is bled off. While running in hole (RIH) the completion, the valves are closed and the completion string can be pressured up internally to set packers or run any other pressure-operated tools in the completion. If using a washdown shoe or circulation subassembly in the bottomhole assembly (BHA), the well can be circulated without a washpipe inner string.