Search

Search

Search

Search

Customized solution that helps manage and mitigate corrosion effectively, ensuring optimal performance and reliability of your operations

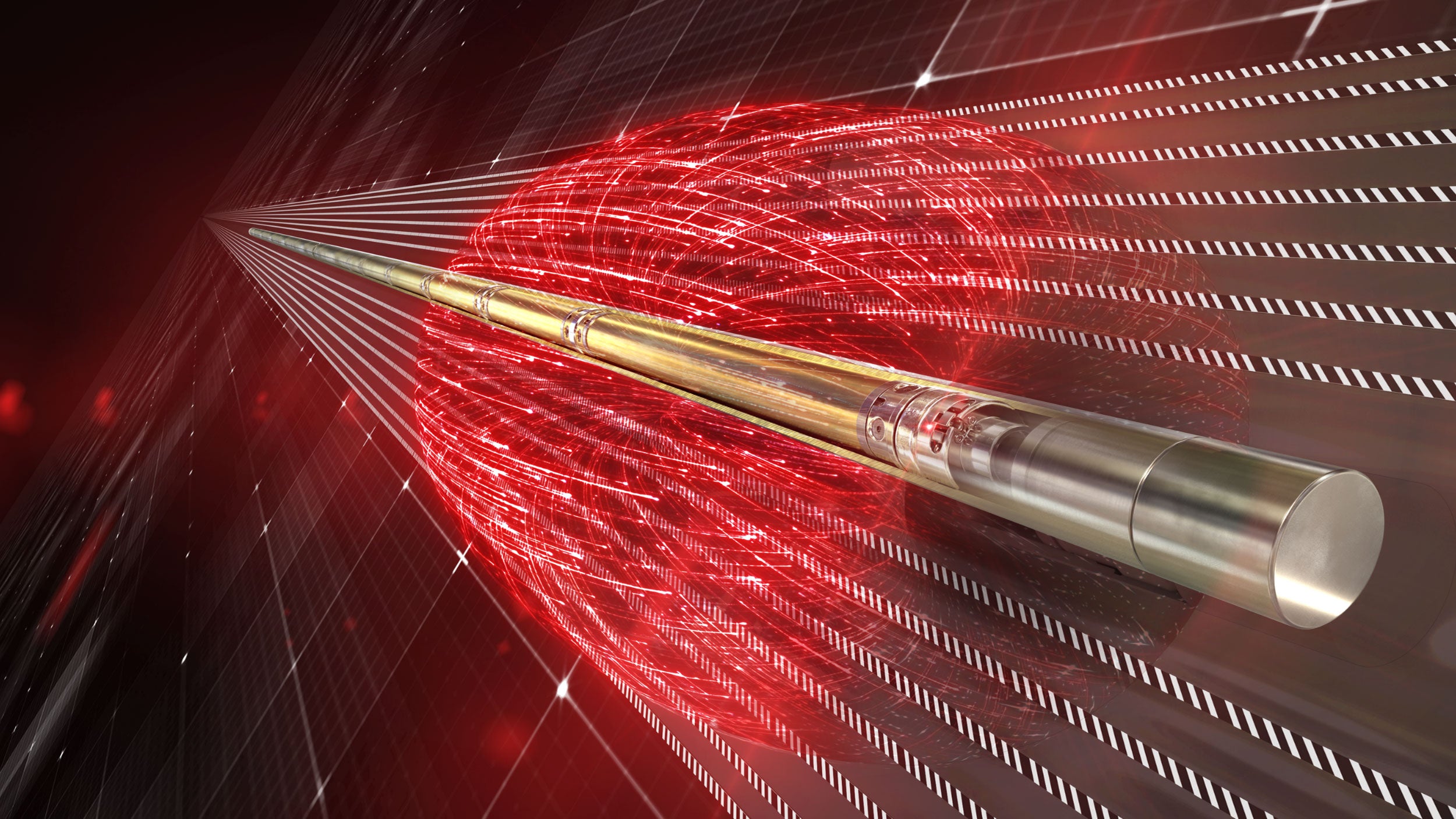

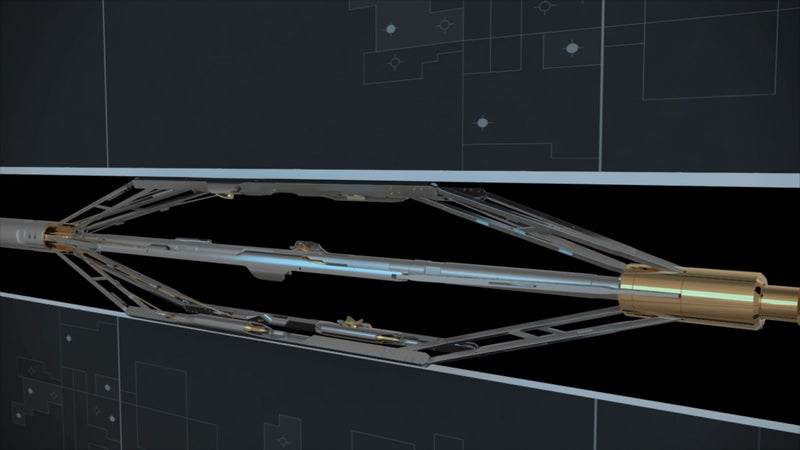

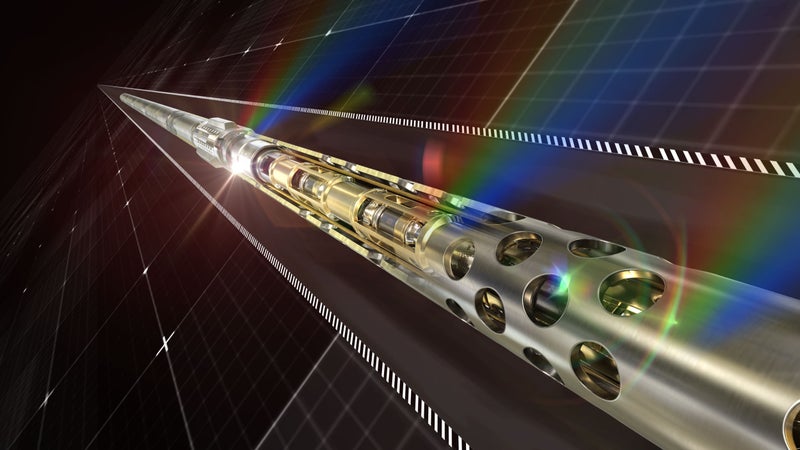

Talk to an expertUsing High-Definition Frequency (HDF) technology, the IntelliGuard™ corrosion evaluation service accurately quantifies metal loss across one to seven concentric strings of pipe in a single trip. This advanced capability allows you to quickly assess the condition of your entire well, significantly reduces diagnostic time, and provides you with detailed information for effective monitoring and timely interventions.

IntelliGuard service provides you with accurate data on the condition of your wellbore pipes, enabling you to make informed decisions and uphold the integrity of your operations. Rely on Halliburton for the advanced technology and expertise essential for achieving optimal well performance.

Maximum temperature

PSI maximum pressure

Inches maximum tool outer diameter

maximum total wall thickness

HDF technology ensures precise detection of metal loss and corrosion-induced defects. This advanced diagnostic capability provides reliable data, helping you make informed decisions to maintain the integrity of your operations.

This service operates on mono-conductor wireline or in memory mode on slickline, offering flexibility and efficiency. This versatility enhances wellsite operations, making the process smoother and more efficient.

IntelliGuard service enables rigless operations, improving conveyance flexibility and addressing various well construction and operational challenges. This feature allows for more efficient interventions without the need for a rig, saving time and costs.

Accurate production profiling information for critical well decisions.

Acoustic analysis tools that pinpoint costly wellbore leaks by analyzing sound waves that describe flow patterns in the formation and casing.

Monitor reservoirs to increase production, improve recovery, and find bypassed pay.