Search

Search

Search

Search

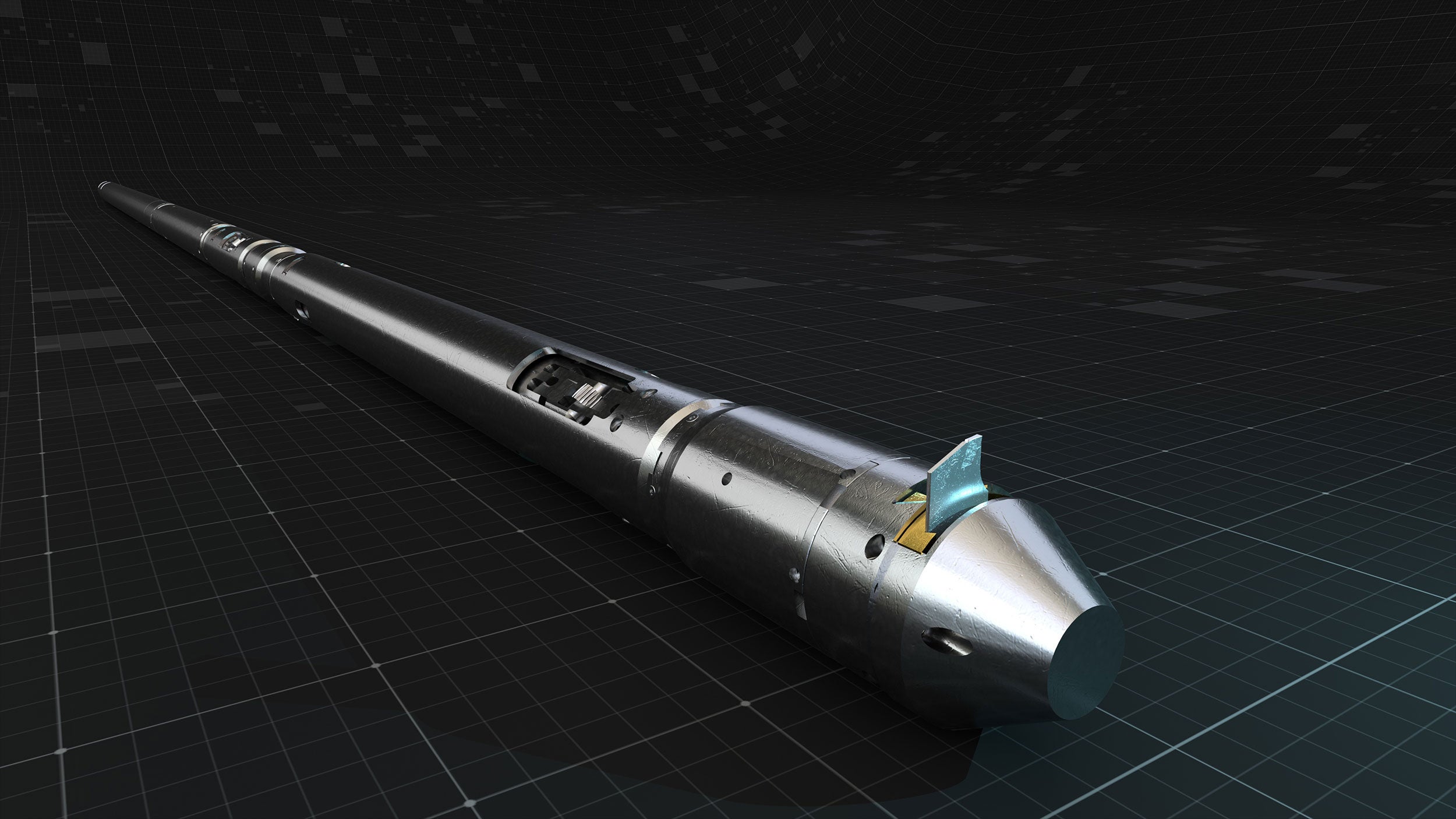

The ClearCut slim cutter is Halliburton’s electromechanical option for precision pipe cutting during well intervention

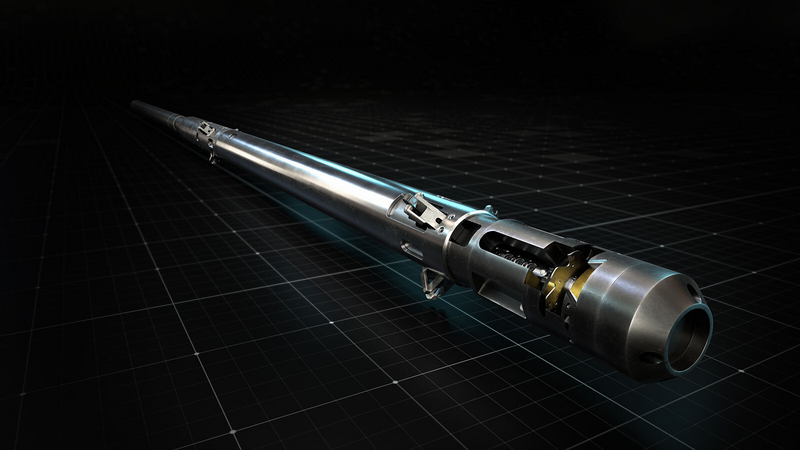

Talk to an expertThe ClearCut slim cutter is Halliburton’s electromechanical option for precision pipe cutting during well intervention. It is designed for e-line and digital slickline deployment and offers a compact profile that helps reduce operational complexity. By using a non-explosive approach, the tool supports safer handling and streamlined logistics for offshore and remote environments.

Operators can use this technology to manage plug and abandonment, recover stuck pipe, or perform routine intervention while aiming to minimize footprint, minimize HSE risks, and improve efficiency.

Explosive cutters often require additional precautions and regulatory steps. This electromechanical design uses an alkaline power pack, which helps reduce dangerous goods transportation requirements. The approach can simplify planning and reduce exposure to certain risks associated with traditional cutting methods.

The tool’s compact size allows it to pass through restricted IDs, making it suitable for 2 ⅜-in. pipe that is not typically severed with an electromechanical cutter. The cutting process can be completed in less than 15 minutes, and deployment options include digital slickline or e-line, which offers flexibility for weight-limited offshore platforms that can only support a small-footprint slickline unit. The design also supports controlled debris management.

This solution can be considered for tubing intervention applications where pipe cutting or small cut-to-release packers are planned. It is also suitable for stuck pipe scenarios to restore well access, plug and abandonment activities, and tailpipe drop-off cuts where tubular severance is required. Its compact footprint supports rigless interventions on small platforms where space and crane lift capacity may otherwise limit operations, helping improve workover economics in challenging environments.

The cutter can be deployed rigless using digital slickline for compact and efficient operations. It is also compatible with e-line units, including third-party systems, for added flexibility.

| Specification | Value |

|---|---|

| Tool outside diameter | 1.69 in. (42.9 mm) |

| Cutting range | 2 3/8 to 4 in. pipe |

| Maximum pressure | 15,000 psi (103.4 MPa) |

| Maximum temperature | 250°F (121°C) (Alkaline battery) 330°F (165°C) (e-line ops) |

| Tool length | 12.92 ft (3.94 m) |

| Tool weight | 135 lb (61.3 kg) |

| Deployment | RDSL and e-line |

Two cutting head sizes are available for different pipe ranges.

Compared to explosive, chemical, plasma, and flammable solids methods, this approach can help reduce handling risks, simplify logistics, and provide controlled cutting performance. It is intended to support safer and more predictable intervention planning.

ClearCut powered mechanical cutting tools perform precise, machine-shop quality, radial pipe cuts, regardless of depth and pipe compression.

The ClearTrac tractor service is the most advanced wireline conveyance technology on the market for highly deviated or horizontal wells.

ClearCut® SB uses the most advanced electro-mechanical cutting technology available to sever tubing, casing, drill pipe (DP) and heavy-weight drill pipe (HWDP).