Search

Search

Search

Search

Precision pipe cutting for well intervention

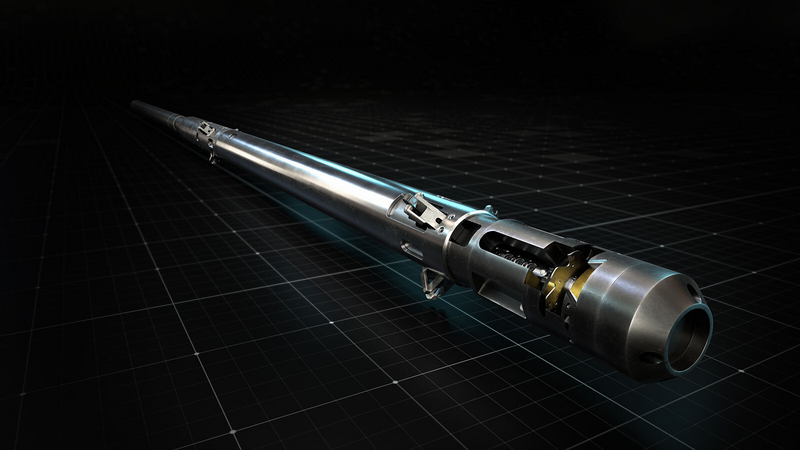

Talk to an expertThe ClearCut® SB cutter is Halliburton’s electromechanical solution for safe, efficient pipe recovery in well intervention, completions, and plug and abandonment (P&A) operations. Designed to eliminate explosive risks and reduce rig time, the cutter delivers machine-shop quality cuts across a wide range of tubulars, including drill pipe, casing, and corrosion-resistant alloys.

ClearCut SB cutter replaces traditional explosive cutters with a brushless motor and customized anchors that produce flare-free cuts without hazardous materials. This non-explosive design removes the need for escort services, streamlining logistics and lowering health, safety, and environmental (HSE) exposure. Operators deploy the cutter using mono, hepta, or coated cable, making it compatible with most e-line units and ideal for rigless interventions.

Case Study

When every second counted, Neptune Energy turned to Halliburton for a high-stakes solution in the North Sea. Discover how ClearCut™ powered mechanical cutters delivered precision, safety, and speed—resolving a critical stuck pipe incident that others couldn’t.

read case studyEngineers use ClearCut SB cutter to address stuck pipe, sidetracking, and abandonment challenges. The tool offers six head sizes and six anchoring setups, enabling cuts from 3½ to 9⅝ inches in diameter and up to 1.4 inches in thickness. It severs all API 5CT tubulars, including SM2535-125, Inconel, GRE, and VIT, without damaging adjacent casing or tubing.

The cutter operates reliably in extreme environments, up to 25,000 psi and 350°F, making it suitable for high-pressure, high-temperature wells. Adjustable cut speed minimizes debris, and surface readout displays provide real-time monitoring for precision and control.

Operators combine ClearCut SB cutter with Halliburton’s Freepoint Tool to identify stuck locations and execute targeted cuts without pulling out of hole. This integration saves rig time and reduces operational cost.

Minimum ID restriction

Tool weight

Maximum temperature

Tool outside diameter

This cutter supports multiple cuts in a single deployment, enhancing operational efficiency and reducing downtime. Whether used in coiled tubing interventions, sidetracking, or P&A jobs, the cutter delivers consistent performance and repeatable results.

ClearCut SB cutter meets the needs of well intervention specialists, completions engineers, and P&A teams. Its electromechanical design supports safe, compliant pipe recovery in offshore and onshore environments, making it a trusted tool for completions, production optimization, and decommissioning.

The ClearTrac tractor service is the most advanced wireline conveyance technology on the market for highly deviated or horizontal wells.

ClearCut powered mechanical cutting tools perform precise, machine-shop quality, radial pipe cuts, regardless of depth and pipe compression.