Search

Search

Search

Search

Reliable acoustic verification and monitoring for dual-trip intelligent completion installations

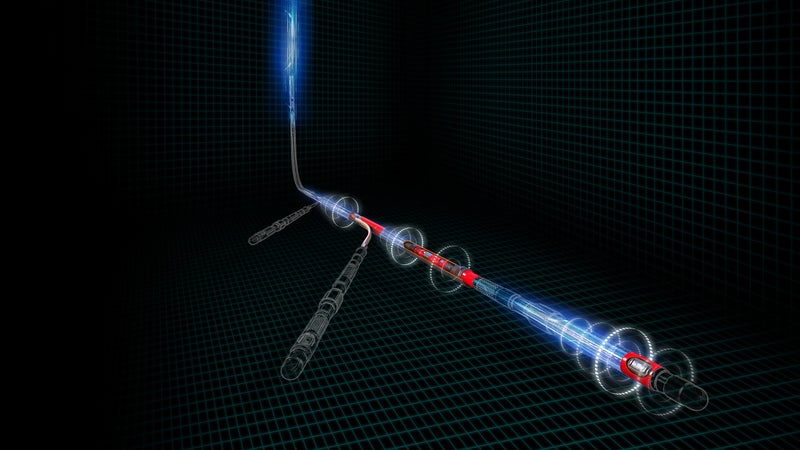

Talk to an expertFor complex, dual-trip intelligent completions, it is essential to verify the integrity of the lower SmartWell® intelligent completion prior to packer setting and upper completion deployment.

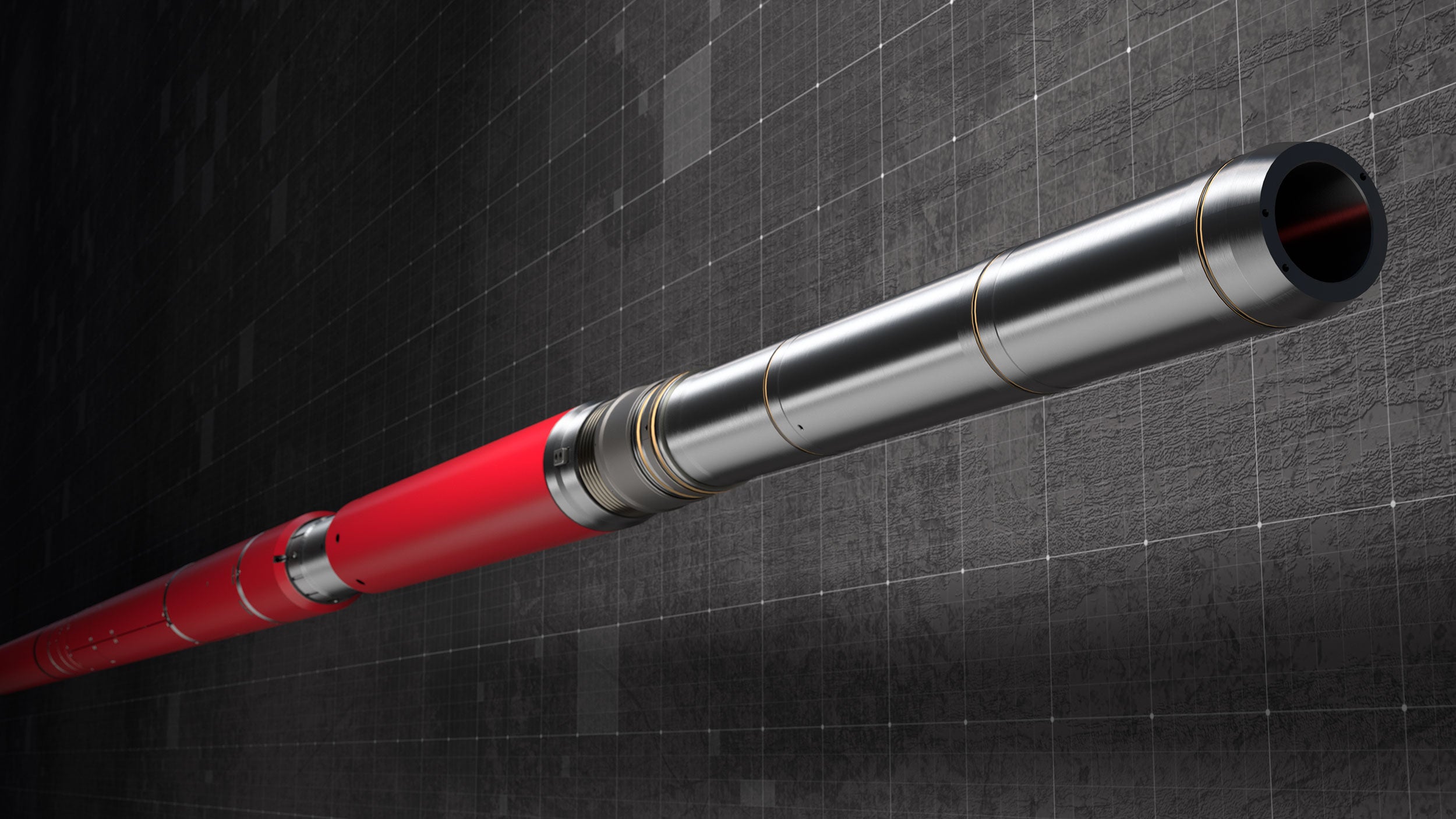

The Auris® integrity checker allows the operator to remotely confirm the integrity of a SmartWell intelligent completion during deployment and at setting depth via a bidirectional signal sent from the surface through the drillpipe. Once the Dynalink® X system acoustic signal reaches the downhole module in near-real time, the system runs a pressure test on the control lines to help hydraulic system integrity. At the same time, the Auris integrity checker can read the entire string of permanent downhole gauges (PDGs) to make sure the electrical system is undamaged; the diagnostic data are then transmitted to the surface for review.

The capability to install upper and lower completions separately reduces intervention time and maintenance costs. It also increases operator confidence when dual-trip completions are run in deeper and more complex well configurations.

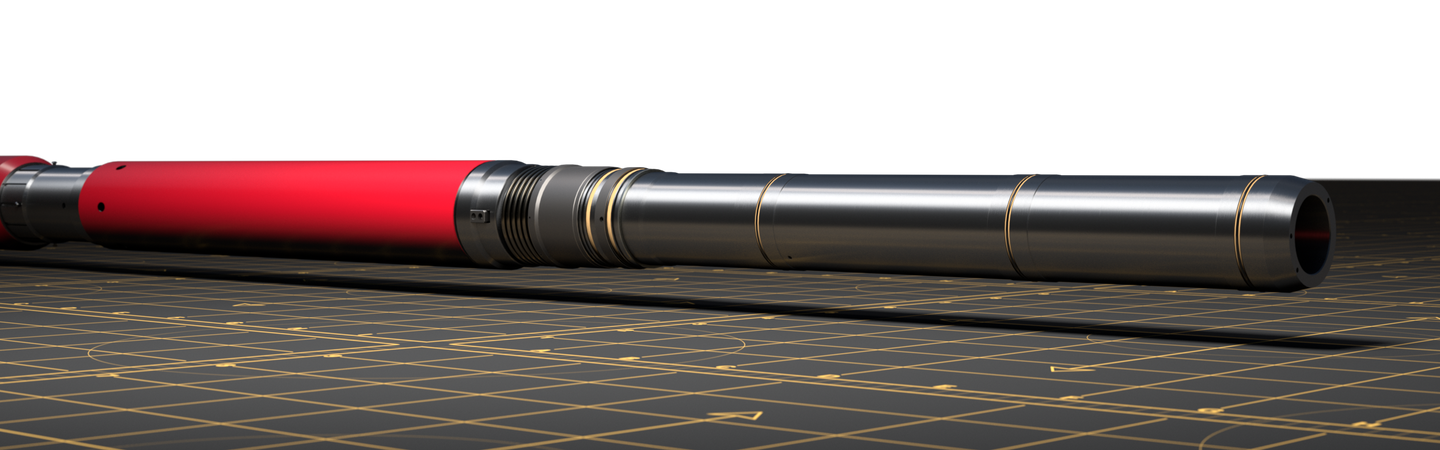

The SmartWell® intelligent completion system is run on drillpipe with the Auris integrity checker and the Fuzion®-EH electro-hydraulic downhole wet-mate connector receptacle. These tools verify line integrity before the production packer is set, the upper drillstring is retrieved, and the reservoir is isolated, all without surface control lines. This configuration reduces clamp installation time and enables quicker SmartWell intelligent completion deployment, resulting in a significant reduction in fluid volume used and/or lost to the reservoir.

Once the SmartWell intelligent completion system reaches setting depth, a bidirectional command is sent from the surface to the Auris integrity checker module at depth. The downhole module’s self-adjusting hydraulic circuit adapts to well conditions to pressure the SmartWell intelligent completion systems or chemical injection (CI) lines higher than hydrostatic, regardless of well temperature, even in managed-pressure-drilling applications. The module can also read and log data from all downhole gauges.

Gauge monitoring allows the operator at the surface to remotely monitor the packer setting sequence from the downhole sensor and verify pressure, which can prove useful in a multi-packer completion string.

Once the packer is set, a command from the surface allows the Auris integrity checker and upper Fuzion-EH electro-hydraulic downhole wet-mate connector assembly to release from the lower completion.

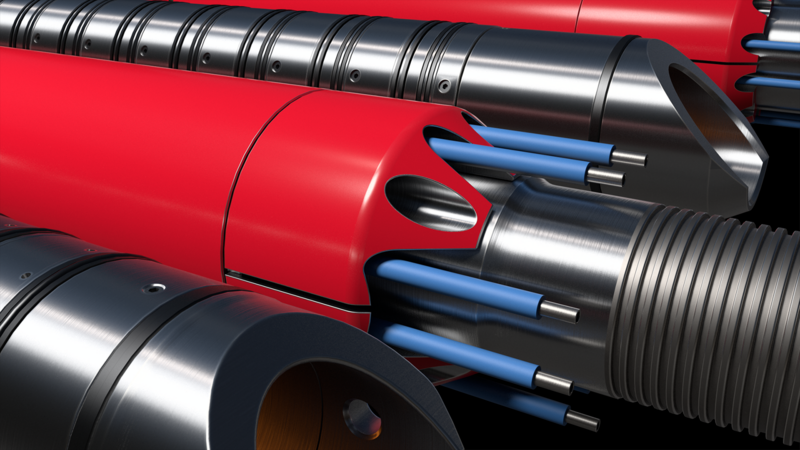

The Auris integrity checker is then retrieved to surface, and the upper completion is run and connected to the lower completion using the upper Fuzion EH electro-hydraulic downhole wet-mate connector. This completes the electrical and hydraulic connections back to the tubing hanger via the upper and lower wet-mate connector systems to provide full SmartWell intelligent completion system control and monitoring capabilities.

Halliburton intelligent completions technology help accelerate production and improve decision-making to increase ultimate recovery and maximize asset value

The Fuzion® suite of wet-mate connectors facilitates removal of the upper completion from the lower completion without using destructive intervention methods.