Search

Search

Search

Search

Oct 20, 2025 | 07:00 AM CST

George R. Brown Convention Center|Houston, TX, US

At Halliburton, quality execution is not just a promise, it is the heartbeat of everything we do. Execution means we collaborate to engineer innovation that reaches the field and turns ideas into smarter designs, intelligent solutions, and more efficient operations.

Together with our customers, we achieve greater well economics through groundbreaking drilling and completions technology. We extend asset life through advanced production monitoring and optimization solutions. And through leading digital capabilities in enterprise software, intelligent automation, and artificial intelligence, we redefine what is possible—from well planning through late‑life recovery.

For us, innovation is more than technical ingenuity—it is safety and reliability fused into every step to power superior outcomes that unlock asset value across the entire lifecycle. The result? Consistent, measurable performance and lower total cost of ownership for our customers.

Join us at SPE ATCE from October 20-22 in booth #412 to experience how innovation, collaboration, and execution come together to deliver results that push the industry forward.

This is Halliburton—where innovation meets execution.

special session

Data to Decisions: Staying at the Forefront of Advanced Computing, Simulations & Analytics

special session

The Challenges, Needs, and Potential Solutions for the Future of Offshore Completions - Annual Technical Conference and Exhibition 2025 (25ATCE)

DecisionSpace® 365 solutions from Halliburton deliver digital solutions at almost every step of the drilling process.

Increase the consistency and performance of well construction operations by integrating subsurface automation, digital twins, and remote operations.

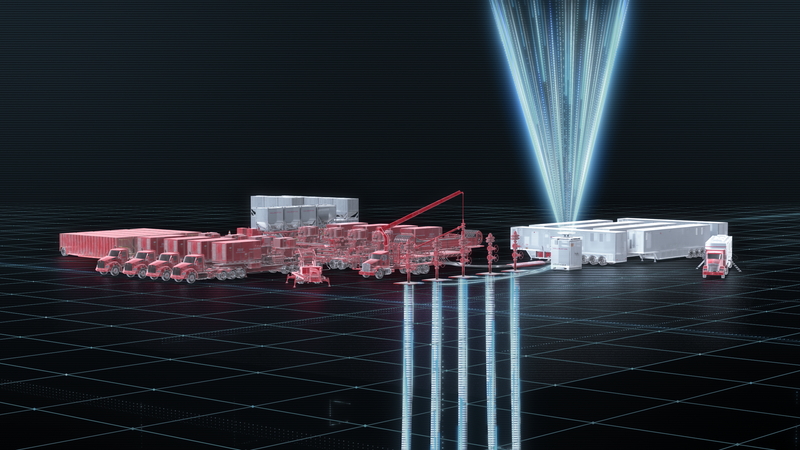

Industry’s first intelligent fracturing platform that gives customers control of asset performance.

OCTIV Auto Pumpdown service controls fluid pumps and a wireline unit as a single, fully automated, closed-loop system to maximize plug and perforating performance.

Providing improved ESP system optimization and extensive customizable well monitoring to meet all your production needs.

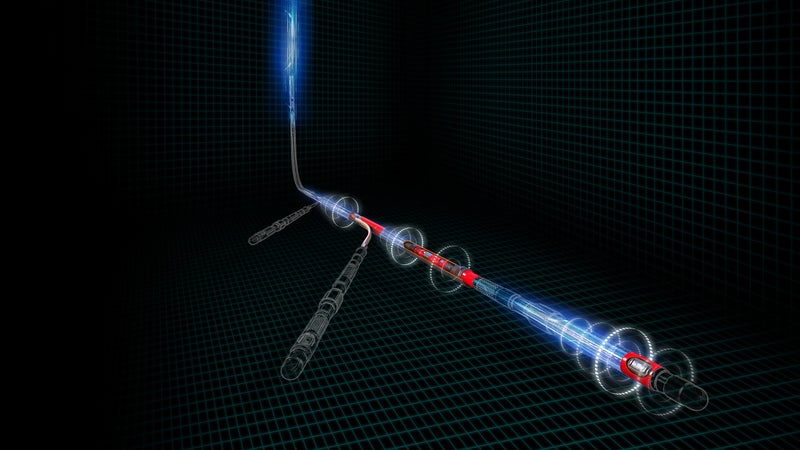

Halliburton intelligent completions technology help accelerate production and improve decision-making to increase ultimate recovery and maximize asset value

Control, measure, and analyze surface well testing through automated workflows.

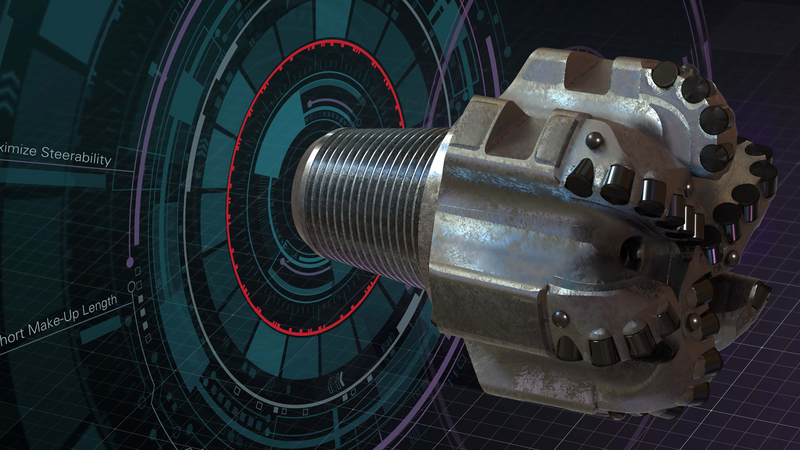

Custom drilling solutions for increased performance, more accurate planning and monitoring, and greater risk mitigation and safety.

Directional drill bits designed for high build rates in curve and lateral applications.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.

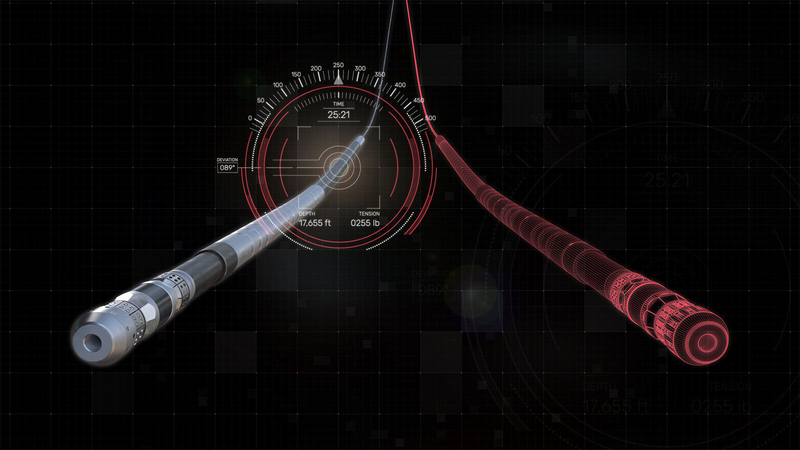

The ClearTrac tractor service is the most advanced wireline conveyance technology on the market for highly deviated or horizontal wells.

Halliburton’s Low Carbon Solutions and low carbon technologies are enabling a balanced energy transition for a sustainable future.

| Title | Room |

|---|---|

| Advances in Formation Evaluation and Well Testing for Energy Transition | Room 342BE |

| EGS Propped Stimulation >300°C: From Design To Implementation To Learnings Phase I | Room 320C |

| An Accurate Yet Simple Method ToEstimate Caving Volume For Real-time DrillingOperation | Room 322 |

| Title | Room |

|---|---|

| Well Life Cycle Data Management – From Portfolio Ranking, Design Concept through Plug & Abandon | Room 322 |

| Optimizing Multilateral Well Operations:Advanced Taml-5 Completion systems For Enhanced Lateral Access And Operational Efficiency | Room 332CF |

| Establishing A New Pioneering Benchmark In Enhancing Safety And Efficiency: A Unique Integration Of Kinetic Shearing Bop In Gate Valve Drilling Operations | Room 322BE |

| An Effective Scale Inhibitor And A TailoredAcid Cleanout Successfully Maintains Well Productivity After Severe Scale Formation In A Mature Gas Producing Field: Case History In A Subandean South Field | Room 342CF |

| AI-driven Geology: Vision Rags DecodingLegacy Report Using Colpali | Room 340 |

| Decommissioning A Gas Processing Offshore Hub Pipeline And Installing A Subsea Bypass System To Operate Without Platform In The Norwegian North Sea | Room 342BE |

| Production Surveillance | Room 332AD |

| Innovative Techniques and Technologies in Well Completion, Simulation, and Artificial Life: Enhancing Efficiency, Diagnostics, and Performance | Room 320C |

| From Capture to Storage: Next-Generation Technologies for CO2 Management | Room 332CF |

| Promoting Stem In The Energy Regions: A Driver Of Progress And Technological Transformation | Room 332BE |

| Optimizing Oil Field Development With Multi-action Decision-making In Deep Reinforcement Learning | Room 330 |

| Title | Room |

|---|---|

| Unconventional reservoirs | Room 332CF |

| Advancing Rig Efficiency, Drilling Performance, and Operational Resilience | Room 330 |

| Next-Generation Fluids: Sustainable Solutions and Performance Optimization | Room 322 |

| Rock and Fluid Properties: Shaping Reservoir Performance | Room 330 |