Search

Search

Search

Search

New solution provides corrosion-resistance for long-term barrier support.

HOUSTON – January 29, 2024 – Halliburton Company (NYSE: HAL) today added the CorrosaLock™ cement system to its growing carbon capture, utilization, and storage (CCUS) portfolio.

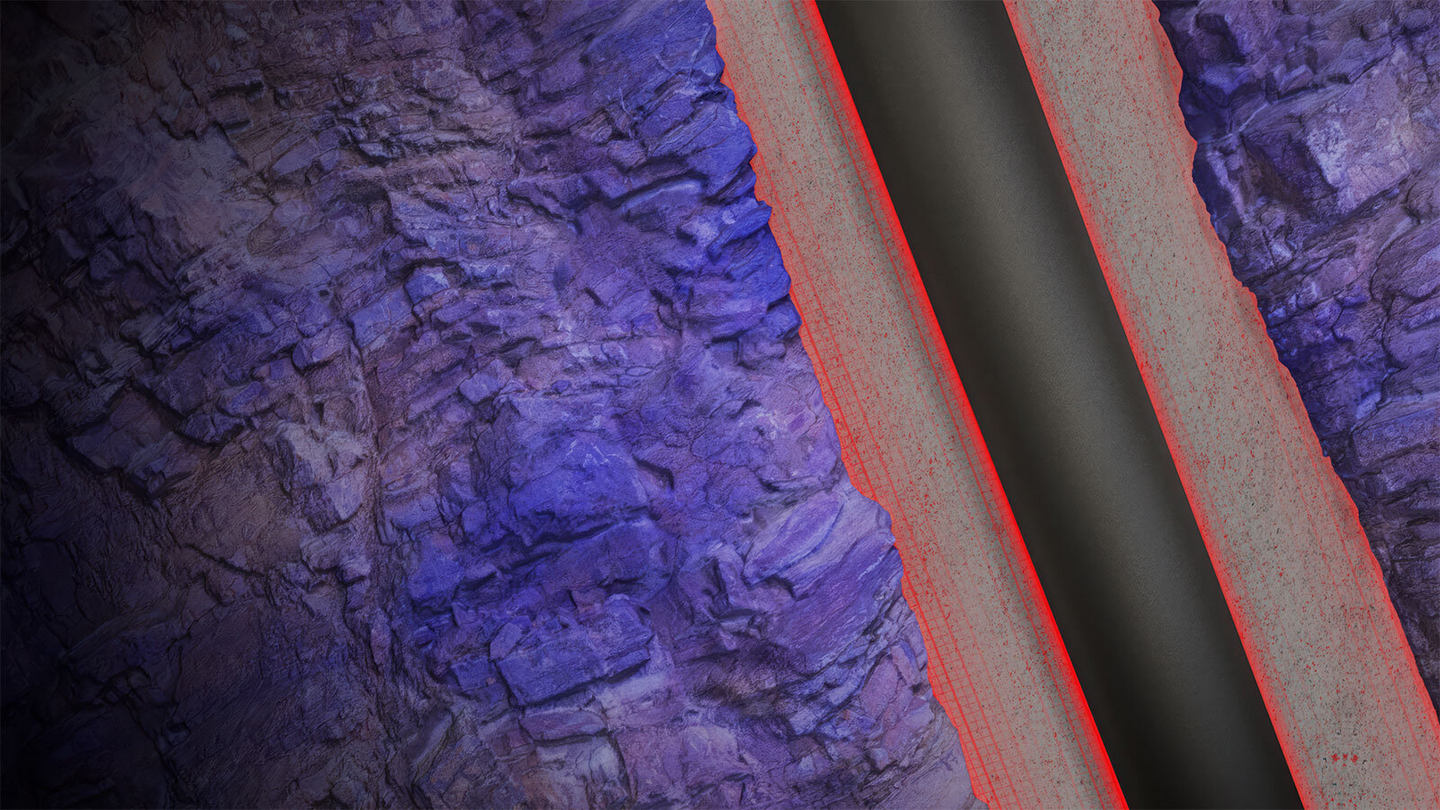

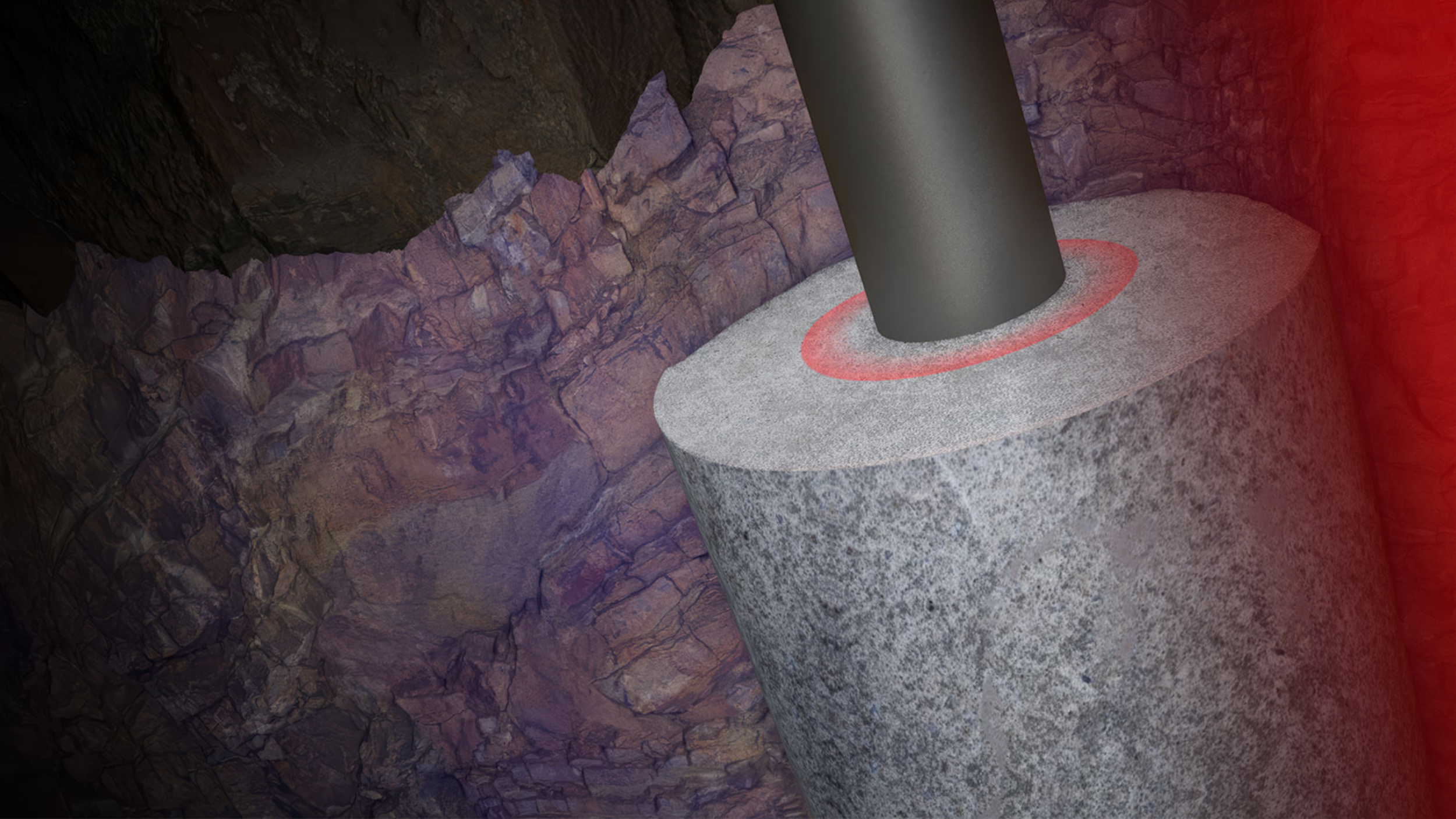

The CorrosaLock cement system, which is designed for CO2 storage, is a composite of Portland-based cement and Halliburton’s proprietary WellLock® resin system. The incorporation of resin generates a film on the composite surface that creates a coating effect that aids in bonding. Resin also reduces the system’s effective porosity and forms an adhesive layer to help protect cement from CO2 degradation. The result is enhanced cement sheath elasticity and shear bond strength that allows the barrier to better withstand downhole forces during cyclic injection and provide increased anchoring force to the formation when compared to conventional cement systems.

Cementing wells for CCUS presents unique challenges. These projects aim for permanent underground CO2 storage, which requires long-term cement sheath integrity. The significant permeability reduction and enhanced mechanical properties of our CorrosaLock system address those challenges for our customers and builds on Halliburton’s decades of experience designing annular barriers for corrosive environments

The CorrosaLock system joins the WellLock ® resin system, ThermaLock™ cement, and CorrosaCem™ cement system as part of Halliburton’s advanced CCUS portfolio.

About Halliburton

Halliburton is one of the world’s leading providers of products and services to the energy industry. Founded in 1919, we create innovative technologies, products, and services that help our customers maximize their value throughout the life cycle of an asset and advance a sustainable energy future. Connect with us on LinkedIn, YouTube, Instagram, and Facebook.

Press Contact:

Andrew Knotts

PR@halliburton.com

281-871-2601