Search

Search

Search

Search

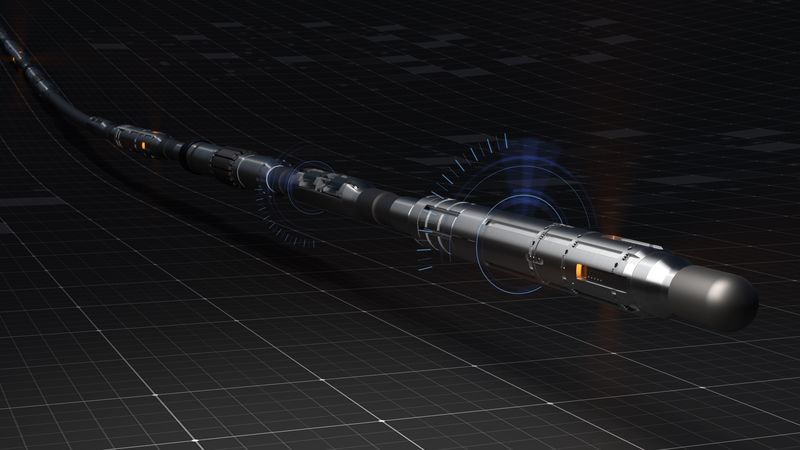

Halliburton has led the industry in intelligent completions technology for 25 years and was the first to introduce SmartWell® systems

Talk to an expertHalliburton SmartWell completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data while also controlling and monitoring selected reservoir zones remotely and in real-time.

With 25 years of expertise, our systems can help you accelerate production and improve decision-making, allowing you to increase ultimate recovery and maximize asset value.

Article

Read ArticleThe technology is being pushed even further, where now we can have tremendous amount of control over multiple reservoirs all from a single well

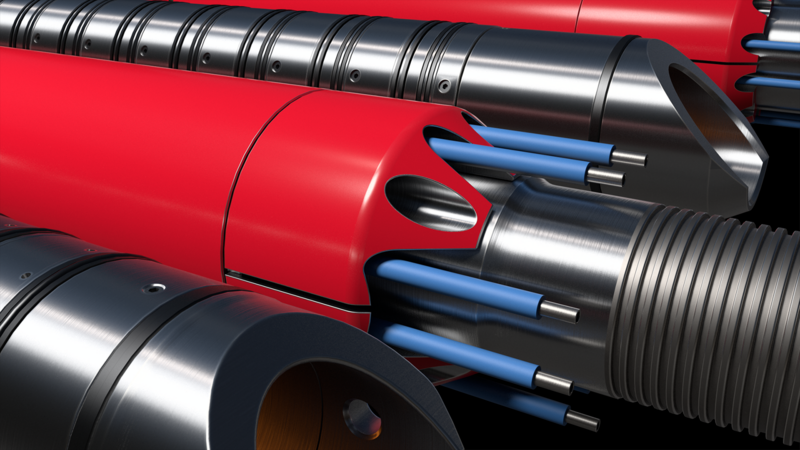

Halliburton Company achieves an industry first in downhole electric completion technology with Petrobras in deepwater Brazil

Read press release

Halliburton received three 2023 Meritorious Awards from Hart Energy. One of the three awards was recognized in the Non-Fracturing Completions category for Fuzion®-EH electro-hydraulic downhole wet-mate connector.

Read press release

Collect, transmit, and analyze downhole data, and remotely control and monitor reservoir zones with Halliburton SmartWell® completion systems.

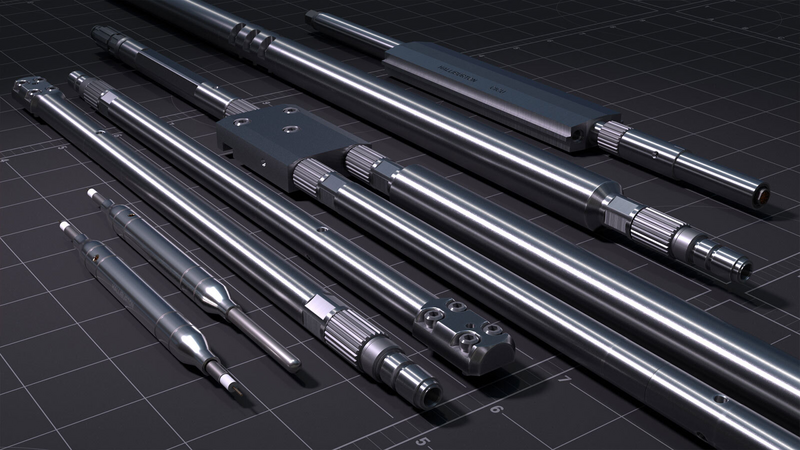

The DataSphere permanent monitoring suite is a robust combination of the best in sand control, multilateral and intelligent completion technology.

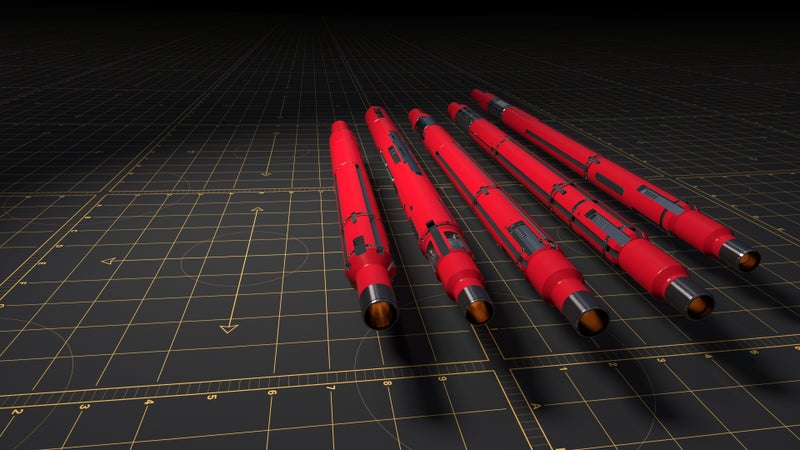

Halliburton eMotion valves provide interventionless remote control of hydraulically actuated completion equipment, eliminating multiple wireline runs.

The Fuzion® suite of wet-mate connectors facilitates removal of the upper completion from the lower completion without using destructive intervention methods.

Halliburton intelligent flow control systems provide a method to integrate manual or automated surface control systems with downhole SmartWell® completion equipment.

Clariti View is an integrated service that provides real-time downhole gauge pressure and temperature information