Search

Search

Search

Search

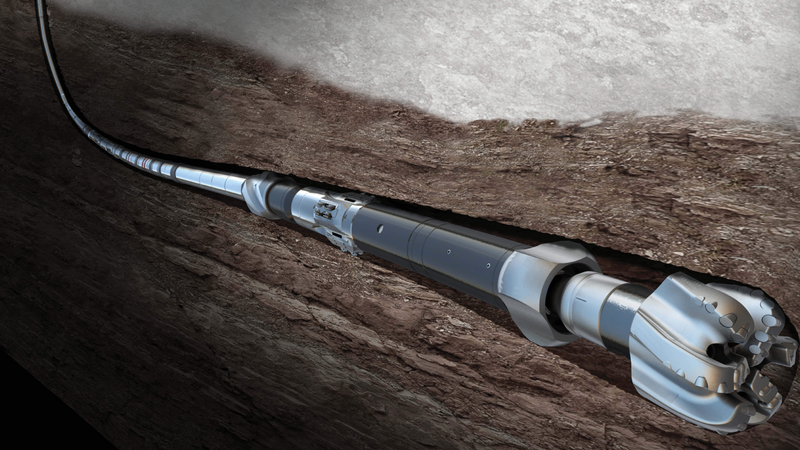

Halliburton reservoir drilling fluid solutions are engineered to safeguard well construction and minimize damage to the producing zone.

Talk to an expertWe pioneered the study of reservoir drilling. Today, Halliburton solutions preserve permeability and can improve productivity to the reservoir rock’s native potential. Producing zones require protection and attention at all costs.

Halliburton completion fluids optimally prepare, repair, clean out, and complete the wellbore to maximize production.

Explore

Customized filtration solutions maximize filtration and ensure environmental compliance for fluid discharge.

Explore

Baroid’s breaker systems remove filter cake to improve productivity or injectivity of treated wells.

Explore

Reduce or eliminate differential pressure across the packer with Baroid’s packer fluids, extending packer life and reliability.

Explore

Proven corrosion-control treatments that mitigate the corrosive qualities of drilling, completion fluids, and other downhole factors.

Explore

BaraKlean® cleaners promote wellbore cleanliness to lower costs and boost production.

Explore