Search

Search

Search

Search

Offering a lower emissions profile and reducing fuel costs

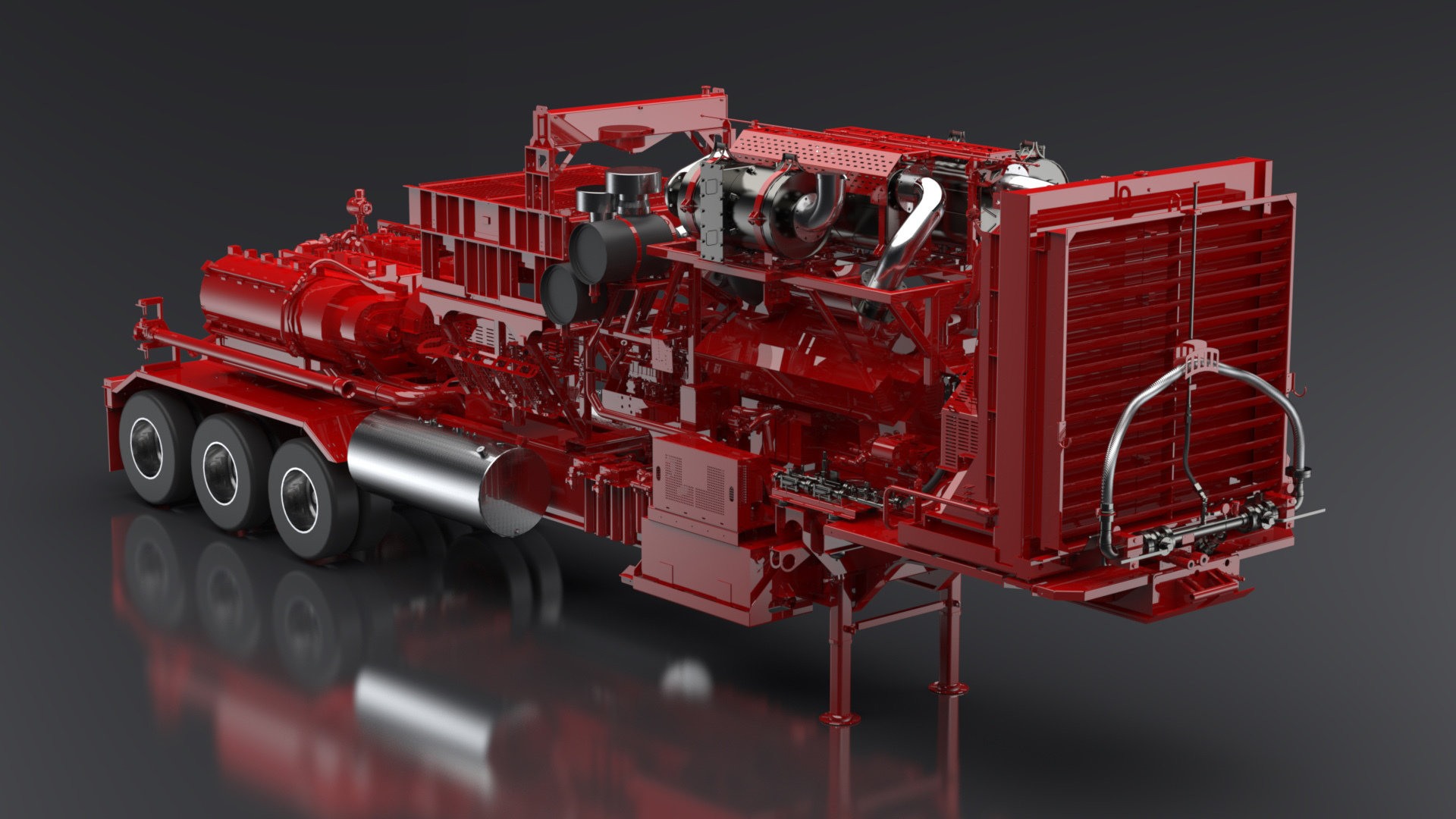

talk to an expertIn hydraulic fracturing operations, diesel fuel is a significant expense. A proven way to significantly reduce fuel consumption is to use dual fuel operations, which means operating a diesel engine on a combination of both diesel fuel and natural gas simultaneously.

Dual fuel systems allows operators to power the fracturing fleet with 70 percent field gas and only 30 percent diesel. These engines can switch seamlessly between diesel-only and dual fuel operations, preventing unwanted disruptions and downtime, while reducing footprint by 15 percent. Additionally, they adhere to the tier 4 EPA emissions standards which are about 35 percent lower than tier 2 dual fuel systems.

DID YOU KNOW

Dual Fuel ADVANTAGES

Diesel Substitution

Lower Emissions (Compared to T2 Dual Fuel)

Reduced Footprint (Compared to Competition)

Fuel Cost Savings (Compared to Conventional Fleet)

Dual fuel systems deliver a mixed fuel solution with no sacrifices on horsepower or reliability, and are easily used with our efficient Q10™ pumping unit . They are also designed with rigorous safety standards, having all equipment located outside the red zone.

Dual fuel equipment rig-up is built for quick set up and flexible onsite layout. These systems also offer operators safe and easy access to inspect the equipment during the job.