Search

Search

Search

Search

Technology integration sets a new performance benchmark

Download PDFMature Fields

Intersect multiple reservoirs, and identify waterflooded zones while drilling

United Arab Emirates

Horizontal, offshore wells in the UAE have been planned and completed for decades with the goal of increasing well productivity or injectivity while limiting water coning through reservoir flow modeling based on local Sw and porosity. Intersecting two reservoir layers in one horizontal section is an effective method, but it requires advanced geosteering solutions and directional control to place the well within the geological targets while delivering a quality open hole suitable for complex completions.

An operator planned to maximize offshore production in a mature carbonate field by targeting multiple carbonate layers. The subject well targets two carbonate reservoir layers by means of a single 8.5-in. horizontal section. The drilled footage along each formation was approximately 4,000 ft of lateral length, totaling 8,000 ft MD. Real-time reservoir insight was necessary while drilling to identify potential waterflooded/slumping zones.

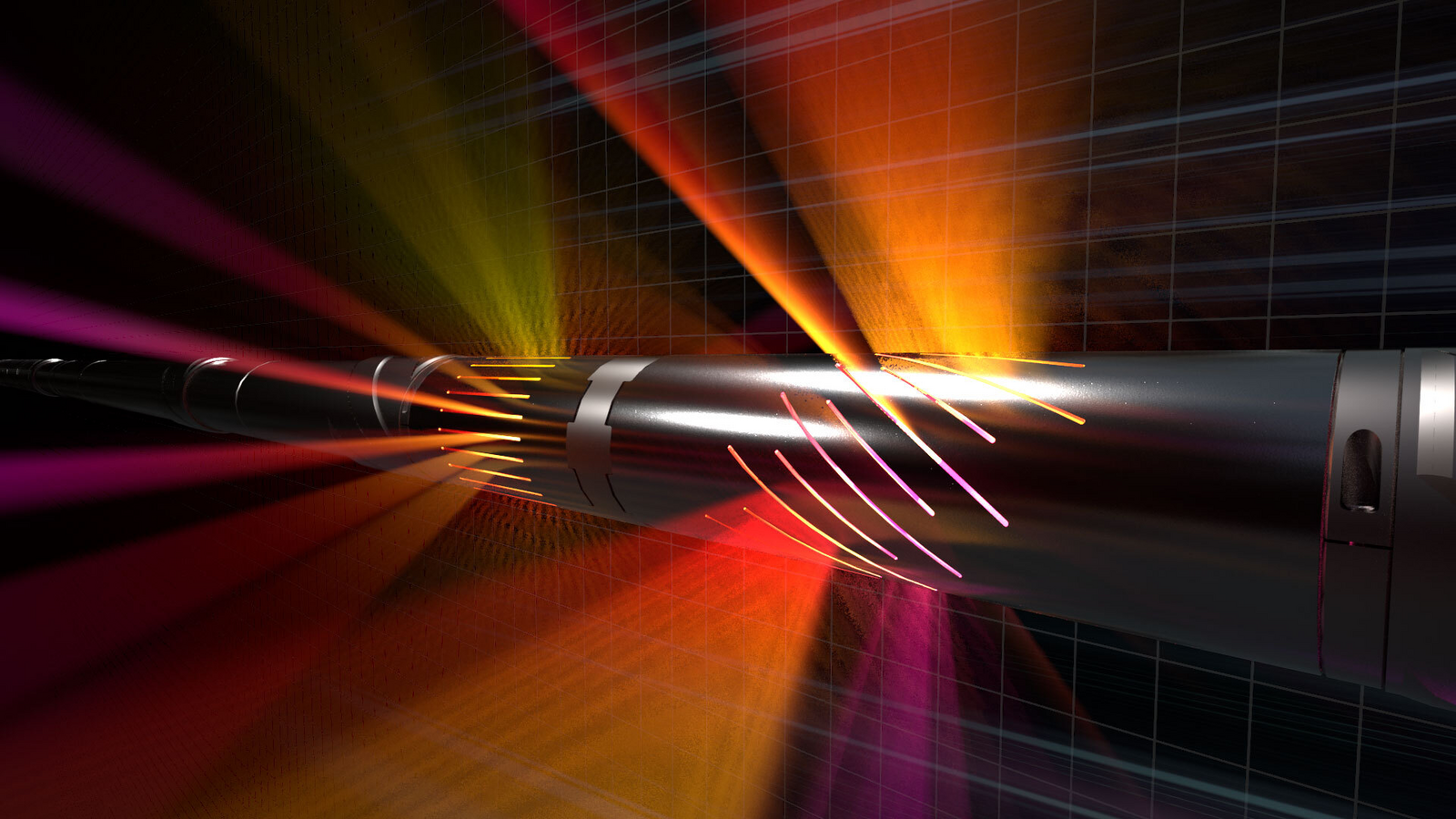

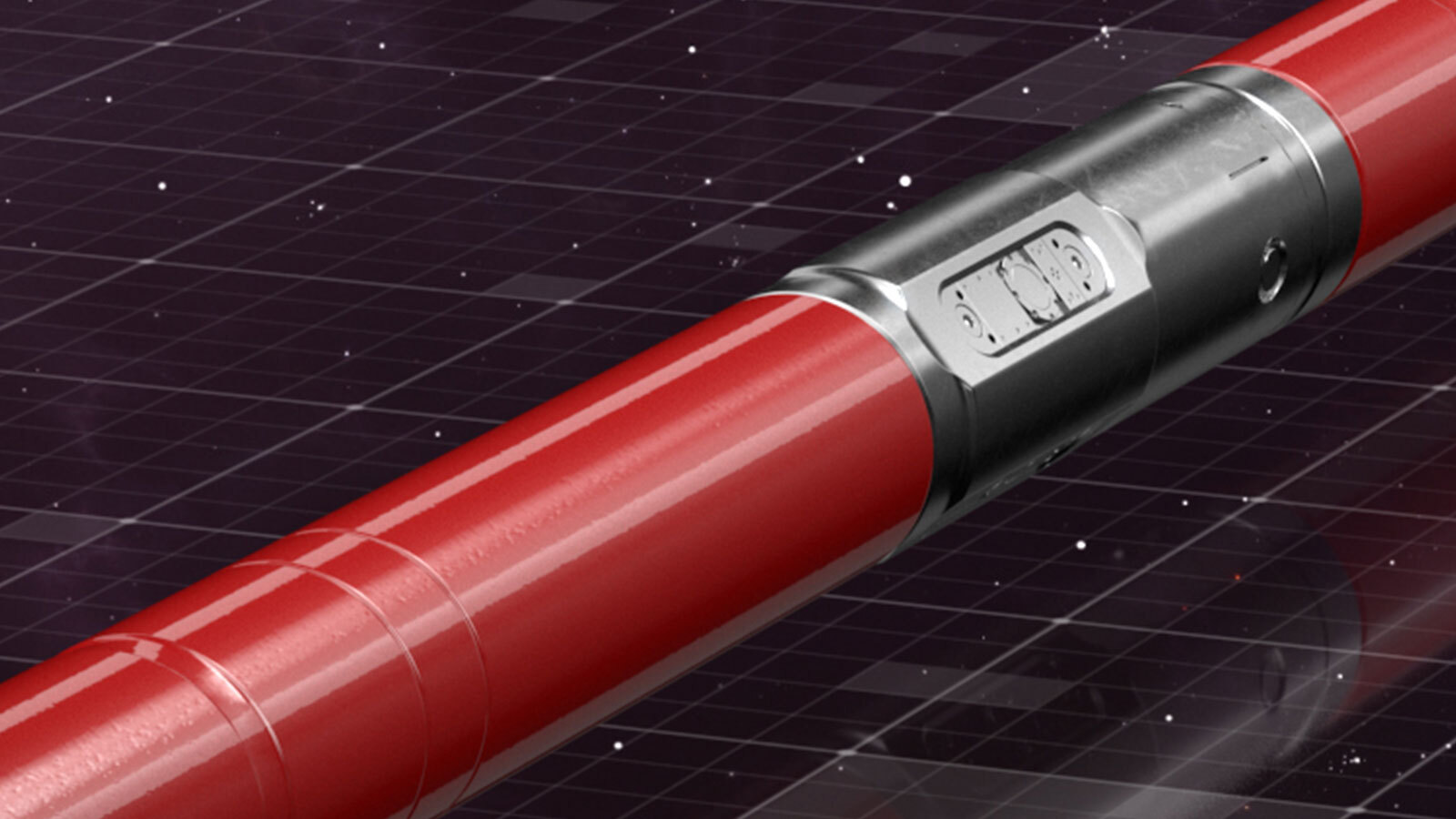

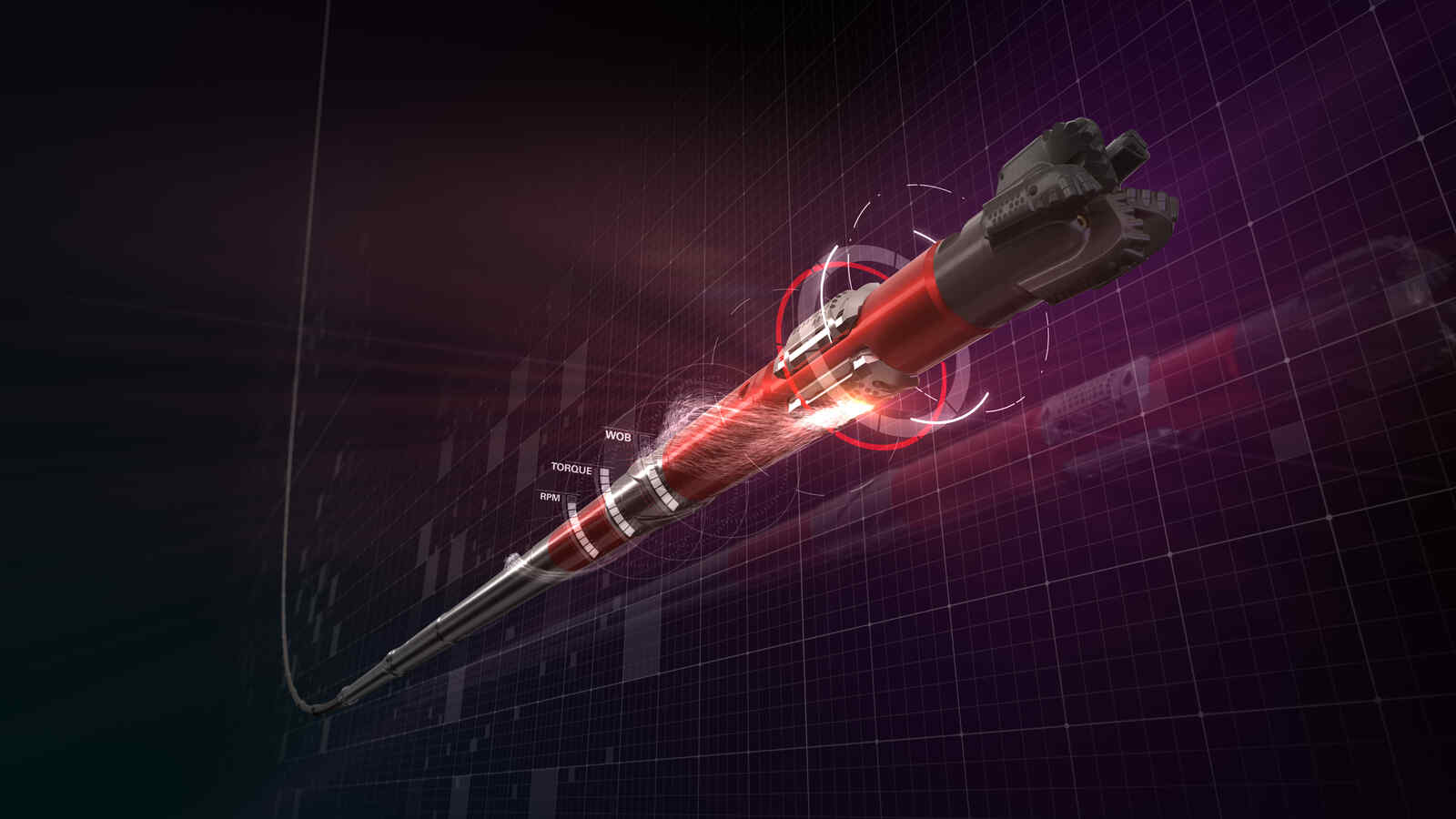

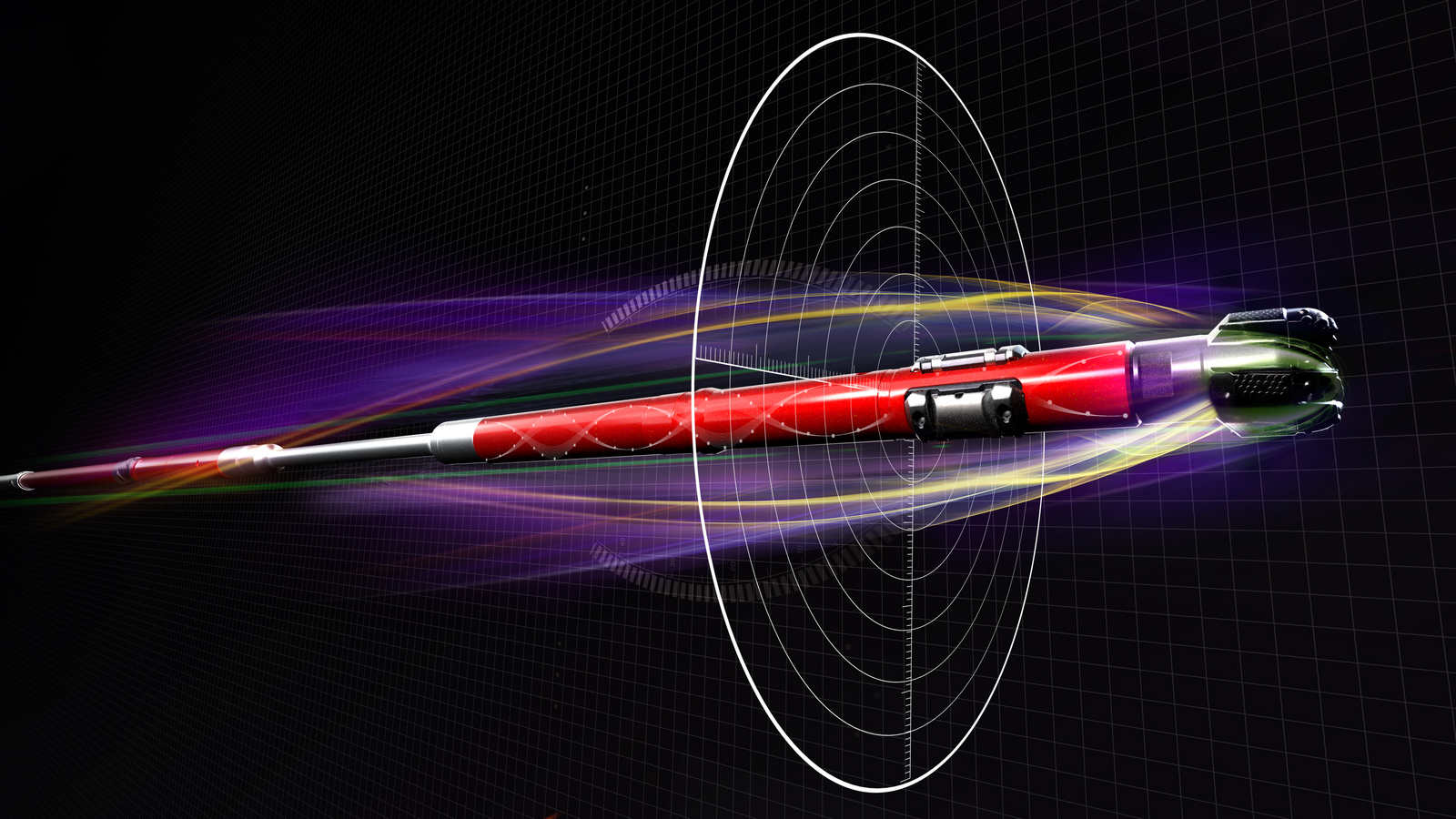

The EarthStar X near-bit, shallow and ultra-deep resistivity service was deployed with a triple combo BHA and the iCruise® Rotary Steerable System (RSS) to enhance well placement and map formation and fluid boundaries all around the wellbore in real-time. Aided by simultaneous geomapping to provide advanced 1D/3D inversion processing in real-time, the acquisition of the triple-combo data closer to the bit used the iStar® Intelligent Drilling and Logging Platform that further enhanced early access to geological changes. The BaseStar service (12-ft long collar) incorporated multiple sensors (gamma ray, directional surveys, downhole drilling dynamics, and WOB/TOB). The EarthStar X service transmitter was placed 50 ft from the bit to provide inversion technology and actual shallow phase/attenuation resistivity measurements. This transmitter can be placed closer to bit (~9 ft). Using 3D ultra-deep resistivity mapping technology, the operator was able to identify waterflooding/slumped zones and make informed steering decisions more quickly. This method, driven by technology integration, reduced rig time and allowed the completion design to be optimized in real-time while setting a new benchmark for future operations in the area.

With the iStar platform and iCruise RSS, the BHA provided measurements to aid geosteering operations and allow for early decisions to avoid abrupt adjustments and limit tortuosity with a minimum tolerance of 0.1 in., a critical factor in similar long wells. The combination of high-resolution measurements, including borehole caliper imaging, continuous surveys, downhole drilling dynamics (WOB/TOB), pressure while drilling (PWD), and downhole string vibration helped achieve accurate geometric wellbore positioning, optimize the drilling process, and ensure a flawless operation to TD, all within one 13.4 ft collar.

The 1D/3D inversion technology from the EarthStar X service helped identify a conductive zone above and below the borehole at the heel, in addition to a conductive zone above the wellbore toward the section TD. This was interpreted as waterflooding and slumping, vividly displayed in the azimuthal resistivity images. The direction of the low conductive zone was identified to have originated from the top-left side of the trajectory, indicating alignment with the nearest offset well above.

The reservoir mapping results increased the confidence of the completions and production teams to finalize blanking sections and deliver the design in a timely manner while isolating the zone at risk of water breakthrough. This helped the reservoir surveillance team optimize future well placement to avoid drilling in water saturated zones, estimate remaining oil saturation, and support far field formation evaluation applications. This run set a new benchmark for delivering superior drilling performance, industry-leading subsurface insight, and consistent well delivery to maximize asset value for the operator.

Near-bit, shallow, and ultra-deep resistivity service that enables accurate reserves evaluation to help place wells in the productive zone of the most complex reservoirs.

Ultra-deep resistivity service mapping reservoir and fluid boundaries up to 225 feet from the wellbore.

Integrates critical measurements for wellbore placement, drilling performance optimization, and borehole quality.

Provides accurate reserves calculations with geological and petrophysical interpretations.

Designed for longer well applications in harsh environments.

Designed for fast drilling, accurate well placement, and reliable performance.

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.