Search

Search

Search

Search

Deep Water

Design a drilling fluids system for drilling in deep water

Offshore, The Netherlands

A Dutch operator was faced with the challenge of drilling various slimhole wellbores containing a narrow hydraulic window into the Carboniferous-aged Rotliegend reservoir formation in the North Sea, offshore the Netherlands. The well targets were reached by first drilling through the Zechstein salt formation and the Silverpit and Lower Slochteren formations, which are all depleted formations.

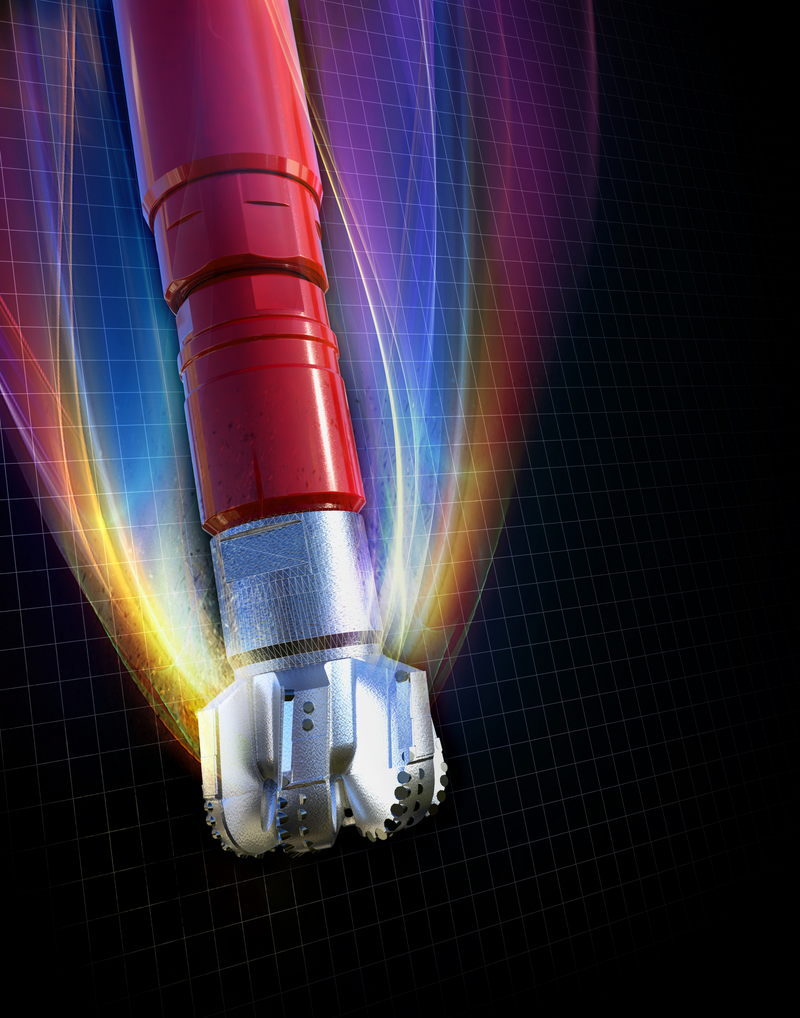

The operator challenged Baroid to drill the Zechstein and Rotliegend formations in one section, referred to as ZeRoOne. The decision to drill ZeRoOne was based on risk and value assessments for extending field life and maximizing production in the mature asset. The primary factor in the basis of the fluid selection was designing a fluid system capable of delivering low equivalent circulating density (ECD) margins, thus mitigating the risks involved in drilling a 1,200-meter (3,937-foot) section through the overburden and into the reservoir.

Although many high-performance non-aqueous fluid (NAF) systems were potential solutions, many of these fluids do not display the necessary low ECD margins. Baroid implemented its Technical Process with extensive testing to customize a fluid solution that matched, and, for several properties, surpassed the customer-specified design targets. As a solution, Baroid recommended using the high-performance and clay-free BaraECD® NAF system. BaraECD fluid has a rheological profile designed to provide low, controlled ECD in wells with narrow pore pressure/fracture pressure gradients, thus reducing the risk of drilling-induced fractures. The design mud weight was set at 13.52 lb/gal (1.62 SG) with an expected fracture gradient of 14.35 lb/gal (1.72 SG). Although there was a relatively wide margin, there was a marked downside risk, and it was difficult to quantify a lower fracture gradient in an overburden-reservoir transition zone because of depletion.

The BaraECD NAF system delivered ECD values within the critical mud-weight window, minimizing the risk of influx and/or losses over the upper part of the sections. ECDs ranged from 14.20 lb/gal to 14.33 lb/gal (1.70 SG to 1.72 SG), allowing the operator to successfully drill the well and penetrate the depleted reservoir, and overcoming drilling challenges through the Lower Slochteren formation. In contrast, conventional NAFs, when simulated, showed much higher ECD values ranging from 14.91 lb/gal to 15.33 lb/gal (1.79 SG to 1.84 SG).

However, as the drilling operation reached the top of the reservoir, a fracture gradient of 12.27 lb/gal (1.47 SG); a result of depletion, was found instead of the planned 14.32 lb/gal (1.72 SG), resulting in total losses. The BaraECD system faced another challenge, which was to overcome the losses and regain wellbore stability, and this was achieved on the first attempt with a customized lost circulation material (LCM) formulation.

Despite the complexity of the drilling operation, Baroid and the operator managed to reach the top of the reservoir with the BaraECD NAF system. For more information, please refer to SPE paper SPE-180633-MS.

The successful trial application of the BaraECD NAF system while drilling the ZeRoOne objective allowed for more challenging, longer step-outs, and for directional and extended-reach drilling (ERD) wells to be drilled as part of the ongoing extended-life field development, thus providing access to additional areas of the reservoir.

It was concluded that the technical objectives of the well would not have been achieved without the use of the BaraECD system, which was recognized both as a technical and an environmental success.

Mitigate pressure challenges and simplify completions with our most advanced NAF

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.

Directional drilling systems engineered to reduce well time and maximize reservoir contact from unconventional land to extended-reach deepwater drilling.