Search

Search

Search

Search

Reduced Portland cement blends, automation, and digital technologies to minimize carbon footprint.

Talk to an expertThe Energy Evolution is an opportunity for Halliburton to do what we do best: innovate, collaborate, and execute to drive efficiencies and affect change, including lowering the emissions profile of our technologies and our internal activities. These opportunities for innovation and growth will improve our overall sustainability, while helping our customers decarbonize their legacy production base.

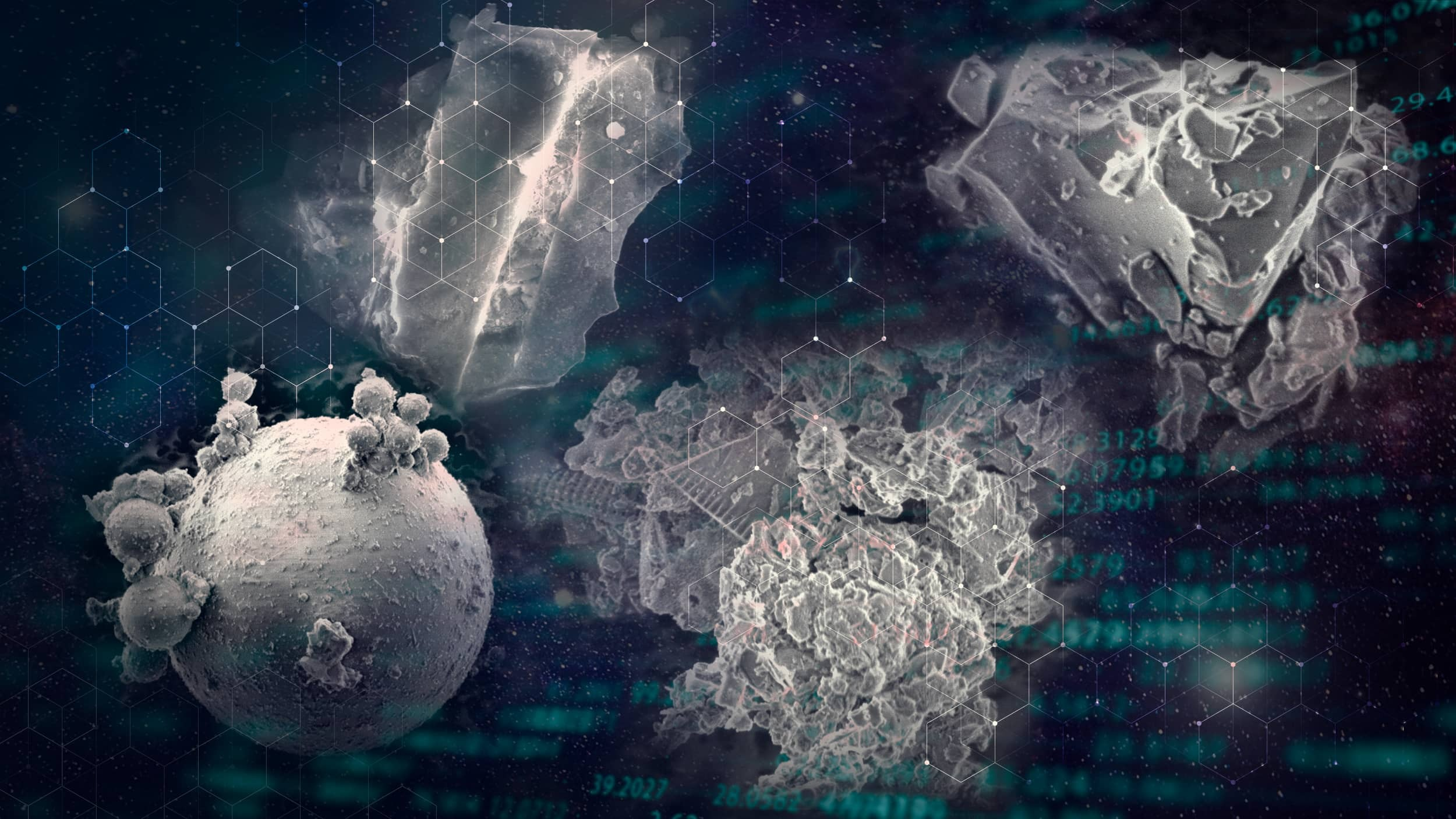

Cement is one of the most consumed products on the planet and contributes to greenhouse gas (GHG) emissions by releasing CO2 and other pollutants during the manufacturing and transport processes. In oil well cementing, Portland cement accounts for upwards of 99% of the mass of the slurry design and the majority of the carbon footprint. In order to lower emissions related to cement designs, Halliburton offers a range of tailorable, reduced Portland systems.

NeoCem™ Cement System - Reduces the amount of Portland cement in the wellbore isolation barrier by an average of 40% by mass Portland.

NeoCem™ E+ Cement System - An extension of the NeoCem Cement blend portfolio that further reduces the amount of Portland cement in the wellbore isolation barrier with 30%-50% mass portland.

EnviraCem™ Cement System - The next generation of reduced Portland cement systems containing less than 30% mass Portland content to even further reduce environmental impacts. EnviraCem cement system will be launched in 2022.

Halliburton is committed to mitigating the environmental impacts of our operations through increased efficiency and investments in R&D to reduce energy use and emissions from the equipment we design, manufacture and use.

Our carbon footprint relates to the GHG emissions associated with our operations, which are inclusive of raw materials, facilities, logistics and our work on location. In order to track progress on reduction of GHG emissions and achieve sustainability goals, it is imperative to have accurate CO2 baseline tracking, reporting, and metrics.

At Halliburton, we are actively working on creating an intelligent system capable of tracking the carbon footprint for the products and services that we provide. This system will be able to analyze the footprint of a job based on a tailored design that minimizes carbon footprint, produce a pre-job carbon footprint estimate, and provide a validated, post job sustainability label.