Search

Search

Search

Search

Our people, proven processes, chemistries, expertise, and digitally enabled workflows deliver solutions and service to help you achieve performance excellence.

Talk to an expertMulti-Chem provides unparalleled service, technical expertise, and customized specialty chemicals for oilfield, downstream, and heavy industrial operations.

MULTI-CHEM DIFFERENCE

Operators face difficult demands, such as maximizing production, complying with regulations, controlling costs, and minimizing non-productive time. Service excellence matters will help you achieve success. Four pillars of operation — training and competency, account management standards, value creation, and the APX™ digital platform — set the stage for Halliburton to execute and consistently improve your programs.

Learn MoreHYDROCARBON ENGINEERING / OCTOBER 2023

One of our leaders sat down with Hydrocarbon Engineering to define what service excellence means to the upstream, midstream, and downstream chemical markets.

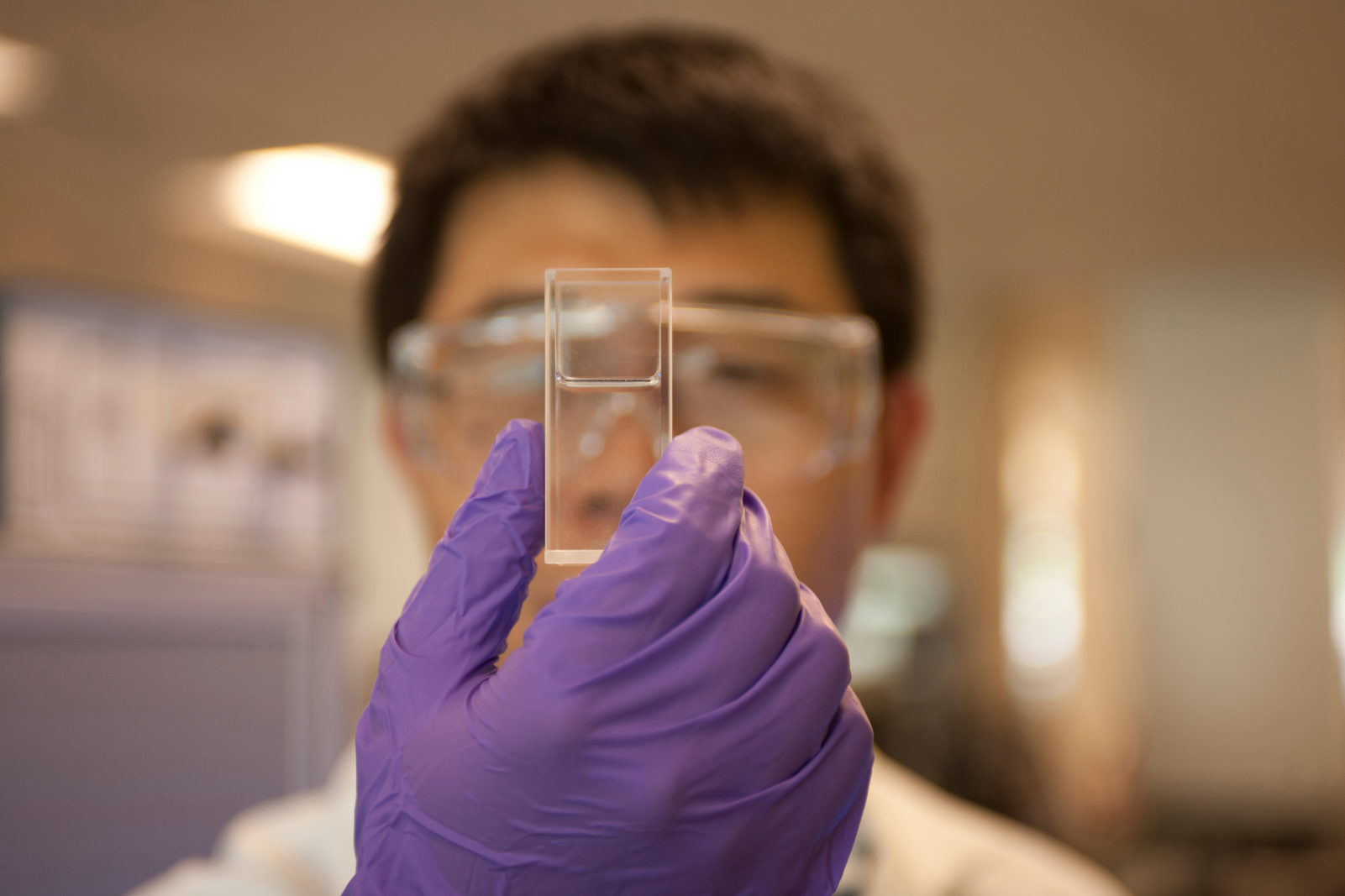

read full articleProviding engineered chemical solutions to maximize oilfield production is the operating directive for Halliburton Multi-Chem laboratories worldwide. We collaborate with our customers to understand their challenges. We then apply our command of oilfield chemistry to resolve issues within our regional and global laboratories to deliver differentiated insights and recommendations.

learn moreMulti-Chem invests heavily in training and annual competency programs to deliver superior service. This allows us to deliver unparalleled service, technical expertise, and customized specialty chemicals for oilfield, downstream, and heavy industrial operations.

To ensure we consistently deliver high-quality service, our account management standards drive alignment with your goals, communication, and collaboration. Documented processes drive consistent execution across all assets.

For several decades, Multi-Chem has delivered tens of millions in savings through our value-creation process. Value means a return on your investment and optimizing operations. A value improvement project often has quantifiable dollar savings and/or operational and technical efficiency enhancements.

The Analyze Performance Execution (APX™) digital platform delivers predictability and value creation. Connect financial, operational, analytical, and supply chain data with your assets to understand risks, and predict and prevent problems before they occur.

Learn More

Solutions that address traditional and unique oilfield challenges with chemistry and applications expertise.

Explore

Prevent and correct midstream failures with Halliburton midstream chemistry, system modeling, maintenance, and optimization.

Explore

Halliburton helps enhance downstream operations through water and process treatment programs that deliver specialized chemicals, analysis, and more.

Explore

Halliburton provides chemical manufacturers and industrial customers with reaction manufacturing and blend tolling capabilities and multi-step reactions.

Explore