Search

Search

Search

Search

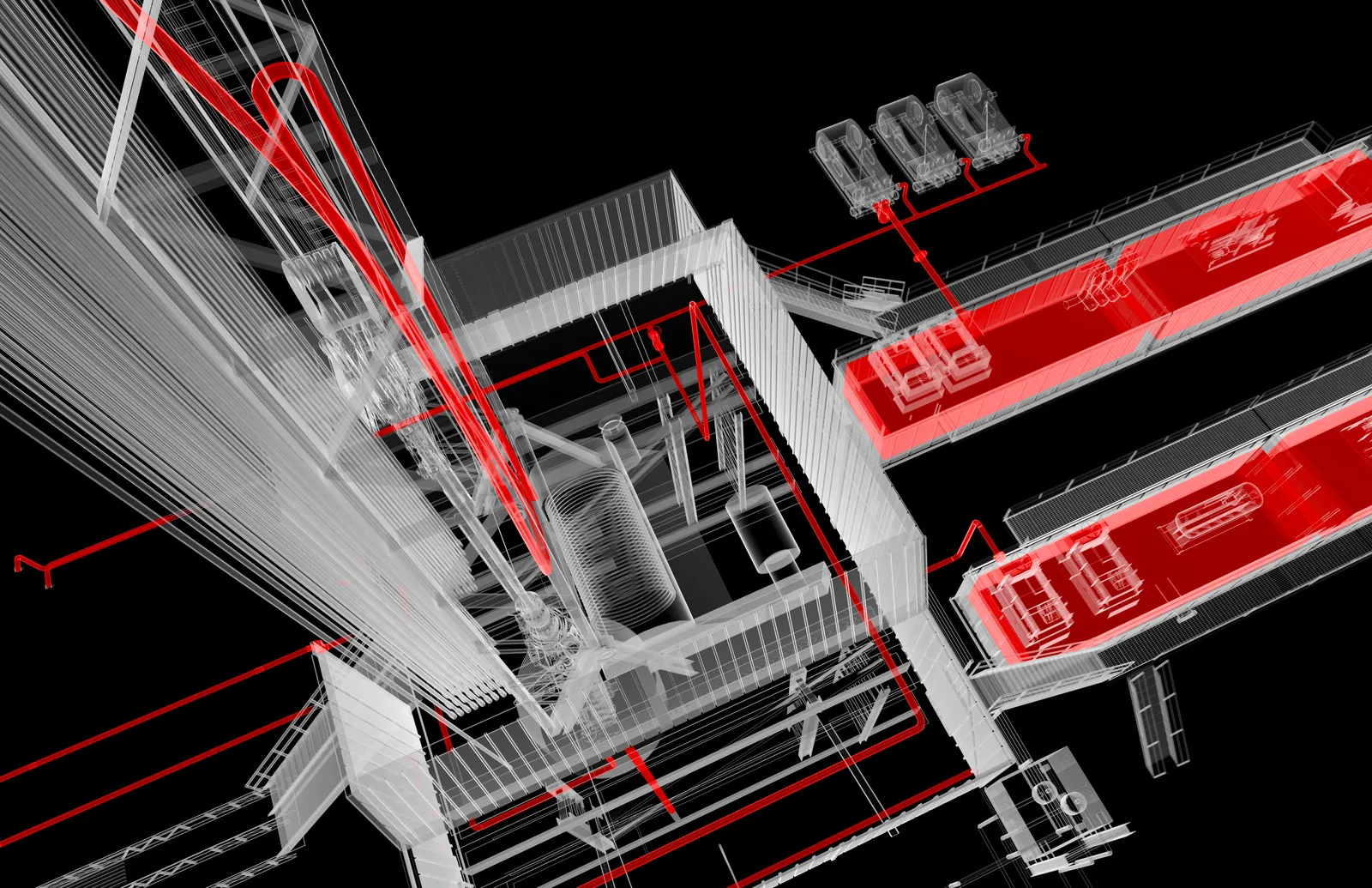

Halliburton Baroid Solids Control solutions help optimize performance, reduce disposal streams, and minimize operational expenses.

Maintaining fluid properties is critical to drilling efficiency, wellbore integrity, and overall performance. Baroid technologies extend fluid life and optimize rates of penetration (ROPs), as well as ensure return of high-quality drilling fluid to the active system.

Our solids control experts can work with you to design a solution to raise flow rates, decrease dilution, and reduce the volume of required additives. The result is smoother processing, less transported waste, and lower cost of operation.

The Bara-G-Force™ hydraulic centrifuge stand allows you to deliver pumps, panels, centrifuges, and more – as a self-lifting, plug-and-play assembly.

01:15

Halliburton Baroid delivers separation solutions that can improve the efficiency of your operations.

Removing drill solids and recovering fluids and weighting agents are effective ways to control fluid performance.

Frequent delivery of freshwater resources to the rigsite can drastically impact the profitability of your wells.

Removing large solids from drilling fluids is critical to maintaining acceptable fluids properties.