Search

Search

Search

Search

Service quality was increased by 50% with respect to certainty of execution.

Download PDFDeepwater

Improve service quality using real-time virtual tracking system

Brazil

The Brazilian oil industry is driven by a major operator in Brazil who continues to lead the digitization process. A key objective there is to invest in advanced digital technologies to optimize operations and engage suppliers in the search for solutions aligned with areas of technological innovation. The focus is on minimizing personnel risk, reducing costs, and enabling faster response times. This approach ensures the safety of individuals, streamlines expenses, and allows for swift decision-making and action when needed.

As part of this strategy, suppliers are positioned as central elements to help ensure competitiveness, security, and future value generation. The operator drives its suppliers to use innovative solutions in Brazil and abroad for testing and validation in real application environments to meet challenges and identify technologies with elevated potential for implementation and value generation.

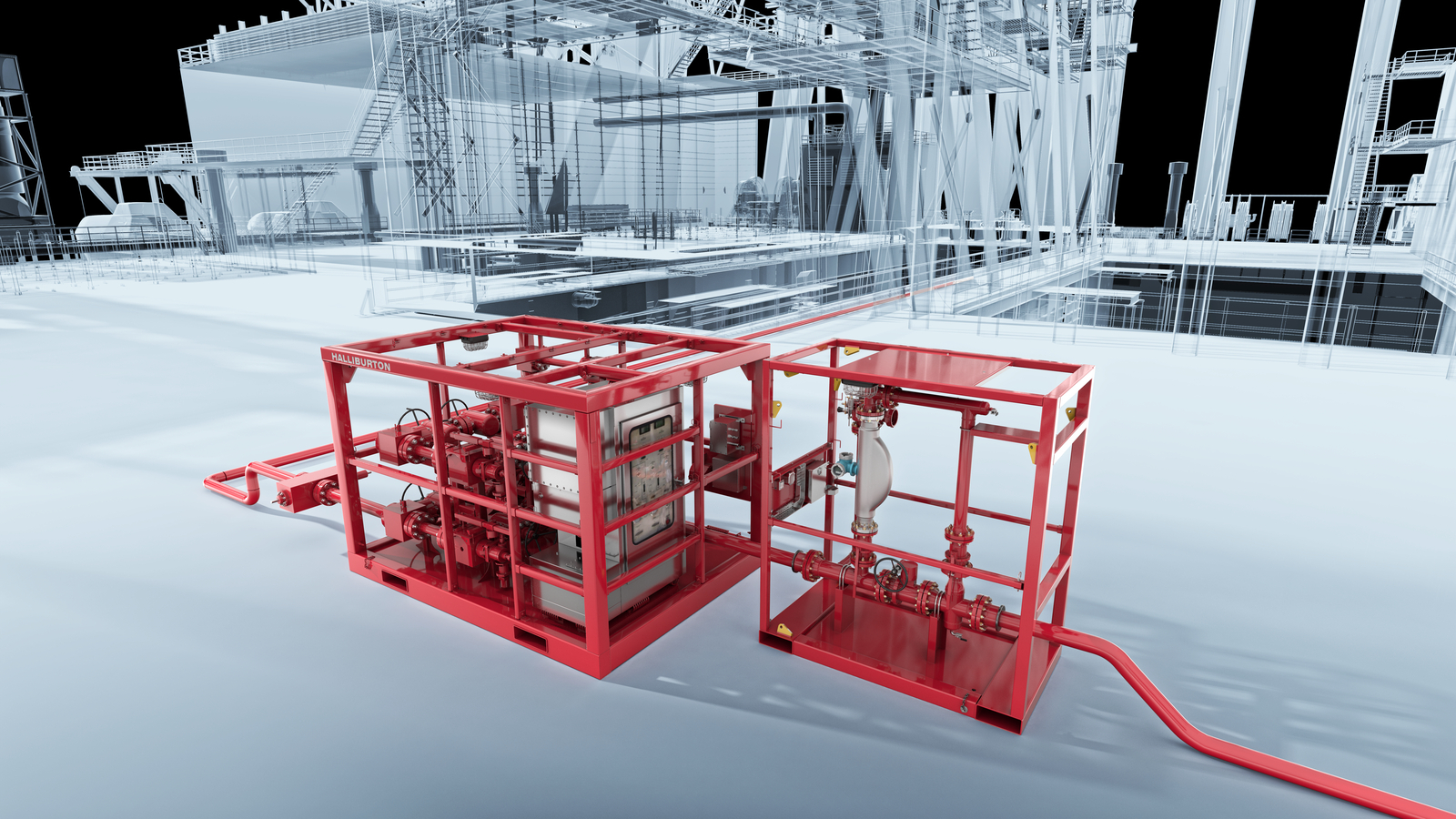

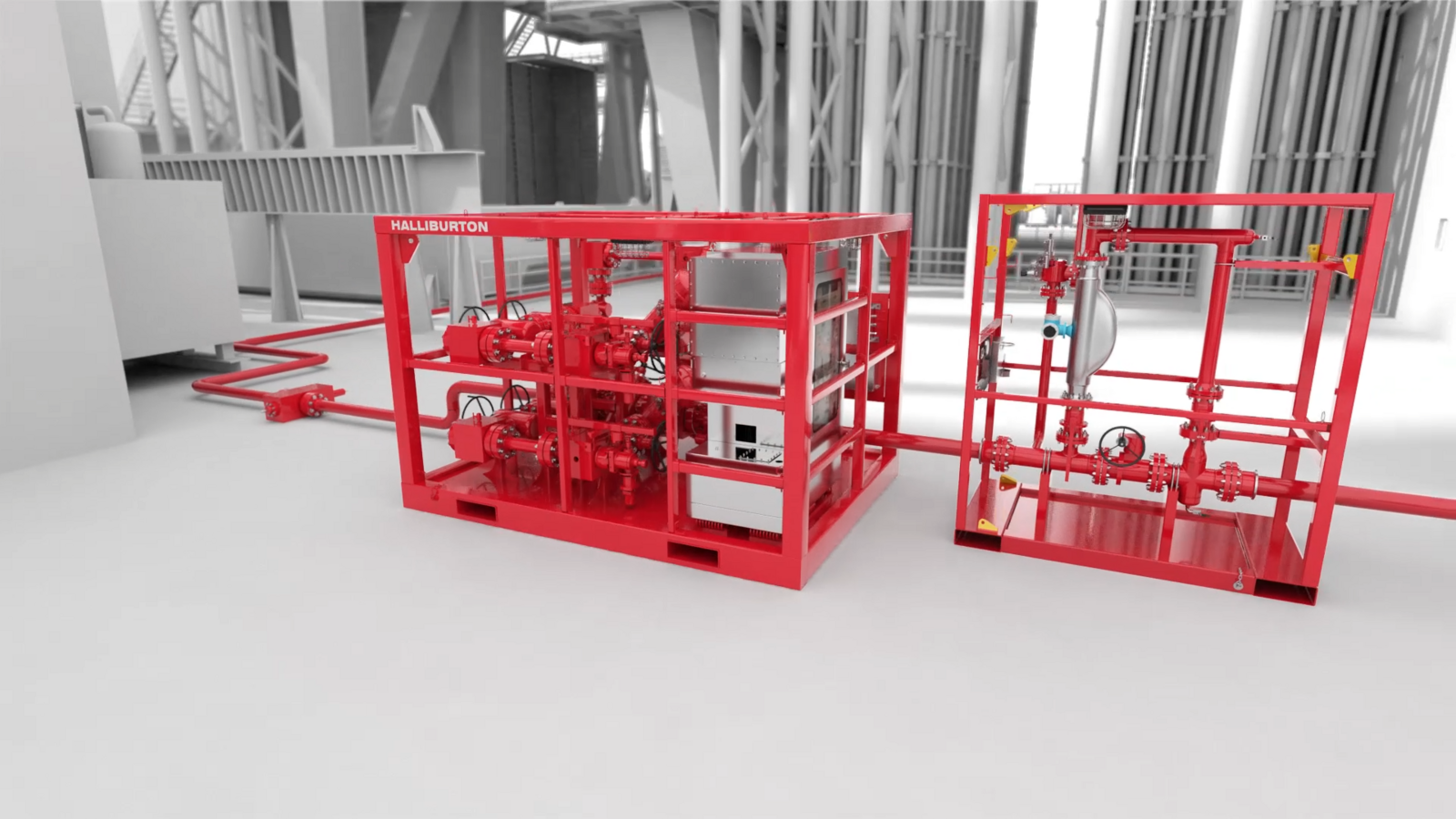

Recently, the operator partnered with Halliburton’s Managed Pressure Services (MPS) team for the first deployment of remote managed pressure drilling (MPD) operations. While this type of operation has been performed previously by competing service providers, Halliburton delivered elevated service quality during critical operational situations.

The operator partnered with Halliburton to implement a real-time operations tracking system for a well in one of its primary deep water projects. This system needed to monitor drilling operations from onshore base stations to help minimize risks associated with the human cognitive factor onboard offshore platforms. This type of technology has been widely used on offshore platforms by this operator in other areas and has proven fundamental to ensuring operational efficiency and personnel safety.

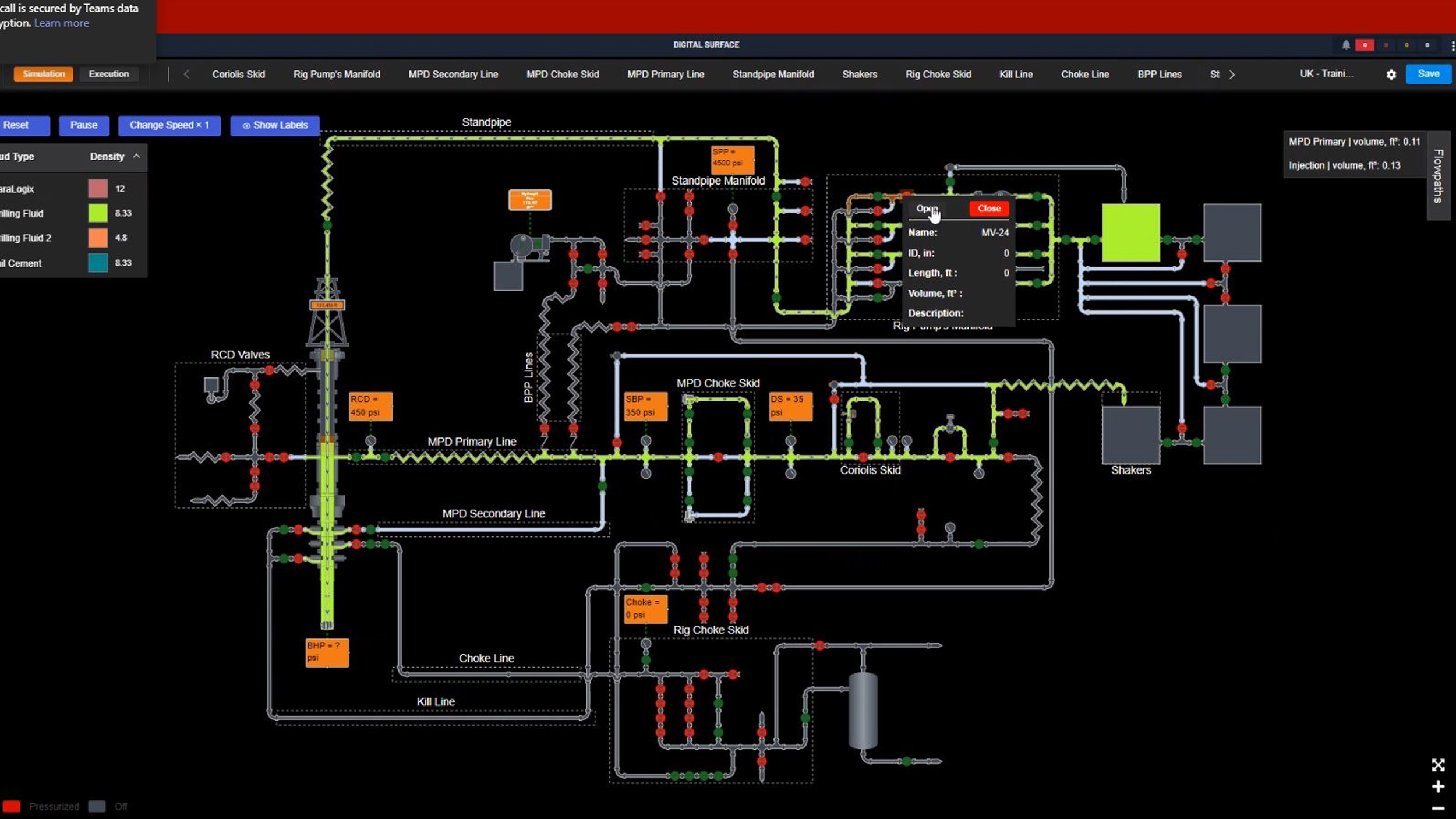

One of the keys to the Halliburton solution is the creation of a digital twin that encompasses the entire control environment – all essential operational data as well as critical control and configuration data – readily accessible in the event of any rig issues or even simulations. The digital twin serves as a valuable tool, providing a virtual representation of the operation onboard and its associated control systems, enabling operators to monitor and manage operations more efficiently and make informed decisions based on real-time data. This ensures comprehensive information is available to effectively address and resolve any potential problems that may arise during the operation, improving operational efficiency and optimizing the overall performance of the well.

Additional aspects of the solution included event recognition through smart alarms, reviewing operational sequences based on well planning meetings focused on applying lessons learned and best practices, following up on cost-optimization initiatives and risk analysis, reviewing software settings critical to MPD operations, intervention of the offshore system in the event of necessary troubleshooting, and improved communication between the operations team and the strategic decision-making team.

During this project, the team encountered various operational situations that required intensified attention, such as dynamic pore pressure testing, severe losses, riser gas, low depletion zones in the middle of the drilling phase, and even drilling/mud rollover guided only by the GBSetPoint™ real-time hydraulics model because of PWD tool failure. Each of these situations were successfully addressed.

Overall, service quality was increased by 50% with respect to execution certainty. Halliburton’s solution increased the confidence and focus of onboard operators, generating value to the operator with respect to accurate decision-making, ultimately aiding the continuous improvement process in terms of safety, performance, and cost.

Also, because this type of service will be required on future projects, this effort helped Halliburton adapt to the operator’s future remote operations needs.

Navigate challenging pressure windows between pore and fracture pressure in complex wells to reduce drilling days and NPT.

Managed pressure drilling (MPD) is an enabling technology that can accomplish efficiency goals while mitigating drilling risks.