Search

Search

Search

Search

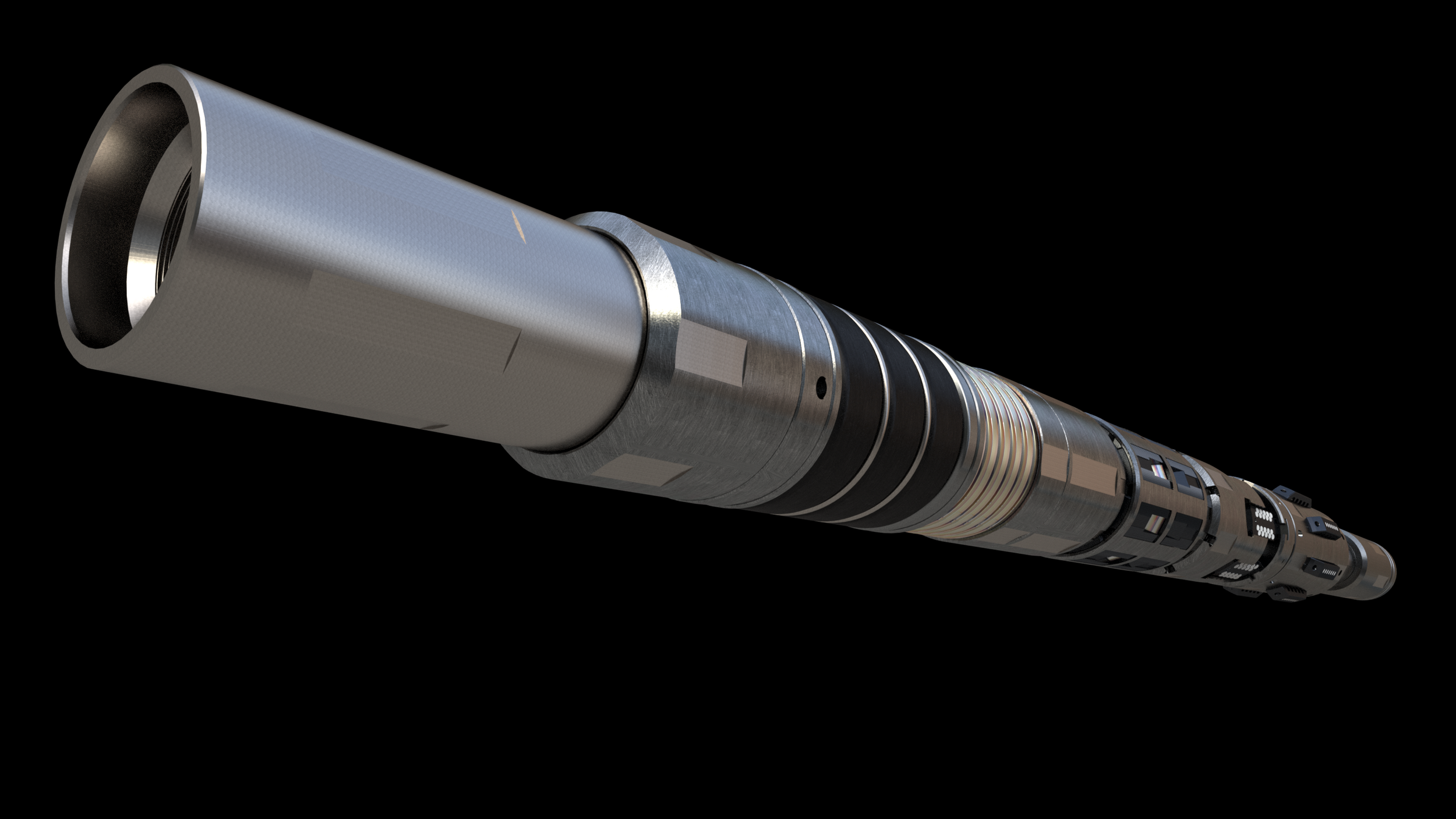

Temporary well suspension using 9 5/8-inch Intercept® retrievable bridge plug provides API 11D1 V0 well barriers for subsea bop removal

Download PDFEstablish API 11D1 V0 barriers to allow for drilling BOP removal from a subsea

United Kingdom

During a subsea development project, the operator planned a temporary well suspension, which required dual retrievable bridge plugs acting as API 11D1 V0 barriers to help ensure safe removal of the drilling BOP before installing the subsea Christmas tree.

To save time and cost, the operator also wanted the ability to run, set and test the retrievable bridge plugs, without running and subsequently leaving additional drillpipe hung below the plugs.

Halliburton Intercept® retrievable bridge plugs provided the ideal solution to meet the operator’s objectives. This marked the first deployment of the 9 5/8-inch Intercept retrievable bridge plug in the UK.

Due to the nature of the well, the operator required retrievable bridge plugs qualified to API 11D1 V0 standards to help ensure safe and secure well suspension during drilling BOP removal from the wellhead and subsea tree installation and testing.

In addition, the operator wanted retrievable bridge plugs that could be run on drillpipe, set and tested from above and below, without deploying drillpipe below each plug. This ability would help reduce cost, time and risk during the operation.

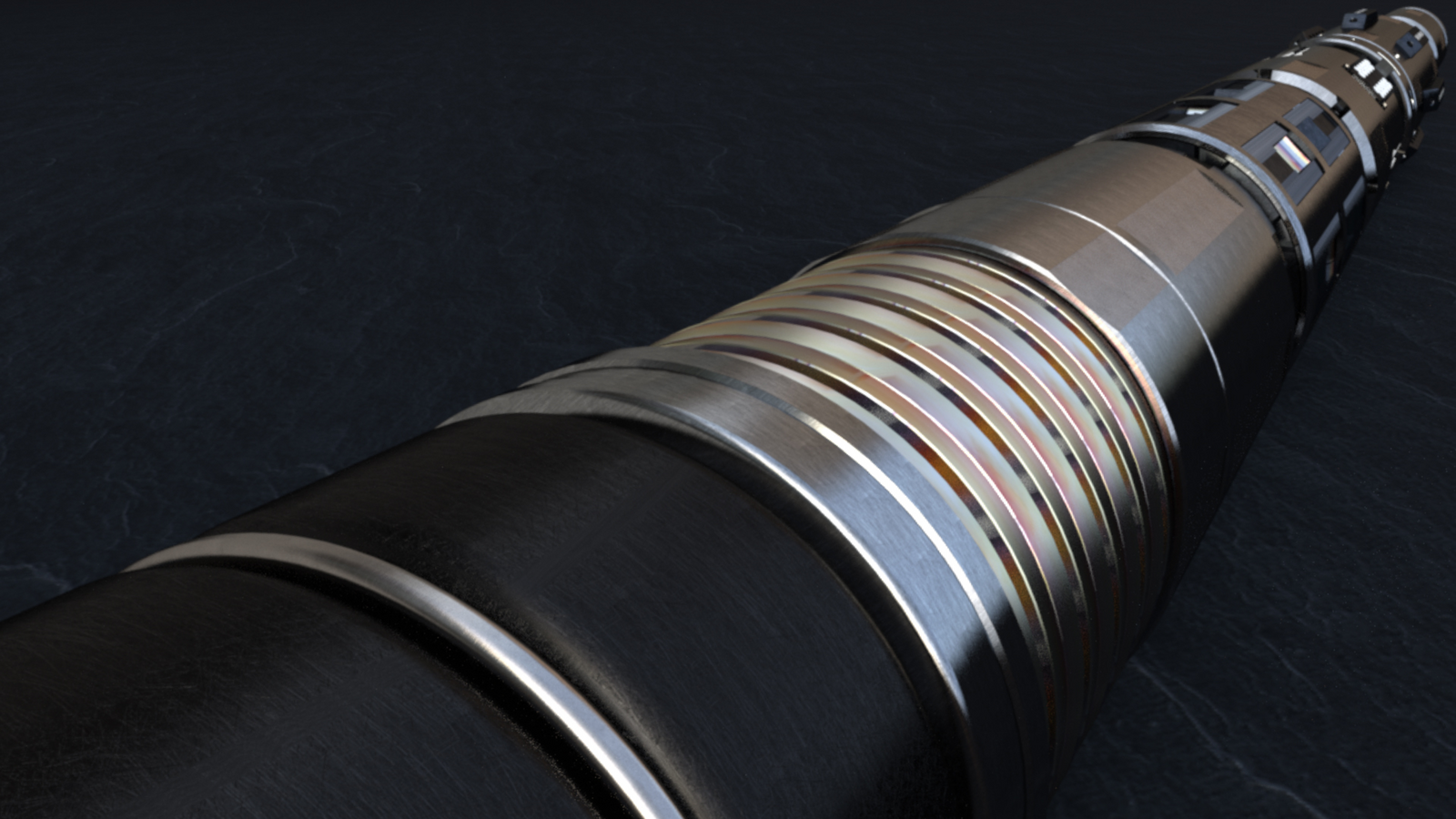

Halliburton provided 9 5/8-inch Intercept retrievable bridge plugs, which delivered the API 11D1 V0 barriers required to temporarily suspend the well while also removing the hang-weight requirement below each plug. The Halliburton team collaborated with the operator and developed a detailed job plan to ensure safety and service quality throughout operations.

A Halliburton service specialist successfully deployed and set the plugs at 2,037 and 1,662 feet, respectively, without issues. The bridge plug design enabled testing from above and below to 4,500 psi confirming the integrity of the plugs before removing the drilling BOP. After nippling down the BOP and installing the subsea tree, the barriers enabled testing of the subsea tree prior to successful recovery of each retrievable bridge plug to continue drilling operations.

use of the Intercept retrievable bridge plug in UK

psi set above and below

ft depth for setting plugs

The first-time use of the Intercept® retrievable bridge plug in the UK exceeded the operator’s expectations, providing reliable API 11D1 V0 barriers and delivering key cost and time savings to maximize asset value. Eliminating the need to run drillpipe below each bridge plug also reduced operational risk and helped improve efficiency. In addition, the ability to monitor the well and confirm well pressures below the plug prior to retrieval helped ensure safe operations.

Halliburton safely deployed and recovered each bridge plug on the first attempt, even with substantial debris within the wellbore.

Data Sheet

Suspending the well and keeping it stable and safe are especially critical when performing activities such as:

Intercept® Retrievable Bridge Plug is a gas-tight, well suspension barrier adopting quick and easy operating procedures

Halliburton drillable squeeze packers and bridge plugs offer enhanced reliability, reduced rig time, and quick drill out.