Search

Search

Search

Search

Maximize production efficiency and improve steam-oil-ratio in SAGD wells

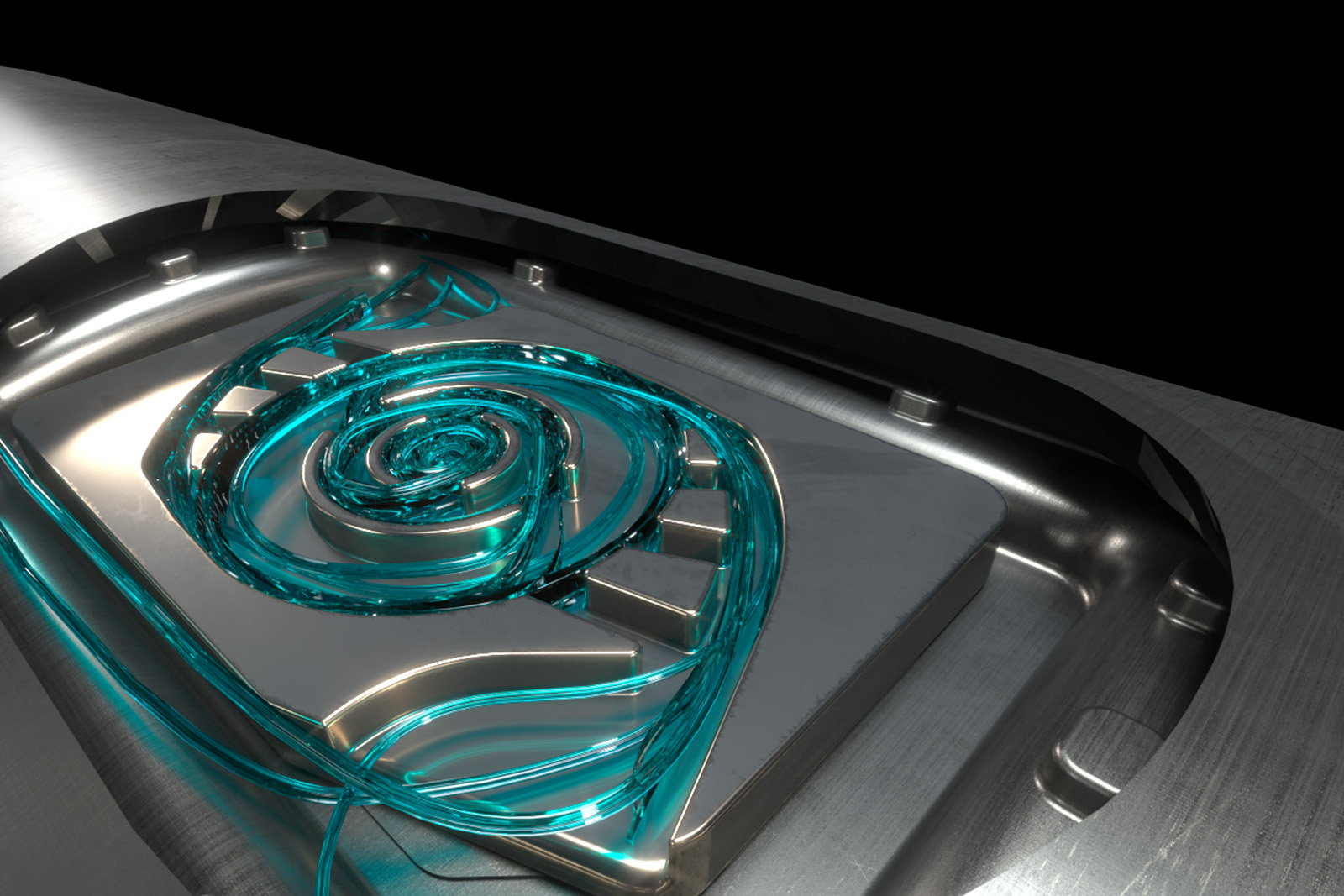

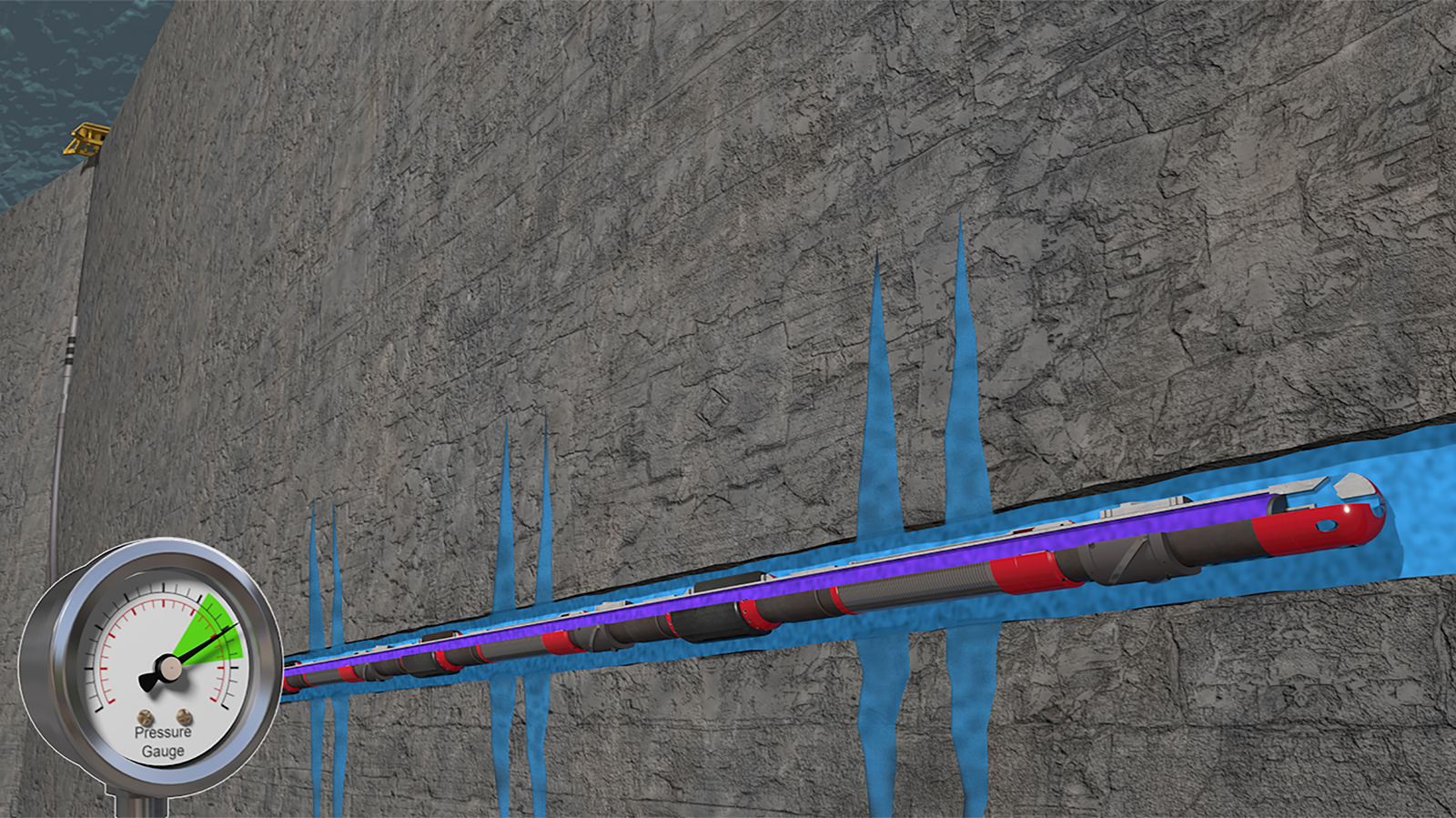

Talk to an expertHalliburton’s EquiFlow OptiSteam flow control device (FCD) helps improve completion performance and efficiency in steam-assisted gravity drainage (SAGD) operations by balancing steam injection throughout the length of a completion.

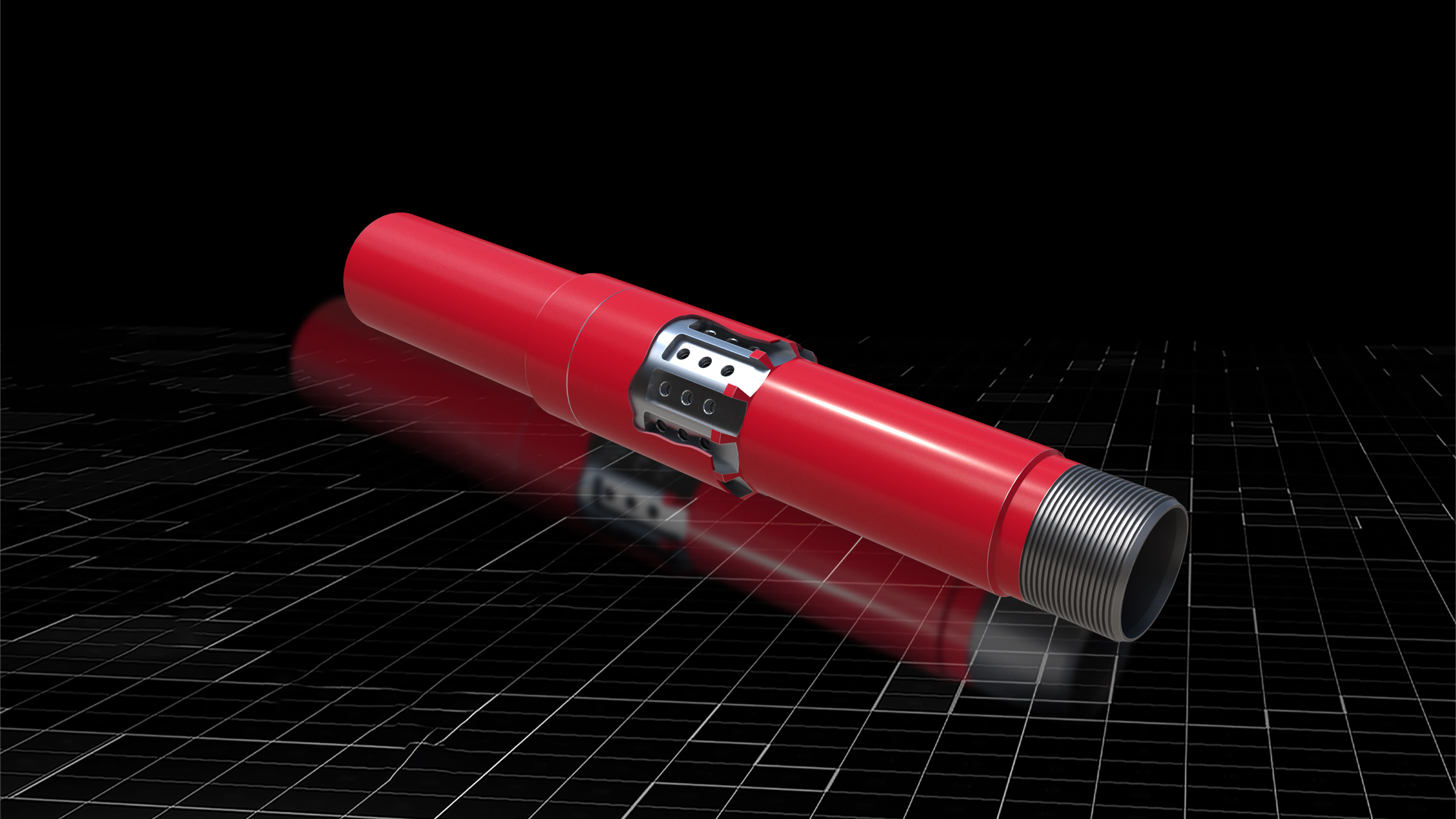

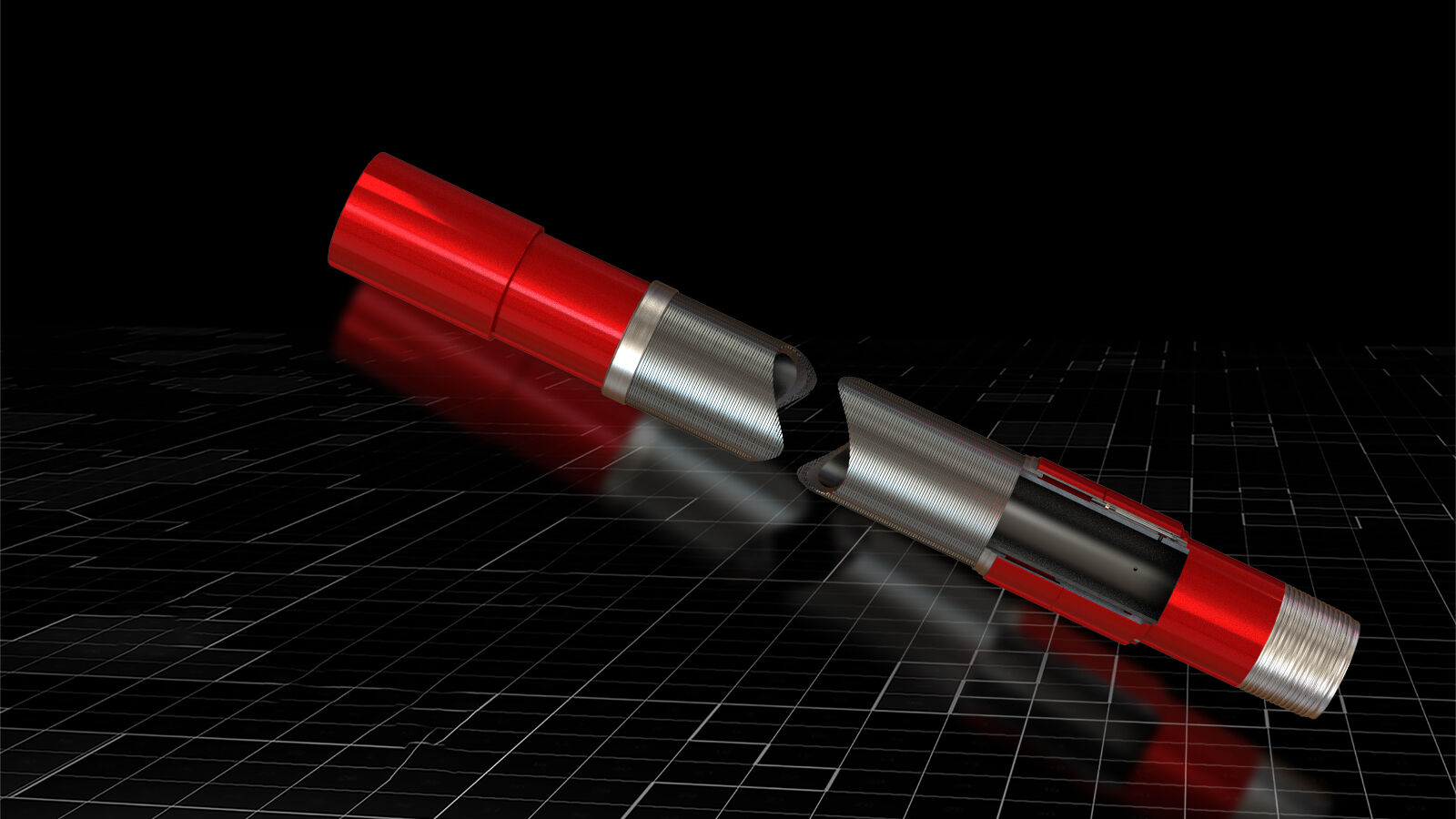

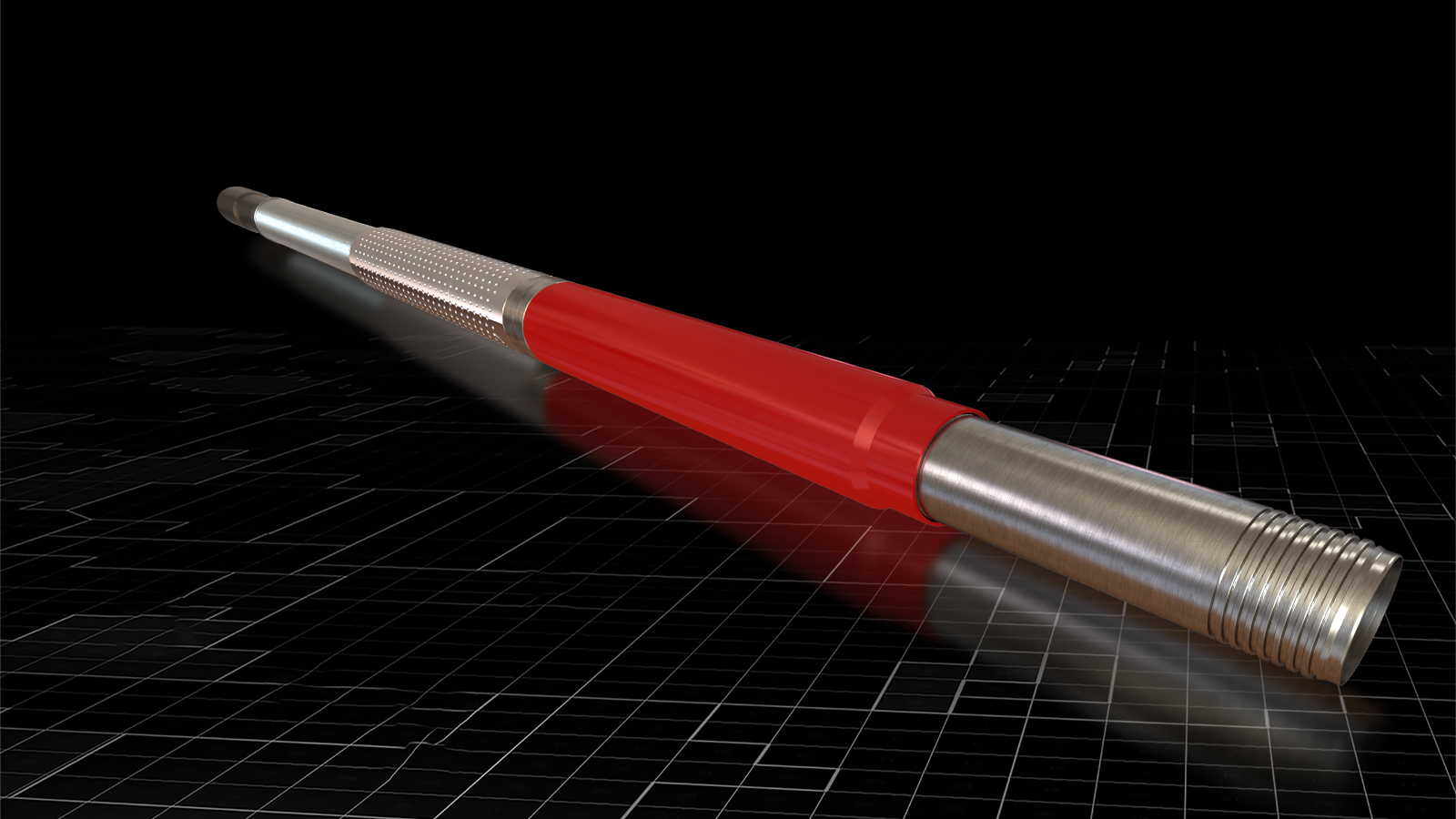

The EquiFlow OptiSteam FCD consists of four components – a top sub, bottom sub, sleeve, and a center nipple with two sets of flow ports. Injected steam travels through the tubing and controlled ports, into the tubing-liner annulus, and finally through the liner into the formation.

The sleeve is an optional component which provides the operator ON/OFF ability. This allows flexibility to be run closed, circulate steam during warm-up, then shift open for injection. Also, if one zone becomes too hot, the device can be shifted closed. A common B-type shifting profile is used.

Halliburton’s suite of flow control devices for SAGD wells offers solutions to maximize production efficiency and help operators improve steam-oil ratio (SOR). Together the EquiFlow inflow control device (ICD) and autonomous ICD help optimize steam flow in SAGD production wells.

Balances production flow and restricts unwanted production fluid, even with minimal viscosity difference between the produced fluids.

Helps delay and reduce the flow of unwanted fluid and stimulates balanced production throughout the entire interval.

Combines the benefits of inflow balancing with the flexibility to reconfigure the ICD as needed.

The EquiFlow ICD with sliding sleeve combined with the PetroGuard® sand screen provide inflow control technology with a mechanical sliding sleeve functionality.

Increasing oil recovery at lower cost with washpipe-free ICD completions.

With SAGD injectors, steam must be balanced to account for varying payzone thickness, reservoir heterogeneity, and heel-toe tubing frictional effects. An optimized steam chamber allows for maximized bitumen recovery versus the traditional dual tubing injection method, which cannot properly balance the steam chamber and often develops a ‘barbell’ chamber instead. The EquiFlow OptiSteam FCD provides the proper outflow balance.