Search

Search

Search

Search

Reliable, real-time monitoring of downhole conditions

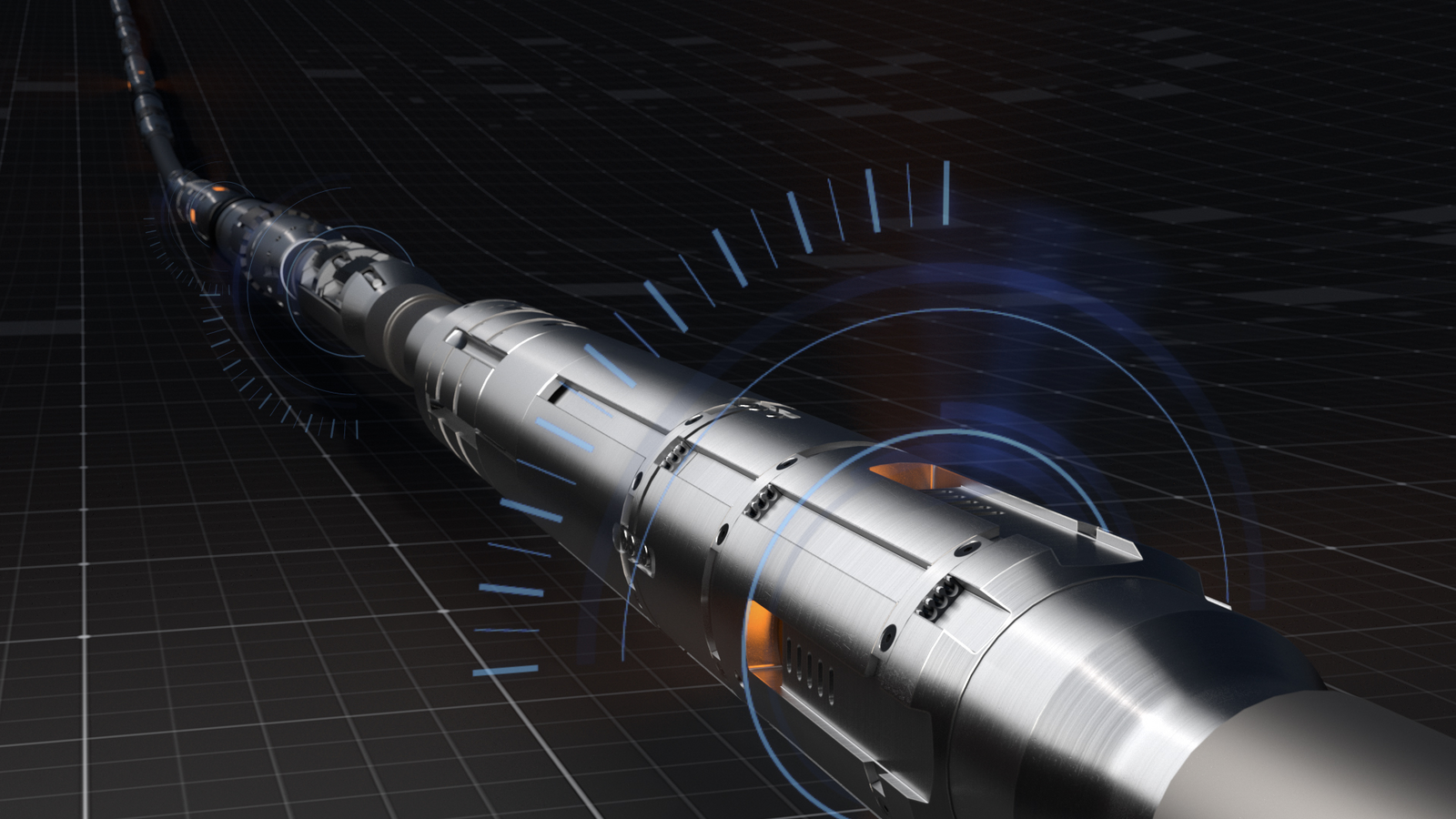

Talk to an expertIn today’s challenging environments, there is an increasing need for reliable and accurate reservoir data, driving the need for continuous improvement of monitoring technology. Opsis permanent downhole gauges are the latest addition to the DataSphere® permanent monitoring suite, providing real-time downhole data for increased productivity throughout the life of the well.

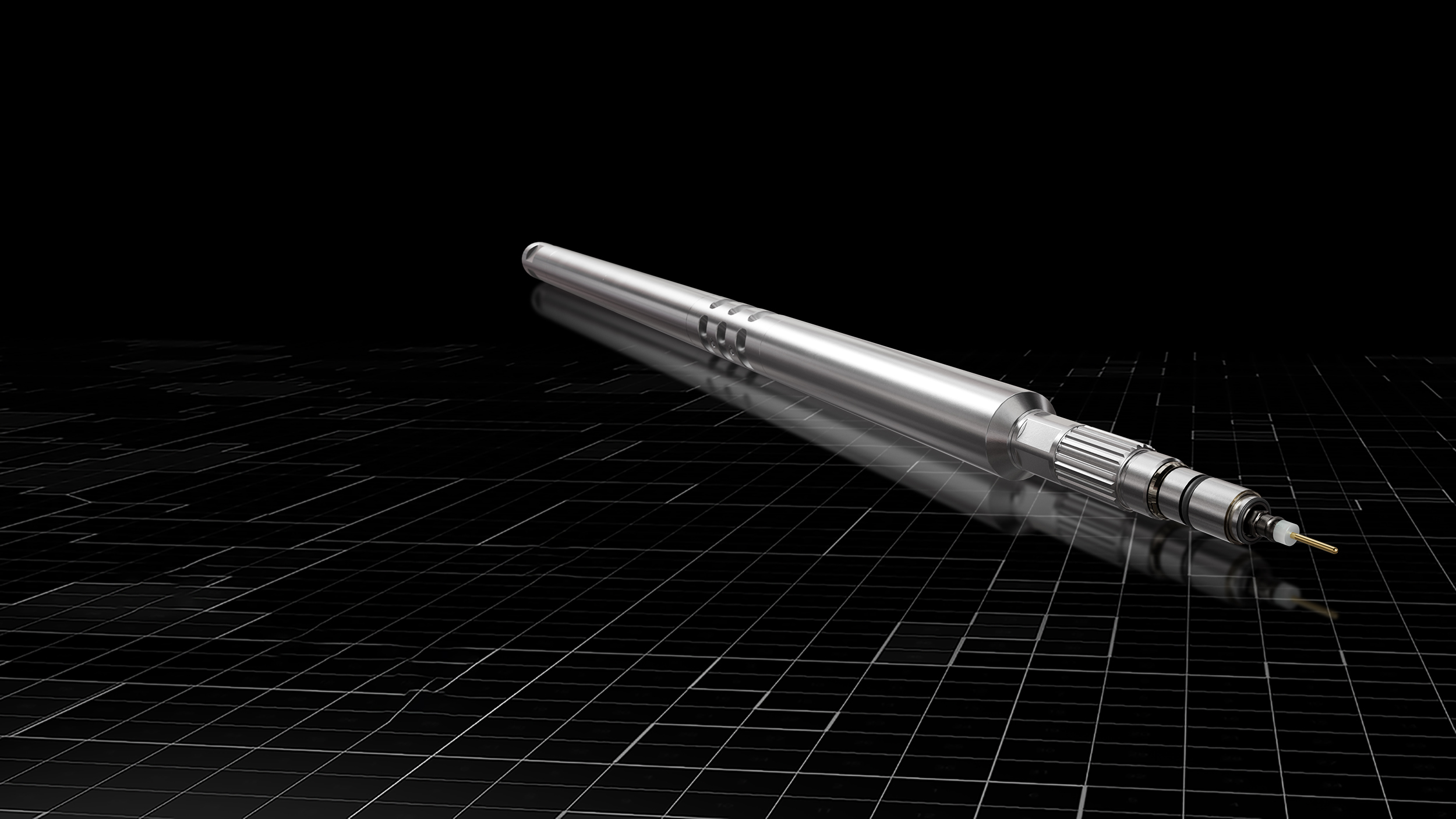

Opsis gauges feature ASIC (Application Specific Integrated Circuit) technology in combination with field-proven resonating quartz crystal sensors. The result is highly accurate pressure and temperature measurements, even under extreme temperature conditions.

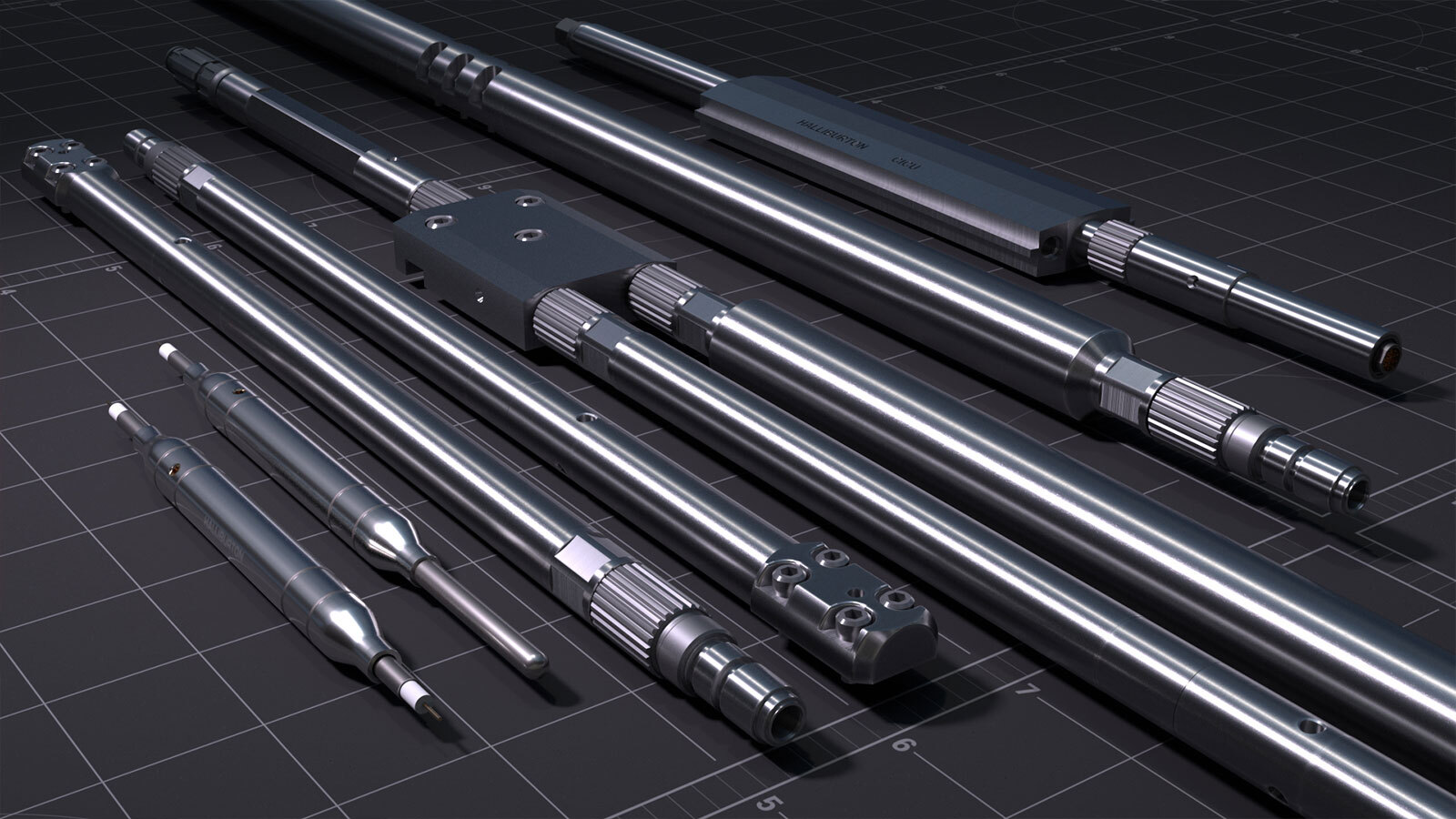

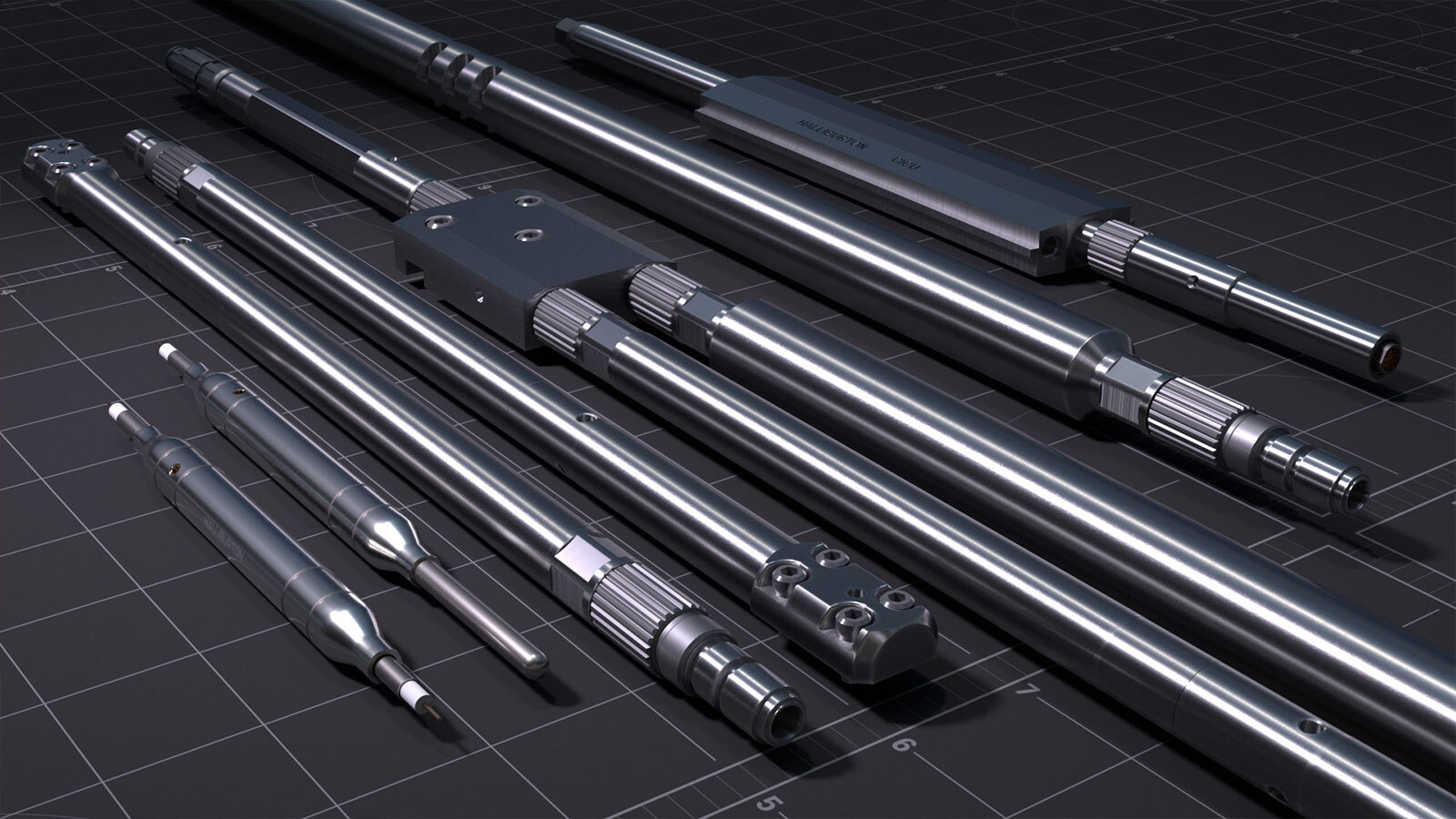

Opsis gauges can be used for single or multi-zone monitoring applications. These gauges may be ported to tubing, annulus, or control line. The addition of feed-through or splitter block assemblies enables the monitoring of multiple zones.

Opsis gauges use a high performance cable termination with a sealing arrangement based on our highly reliable intelligent completion FMJ connector. This cable termination incorporates a pressure-testable dual metal-to-metal ferrule seal arrangement for isolating the downhole cable outer metal sheath from the well fluid.

Opsis gauges are tested to the full pressure and temperature rating during Factory Acceptance Testing (FAT), and each gauge comes with an independently checked calibration certificate.

New gauge designs are subjected to Reliability Demonstration Testing (RDT) per AWES Recommended Practices.

Halliburton SmartWell completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data while also controlling and monitoring selected reservoir zones remotely and in real-time.

The DataSphere permanent monitoring suite is a robust combination of the best in sand control, multilateral and intelligent completion technology