Search

Search

Search

Search

Reduce operational risks and cost associated with production logging runs

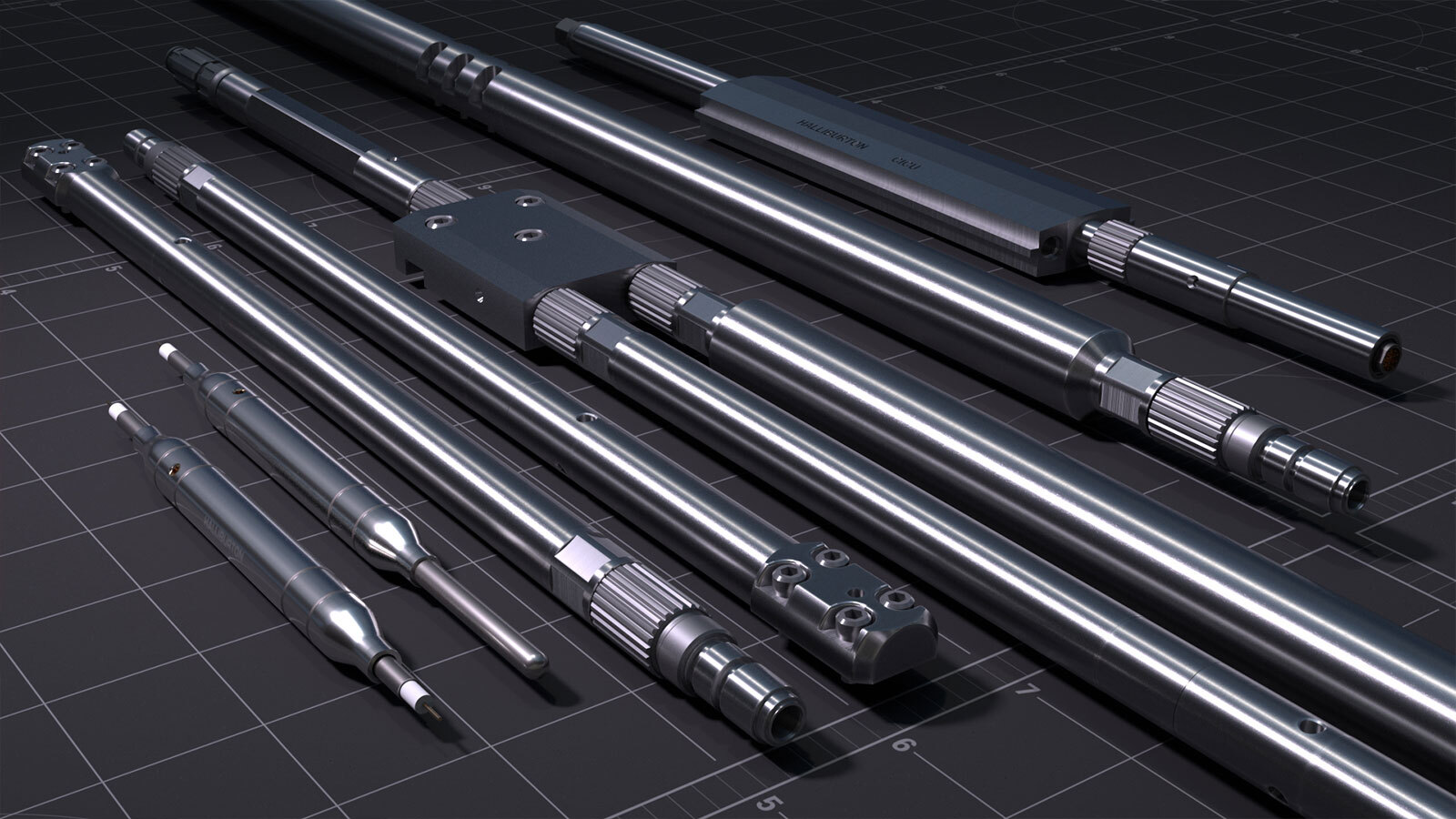

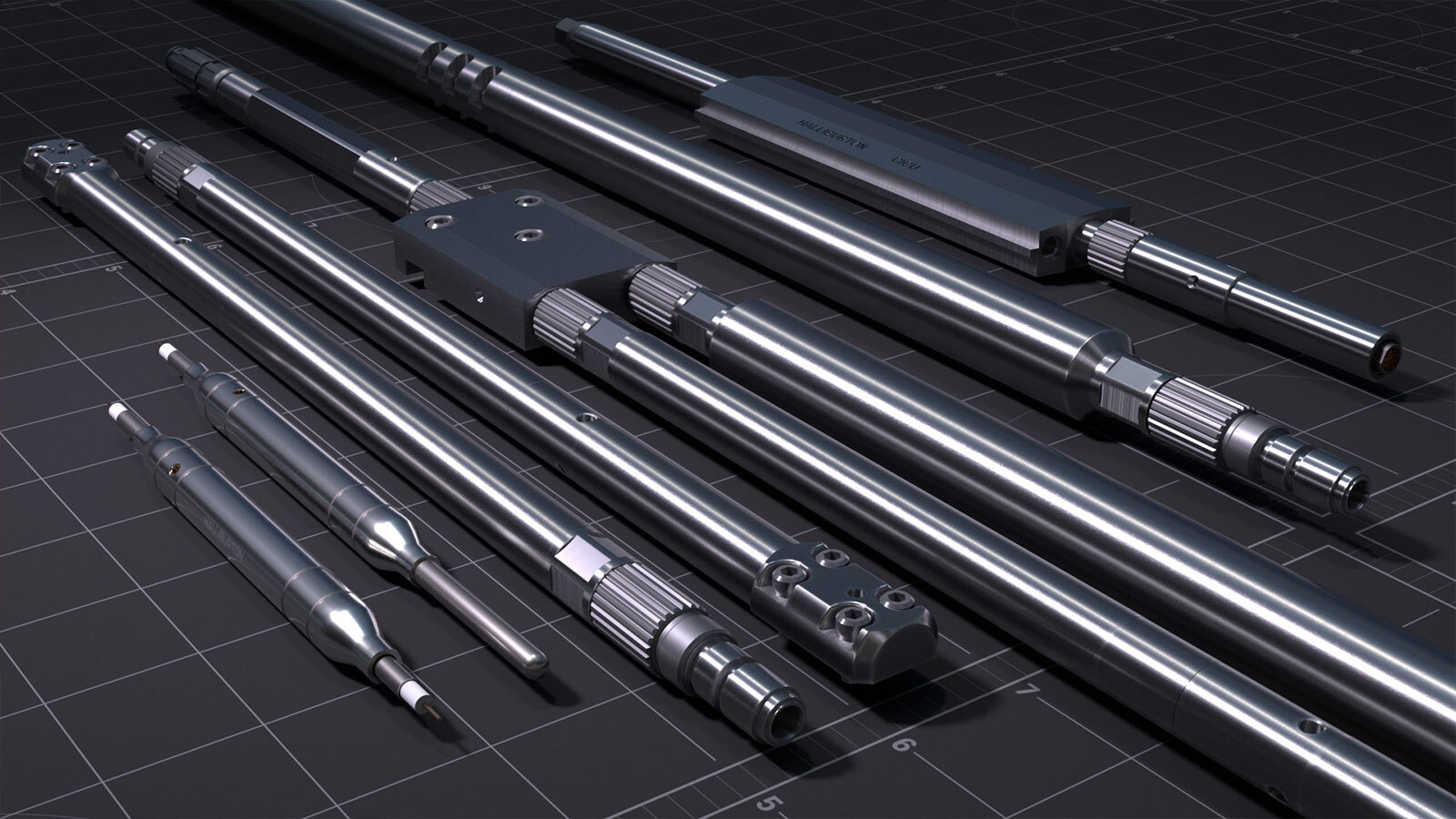

Talk to an expertHalliburton’s FloStream™ flowmeter is a Venturi design that can handle a variety of production rates and fluid properties and is designed specifically to meet the requirements of the well. Utilizing a FloStream flowmeter reduces operational risk and cost associated with production logging runs later in the life of the well.

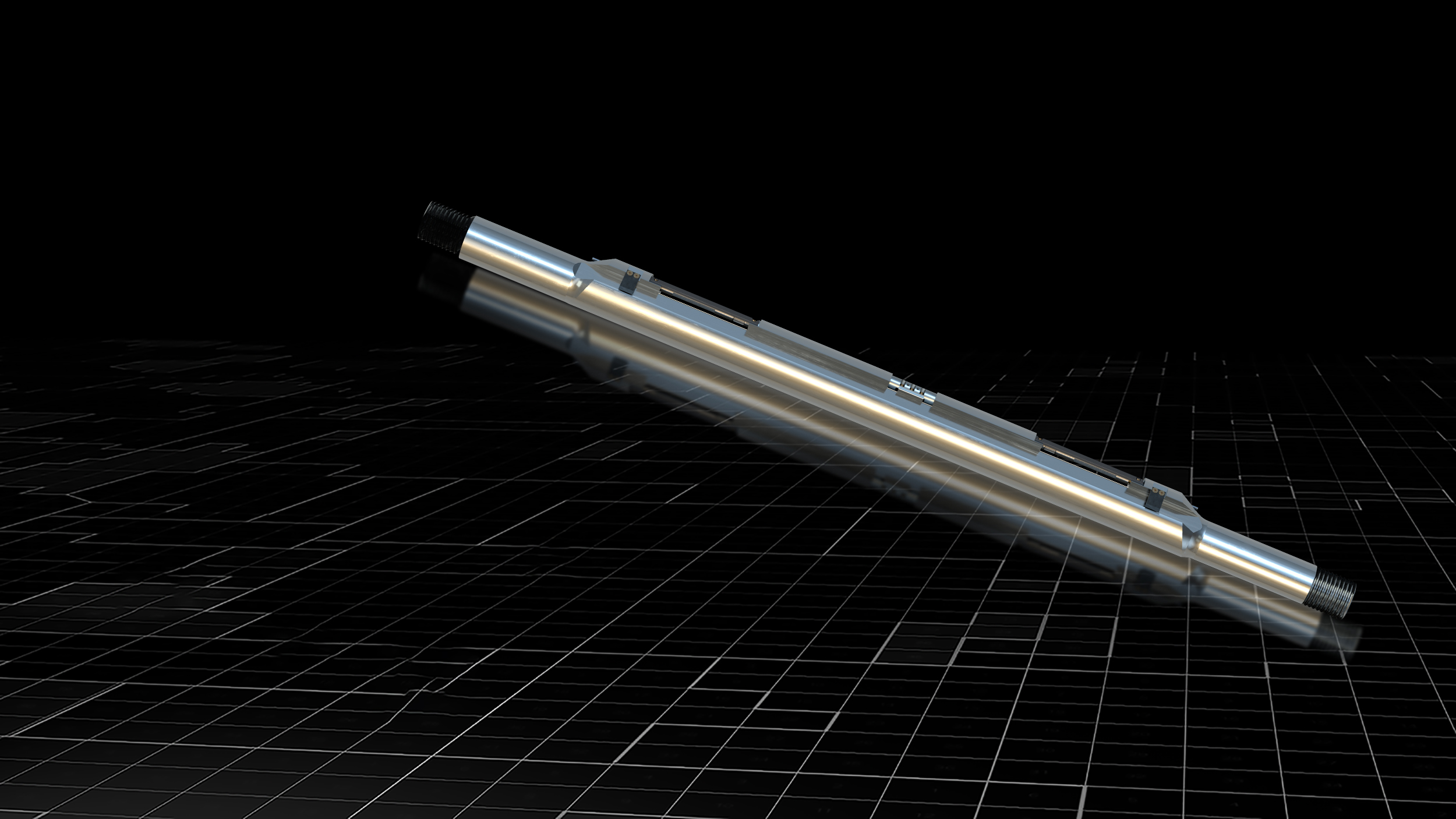

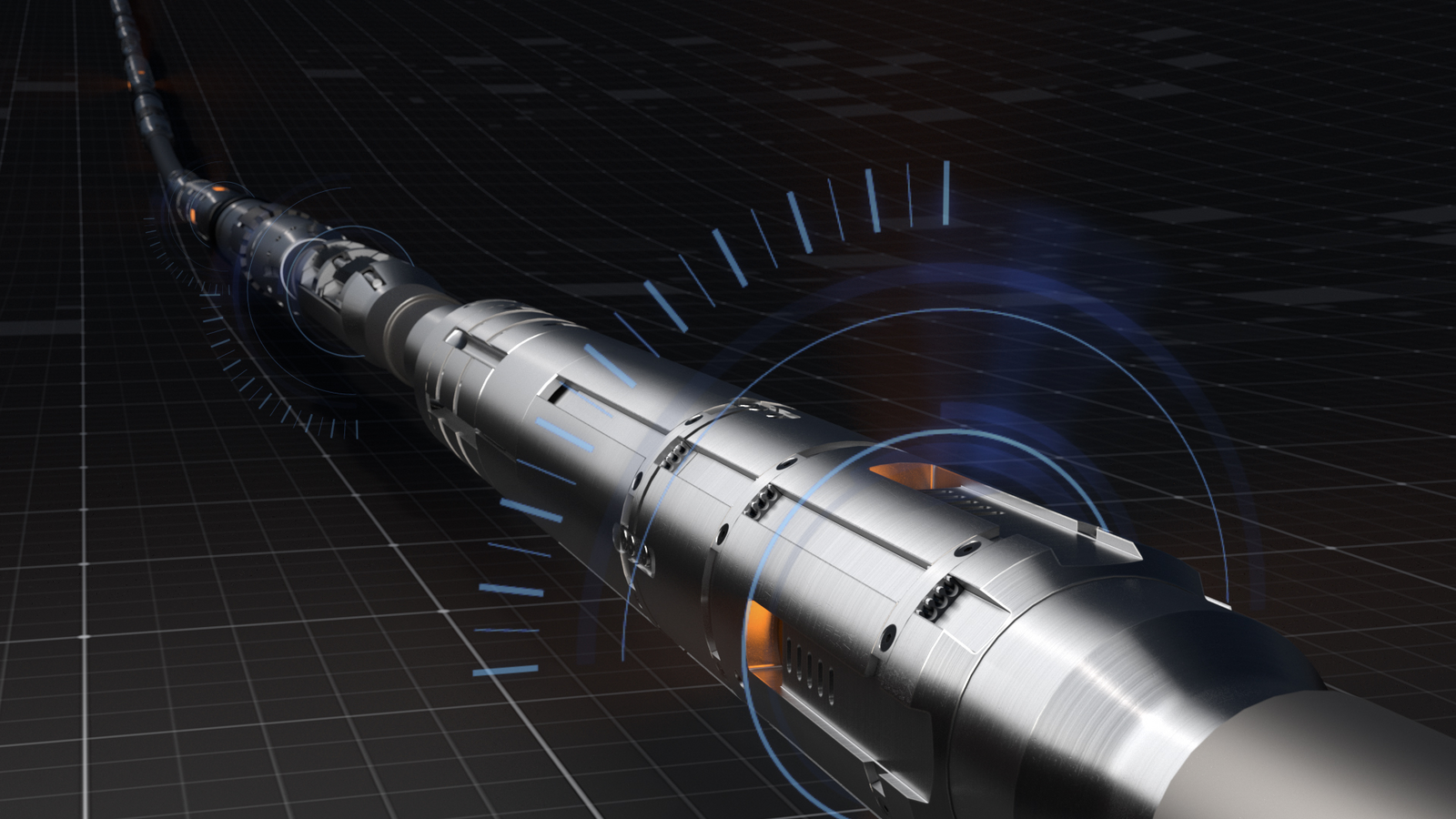

The Venturi device consists of a conical, convergent inlet connected to a cylindrical restriction (called the “throat”) and a divergent conical section, which allows the pressure drop to be recovered. The FloStream flowmeter employs two Opsis® high accuracy quartz permanent downhole gauge (PDG) sensors to measure absolute pressures at the Venturi inlet and the throat. When flow occurs through the Venturi, there is a drop in pressure between the inlet and the throat sections. The calculated pressure drop can then be converted to mass flow rate.

The FloStream flowmeter uses the same modular design as other Halliburton gauge mandrels with identical gauges, mounting arrangements and terminations. The downhole cable, cable protectors, connectors, and subsea control system interface for the flowmeter is also the same as for standard gauge systems. The time required and run-in-hole procedures for both systems are also identical.

An accuracy of ±0.6% has been demonstrated when the flowmeter is operating under the design conditions. Even when these change, an accuracy of ±2.5% is achievable, provided the limits of the Venturi principle are not exceeded. Resolution in flow rate measurement is ±0.25%

The Venturi flowmeter mandrel incorporates a wireline-retrievable Venturi section which allows for changing of the Venturi should the flow rate change significantly or removal of the restriction should it become necessary to carry out well maintenance operation below the flowmeter.

Halliburton SmartWell completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data while also controlling and monitoring selected reservoir zones remotely and in real-time.

The DataSphere permanent monitoring suite is a robust combination of the best in sand control, multilateral and intelligent completion technology