Search

Search

Search

Search

Stimulation chemicals that help prevent well souring and contamination by eliminating sulfate-reducing and acid-producing bacteria

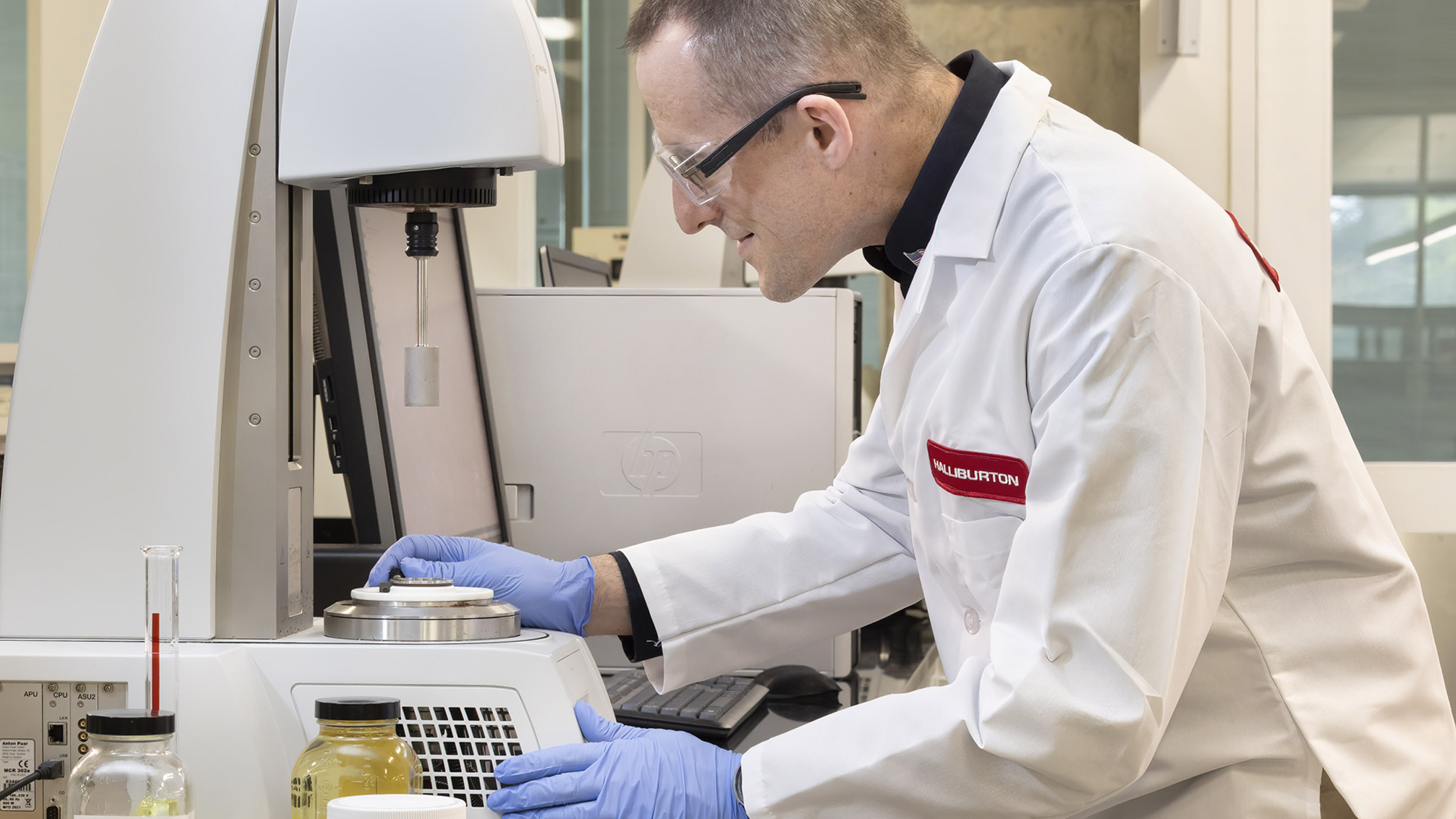

Talk to an ExpertDuring a fracturing treatment, bacteria can be introduced into the well from both the water and sand being pumped. This is where biocides come into play: to control bacterial growth and ensure asset integrity.

Untreated bacteria can result in microbial growth, leading to well-souring, iron sulfide formation, and corrosion. Each of these can threaten the production of your assets and lead to costly remedial operations or potentially well abandonment. Halliburton bacteria control solutions optimize stimulation treatments by helping to prevent well souring and contamination.

Bacteria Control

Halliburton technical experts can help determine the right combination of biocides needed to effectively kill and control bacteria from the start of the frac through production. The Multi-Cide® biocide service helps prevent well souring and contamination by eliminating bacteria for safe, cost-effective, and high-performance fracture stimulation.

Discover Multi-CideBacteria control in oil and gas operations can be difficult due to high temperatures and high salinity associated with the reservoir. Oxidizers are typically used for quick kills. The drawback to this option is that it leads to incompatibility issues with the frac fluid and frac equipment. Other options, such as chlorine dioxide (ClO2), peracetic acid (PAA), and peroxide are known to affect friction reducer performance and can lead to corrosion of frac equipment, such as accelerated pitting. Additionally, using these oxidizers requires large equipment on-site and additional HSE risks.

Halliburton's biocide programs are much more modular, straightforward, and precise. Our bacteria control solutions provide low-dose, on-the-fly metering of products, utilizing specialized pumping equipment and Halliburton personnel to determine the most effective biocide program. We also conduct interim bacteria testing during a job to ensure efficient product delivery and performance.

We provide optimized biocide treatments based on advanced testing. Our bacteria control programs provide a multi-component application consisting of a combination of either a quick kill and/or preservative, which are tailored to your assets, challenges, and key performance indicators. This biocide treatment coupled with Halliburton’s stimulation chemical expertise and equipment helps maximize operational efficiency.

Scale Inhibitors

The Scalechek® scale prevention service effectively inhibits the formation of sulfate- and carbonate-based scales. In addition to providing excellent control of barite scales in the presence of iron, it performs effectively at low concentrations, in high salt concentrations, in cold weather, and at high temperatures.

Discover Scalechek

A biocide service that helps prevent well souring and contamination by eliminating sulfate-reducing and acid-producing bacteria.

Explore