Search

Search

Search

Search

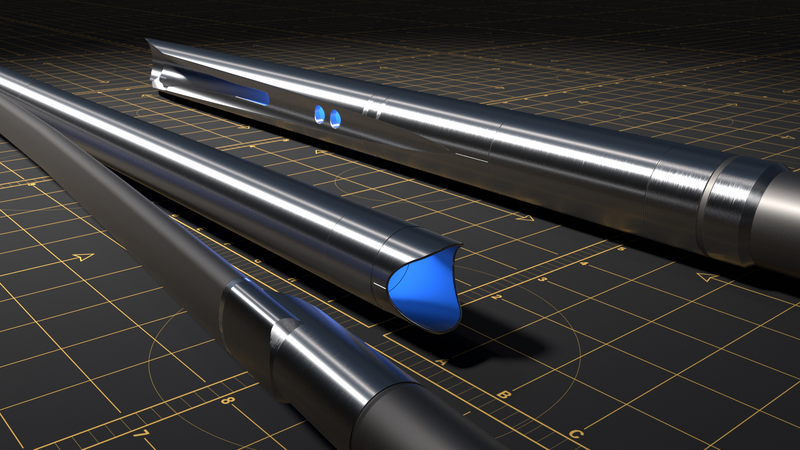

Flexrite® system portfolio provides a reliable and economical solution to meet the needs of evolving deepwater applications

Download PDFDeep Water

Increase total drainage area from an existing subsea template structure

North Sea

Halliburton developed and installed the first FlexRite multilateral completion system in 2001. Two decades later, more than 300 FlexRite multilateral system junctions have been installed in deepwater North Sea wells.

Over this history, the deepwater applications where FlexRite system junctions have been installed have evolved from dual-laterals with standalone screens and commingled flow to tri-lateral intelligent completions as the common multilateral completion strategy in the North Sea.

Many deepwater oil plays in the North Sea were originally deemed uneconomical due to the limited technology available to address the associated challenges. Horizontal and eventually multilateral applications were introduced to address this challenge. In 2001, Halliburton installed the first deepwater TAML Level 5 junction in the region, introducing the FlexRite system.

The first FlexRite system application was a dual-lateral well with commingled production. Total reservoir exposure dramatically increased when compared to the single-bore wells traditionally utilized as the field development strategy. The result was an increase in production, reduced CAPEX and time to production, as well as significant operational efficiency gains over previously installed TAML Level 4 junctions. The average installation time was reduced from more than 15 days to 3 days. The development of the FlexRite system allowed operators to increase production driving further adoption of multilateral technology.

The merit in greater drainage area and increased production in the shortest amount of time was soon thereafter identified. In 2002, the FlexRite system helped enable drilling and completion of the world’s first TAML Level 5 tri-lateral well. Besides increasing the well’s reservoir exposure, tri-laterals reduced drawdown, delaying gas breakthrough and further increasing well production performance. In 2004, these results were extended to the world’s first TAML Level 5 quad-lateral well.

With the benefit of multilateral wells over horizontal wells in deepwater North Sea established, existing horizontal wells in the region needed to be addressed. Limited subsea infrastructure and increasing environmental constraints in the region exacerbated the challenge. Operators needed the ability to retrofit existing productive horizontal wells with multilateral systems or re-enter nonproductive wells to redrill and complete as multilaterals. Halliburton developed the ReFlexRite® system for precisely this purpose. The first ReFlexRite system retrofit installation, in 2005, converted a producing deepwater horizontal well into a dual-lateral well while maintaining the production of the original wellbore. Since this first successful ReFlexRite system installation, Halliburton has completed more than 30 similar junction constructions as either retrofit or re-entry laterals in deepwater North Sea. These and future wells allow for slot recovery and infill drilling.

Gas cap exposure and potential subsequent loss of overbalance and gas influx present challenges to multilateral re-entry operations. The ReFlexRite system is frequently used to mill windows and install junctions inside a section of expandable casing. The ReFlexRite system, in conjunction with expandable casing, helps isolate the gas cap. Using this installation method, well control can be maintained during multilateral re-entry applications. Halliburton performed the first of these installations in North Sea deepwater in 2019.

By 2005, multilateral wells were common in the North Sea, but production was hampered by fluid mobility challenges. Production was distributed relatively evenly from each lateral branch but was sensitive to drawdown at the heel. Oil recovery needed to be improved and gas-coning prevented. The advent of interval control valves (ICVs) and inflow control devices (ICDs) presented the opportunity to actively control production and improve flow distribution in each of the laterals. Halliburton specifically designed the FlexRite intelligent completion interface (ICI) system to take advantage of these new, breakthrough technologies.

Halliburton installed the first FlexRite ICI system junction in 2005, which allowed for independent flow control of two laterals. Flow control technology advanced with the advent of the autonomous inflow control device (AICD), allowing for autonomous in-lateral control of production, driving the preferential production of oil versus water and/or gas. In 2008, Halliburton installed the first FlexRite ICI system with AICD technology. The FlexRite ICI system coupled with ICV and AICD technologies allows for an accelerated and improved production curve and independent control of two laterals. This provides operators additional tools to maximize production and minimize detrimental factors, such as gas or water breakthrough. Early evaluation estimated the implementation of ICD and AICD technology increased oil production by 31% and 46%, respectively (Halvorsen et al., 2016). This is in addition to the established production increases achieved through the adoption of multilateral technology in North Sea deepwater.

The proven reliability and merit in controlling two different well branches has driven the implementation of tri-laterals and quad-laterals to commingle flow from the lowest lateral wellbores. This potentially compromises production if a productive wellbore is commingled with a separate wellbore affected by water or gas breakthrough. The FlexRite multibranch inflow control (MIC) system allows selective branch control of more than two laterals. This allowed operators to increase overall reservoir exposure even further, while maintaining the ability to selectively control and monitor each individual lateral. In 2012, Halliburton installed the first FlexRite MIC system junction in a deepwater North Sea application, with more than 140 additional installations completed since then.

decades of construction TAML Level 5 junctions

FlexRite system installations

retrofit or re-entry scenarios

For more than two decades, the FlexRite system portfolio has been utilized to construct TAML Level 5 junctions in North Sea deepwater wells, with more than 300 FlexRite system installations, and with more than 30 in retrofit or re-entry scenarios. The development and continuous improvement of the FlexRite system has allowed operators to maintain, increase, and/ or accelerate production sufficiently to drive increased adoption of multilateral technology.

Data Sheet

The industry’s most robust and most versatile taml level 5 multilateral completion system.

Download Information

FlexRite System

ReFlexRite System

FlexRite MIC System

The Halliburton FlexRite multilateral system is robust, versatile, and configurable for TAML Level 5 pressure sealed junctions