Search

Search

Search

Search

Increased efficiency and higher ROP achieved with less WOB/differential pressure than competitors.

Download PDFUnconventional

Drill lateral section at a high rate of penetration

Haynesville

During drilling operations in a 6-3/4 in. lateral, an operator aimed to reach total depth (TD) while maintaining a high ROP to achieve its financial objectives. Halliburton recommended transitioning from a traditional cylinder cutter to Geometrix® 4D-shaped cutters.

It is common in the Haynesville to experience reduced ROP as lateral drilling distance increases. At the same time, the operator strives to maintain a high ROP to help reduce rig costs.

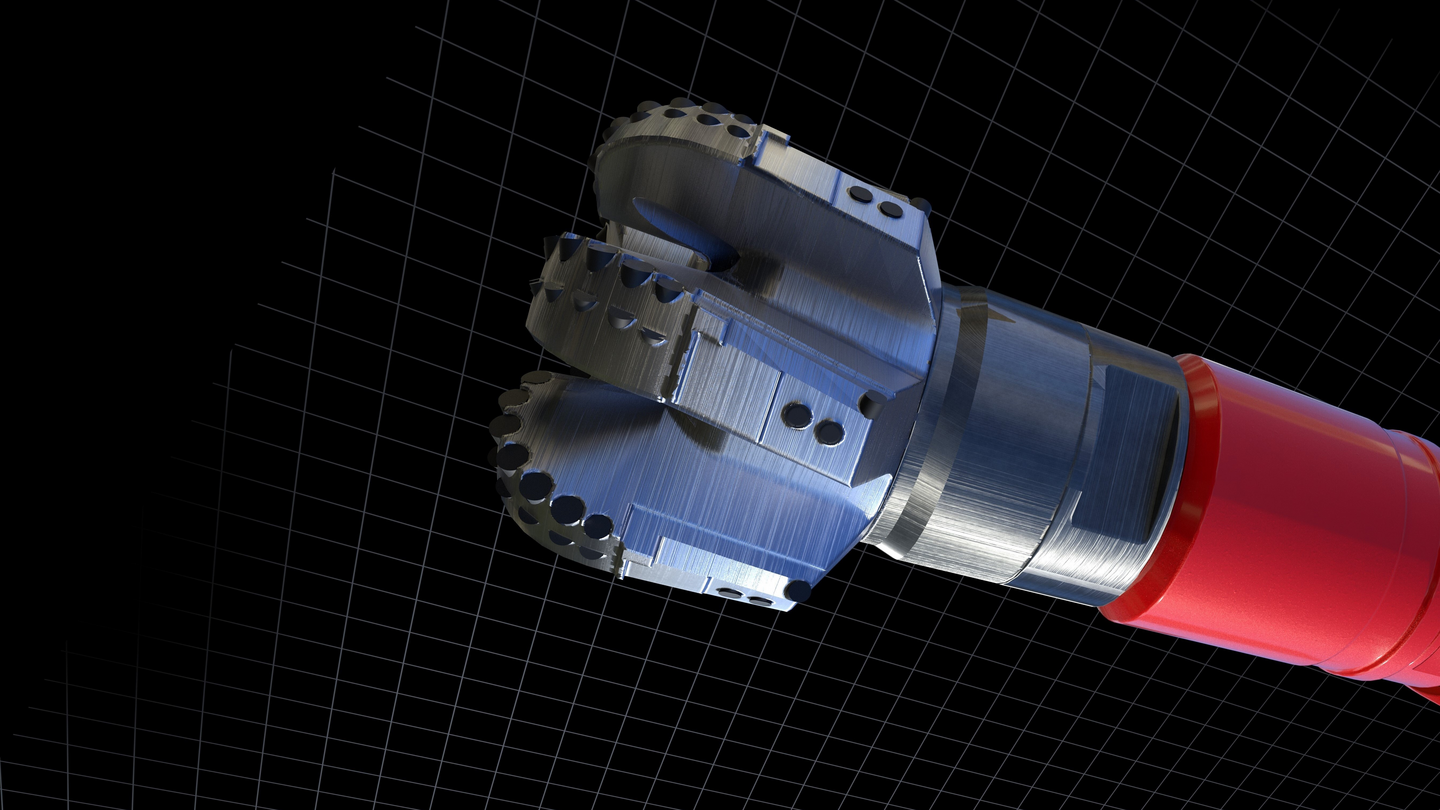

To meet this objective, Halliburton Drill Bits and Services application design evaluation (ADE™) specialist recommended the Geometrix® 4D-shaped line of PDC cutters. These cutters offer unique geometries compared to traditional cylinder cutters to produce more efficient drilling. The various shapes in this offering are customized to different applications to better solve for chip flow, friction, and thermal degradation.

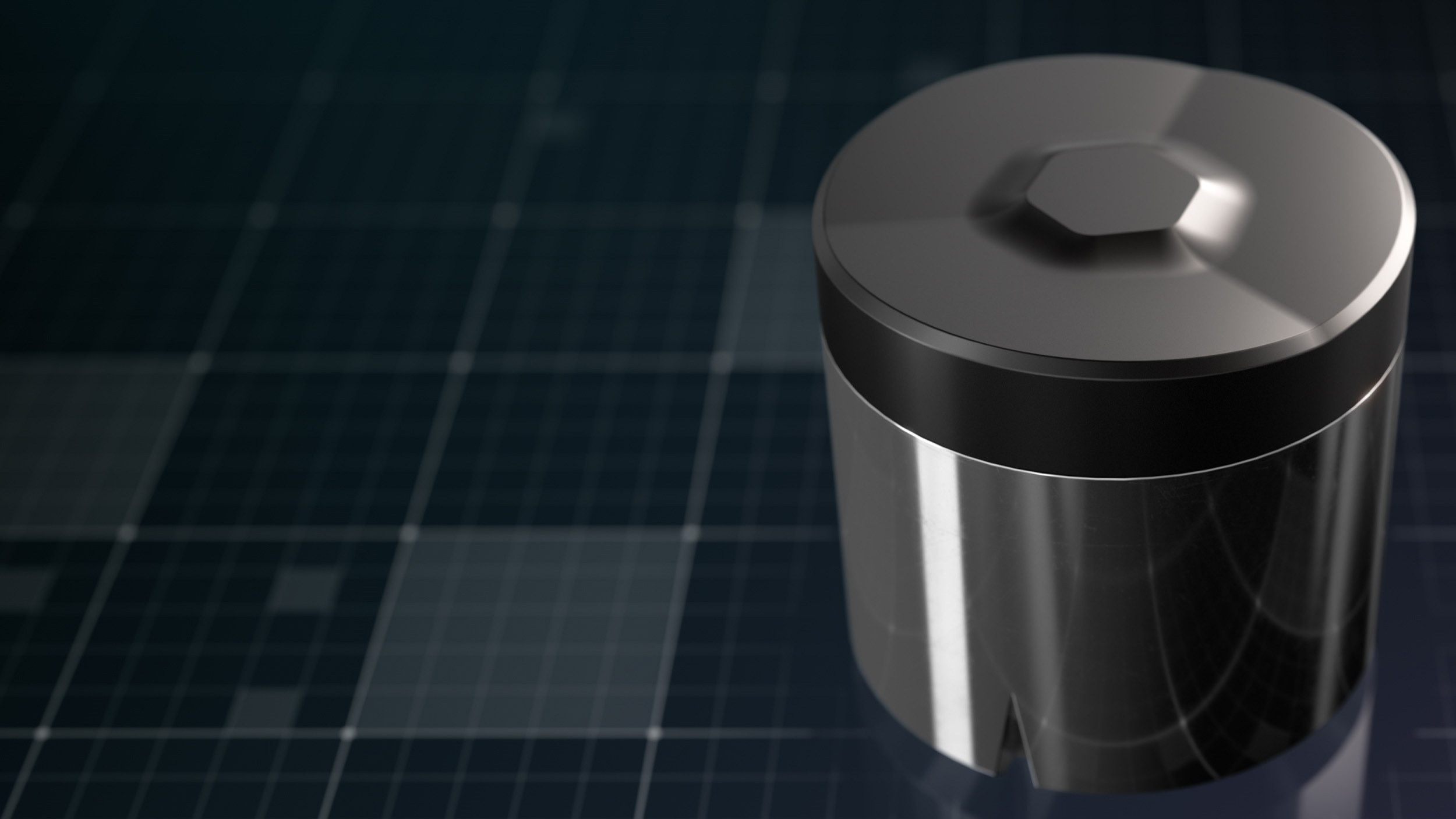

Upon reviewing laboratory data, the Gladius shaped cutter was selected for this application because of the aggressiveness it exhibits in laterals with a 15% improvement in cutting efficiency versus a standard face geometry. The Gladius shaped cutter is equipped with a sharper edge for more efficient shearing, a relieved face to reduce friction, and a centralized chip-breaker to deflect cuttings across the diamond face.

The Gladius cutter exhibited improved efficiency and superior performance during this run, drilling a 1,999 ft. lateral section at an increased ROP and with less WOB/differential pressure than competitors. At a rate of 50.6 ft./hr., the operator reached TD in a shorter time than offset competitors in the field (39.5 drilling hours). Halliburton is working with the operator to run the Gladius shaped cutter during additional operations to continue delivering superior performance with a reliable and trustworthy drill bit that has proven to reduce drilling hours.

Geometrix™ 4D-shaped cutters use different geometries to optimize drilling efficiency and durability.