Search

Search

Search

Search

Solution saves operator significant time and money when compared to problematic offset wells

Download PDFDeep Water

ECD management while drilling

Gulf of Mexico

Offset well data indicated that an operator would encounter a high-pressure subsalt sand between the base of salt at 19,200 ft. (5,852 m.) and 19,700 ft. (6,005 m.) measured depth (MD). A severely depleted sand was known to follow at 19,797 ft. (6,034 m.) MD. The control of equivalent circulating density (ECD) while drilling these sands would be critical to help avoid significant down time.

Records from previous wells showed gas influxes, lost circulation, and stuck pipe incidents within the depth range of 19,200 ft. (5,852 m.) to 19,900 ft. (6,066 m.) MD.

The Baroid technical team recommended a dual approach to ensure the safe and efficient drilling of this section. The plan included the use of BaraECD® high-performance non-aqueous fluid (NAF) system and a WellSET® wellbore strengthening treatment to lower risk of lost circulation.

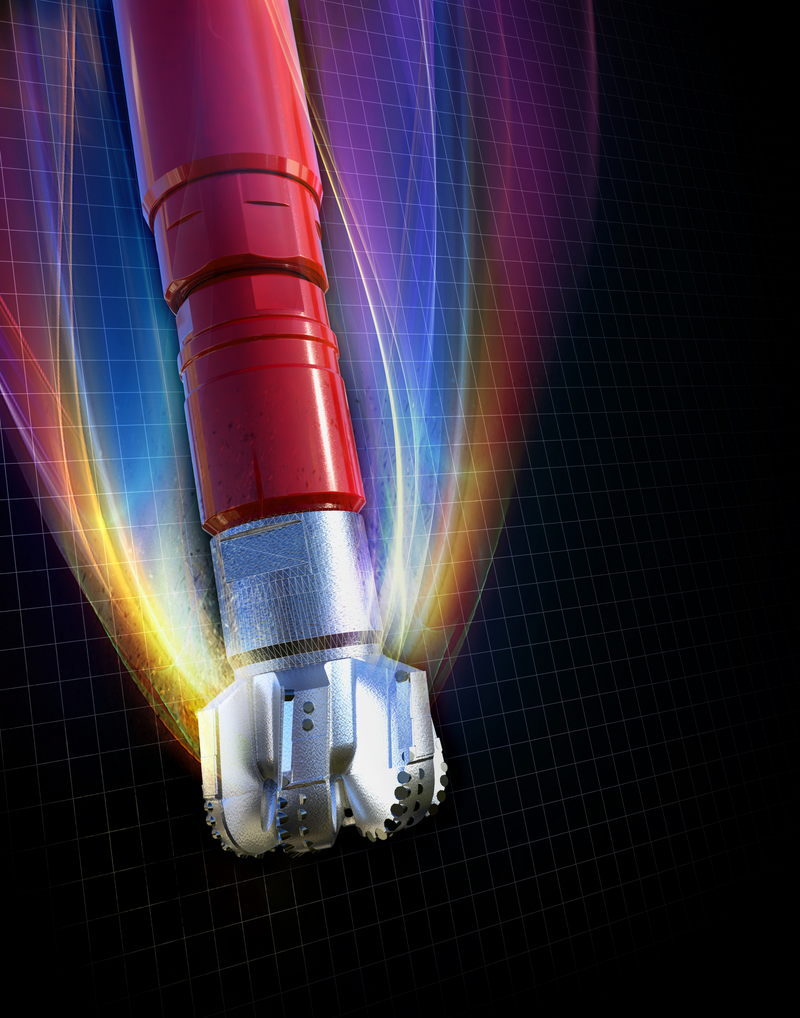

The BaraECD system is designed to improve ECD management in wells with a narrow margin between the pore pressure (PP) and fracture gradient (FG). It incorporates Baroid’s award-winning clay-free technology and includes unique additives that deliver lower ECDs with the maintenance of reliable sag resistance.

The team also applied a WellSET wellbore strengthening treatment, based on the results of an accurate WellSET analysis of pore throat size in the depleted sand. The WellSET software module determined the correct selection and particle size of lost circulation material (LCM) products to create a stress cage specifically for drilling this sand.

Shale shakers were equipped with low-mesh screens to handle large particle sizes from the wellbore strengthening LCM treatment.

days of rig-time savings

USD saved

Non-Productive Time (NPT)

The operator was able to drill from the base of salt at 19,200 ft. (5,852 m.) to total depth (TD) at 19,965 ft. (6,085 m.) MD. Pressure measurements taken while drilling indicated that the pore pressure of the depleted sand was 12.6 lb/gal of equivalent mud weight. Despite this sub-normal pressure, the sand was safely drilled with a 16.1-lb/gal BaraECD fluid system and a pressure differential of 4,039 psi (equivalent to 3.5-lb/gal overbalance).

Without the use of BaraECD NAF and the WellSET wellbore strengthening application, the well likely would have experienced losses and stuck pipe incidents. Since this was the production zone, severe problems could result in costly sidetracks and/or well abandonment.

Daily operation costs on a deepwater drilling rig are estimated at $1 million per day. The high-risk production interval was drilled in two days with zero nonproductive time (NPT). This saved the operator three rig days and approximately $3 million in daily spread costs when compared to problematic offset wells.

Mitigate pressure challenges and simplify completions with our most advanced NAF

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.