Search

Search

Search

Search

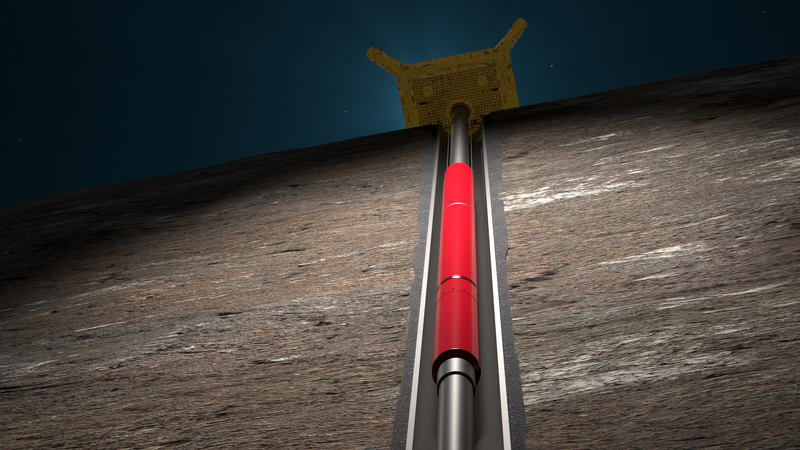

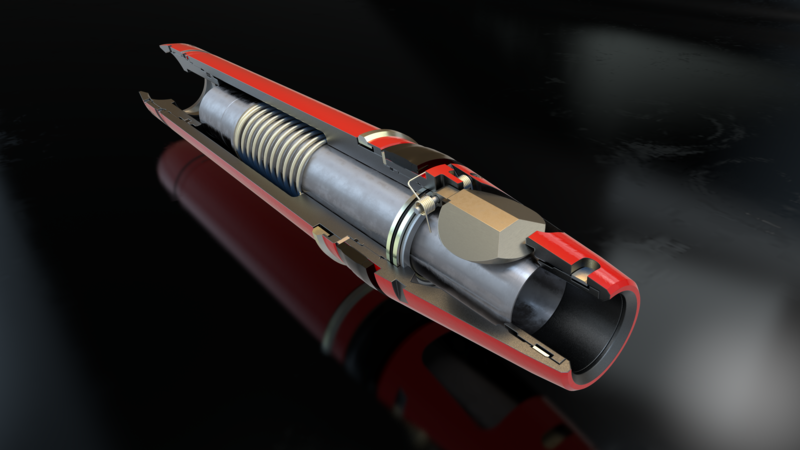

The WI retrievable injection valve is a high-performance, high-flow rate injection valve

Talk to an expertWe achieve high throughput using a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time.

The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below.

The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems.

As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems.

Halliburton tubing-retrievable and wireline-retrievable subsurface safety valves are a field-proven solution for operators.

MC (flapper-type) injection valves are used in injection wells to automatically shut-in the tubing string when injection stops or flow reverses

Halliburton XTR™ CS injection valve for CCUS wells ensures well integrity with contingency insert options and robust design for CO₂ injection