Search

Search

Search

Search

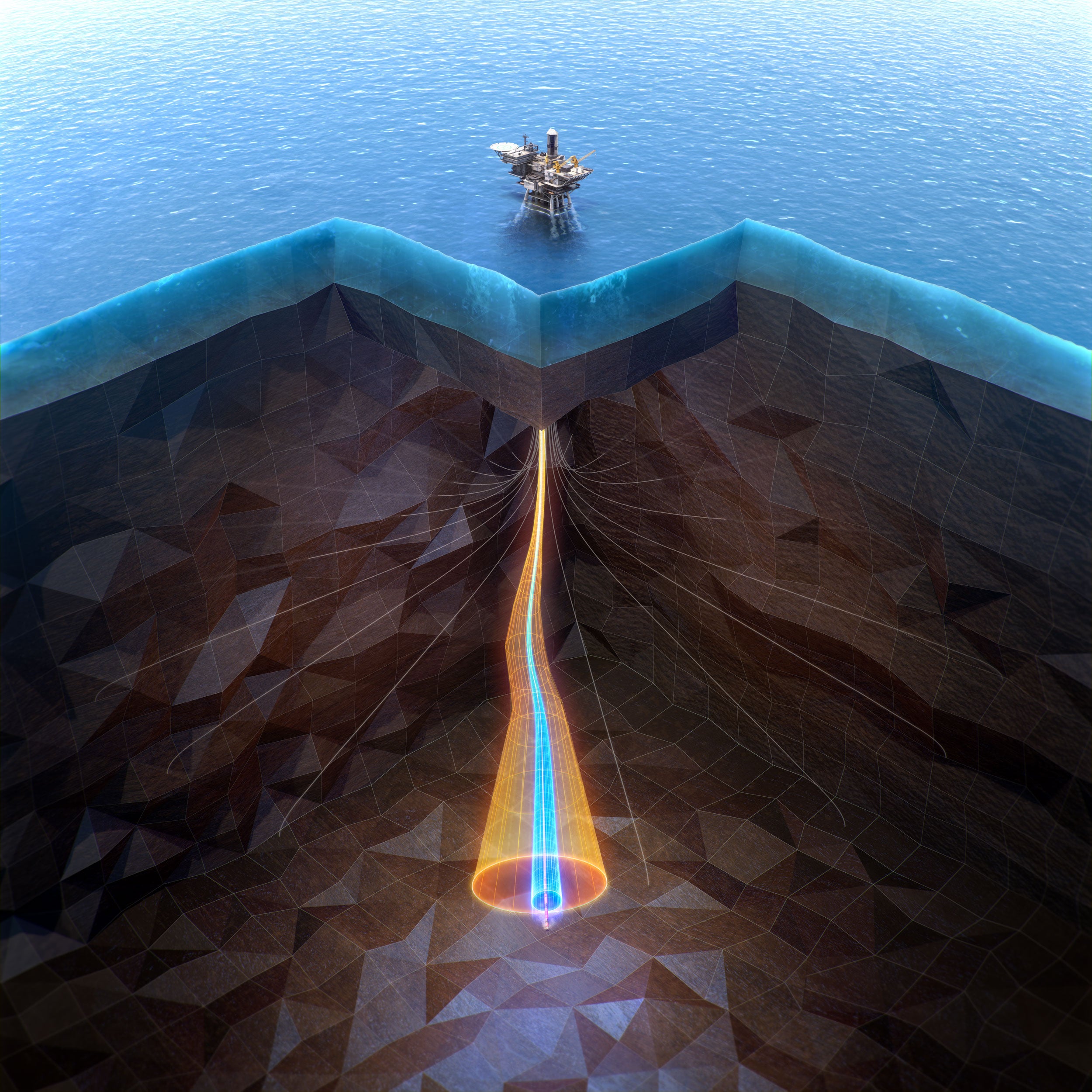

Faster surveys and precise measurements for more accurate well placement

Talk to an expertComplex offshore developments and multi-well pads require enhanced drilling speed and precision. The GyroStar™ gyro-while-drilling service delivers groundbreaking technology that reduces uncertainty while performing surveys twice as fast as the competition. This helps avoid lease lines and mitigate frac hits while enhancing your ability to hit target zones. The sensor package is powered by SPEAR™ solid-state technology and not affected by shock and vibration under normal drilling conditions or by magnetic interference.

Success Story

GyroStar™ gyro-while-drilling service provides precise wellbore guidance and mitigates collision risk.

Read case studyAdvantages