Search

Search

Search

Search

Electro-hydraulic system enables up to 12 zones with only three control lines

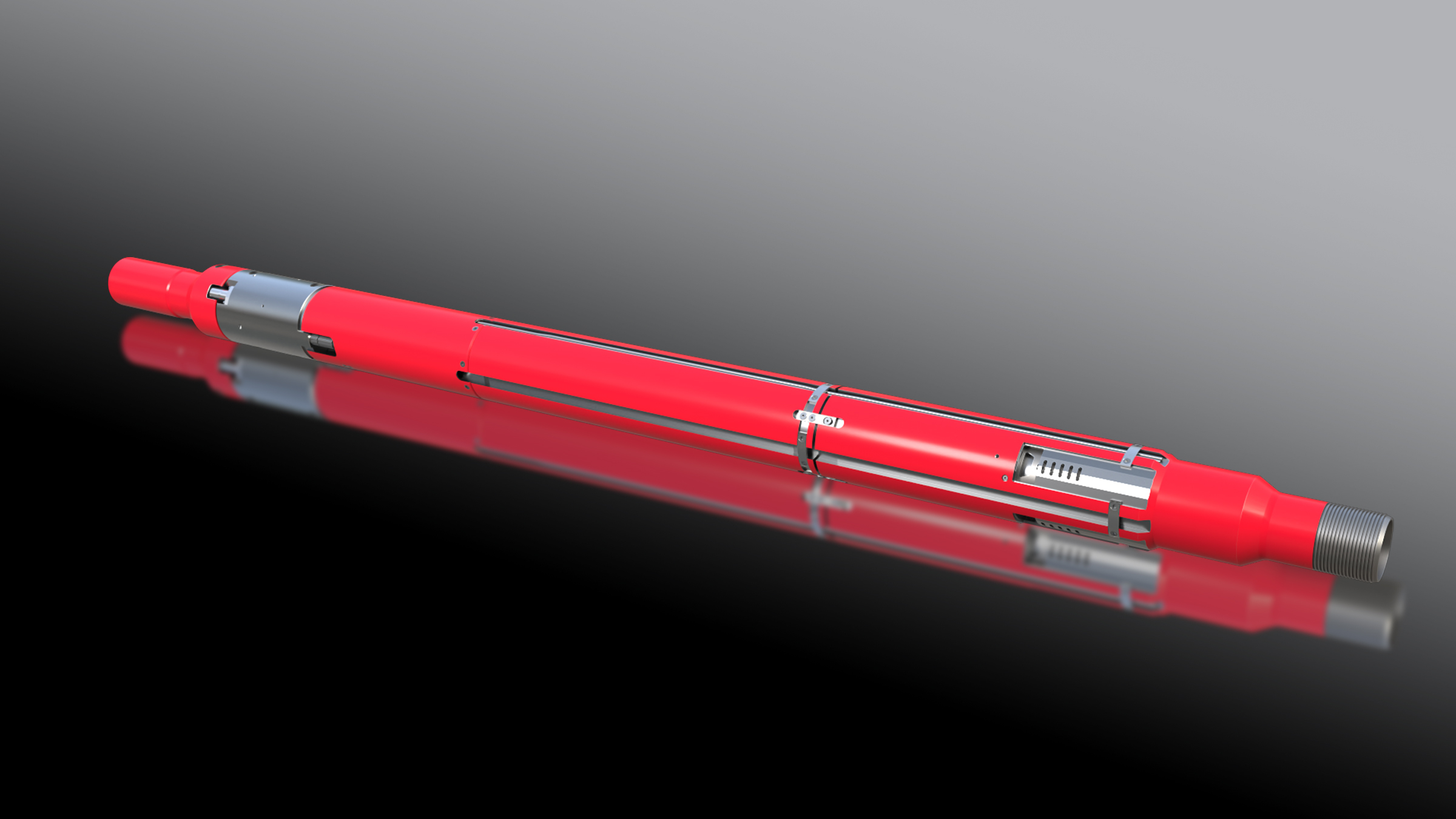

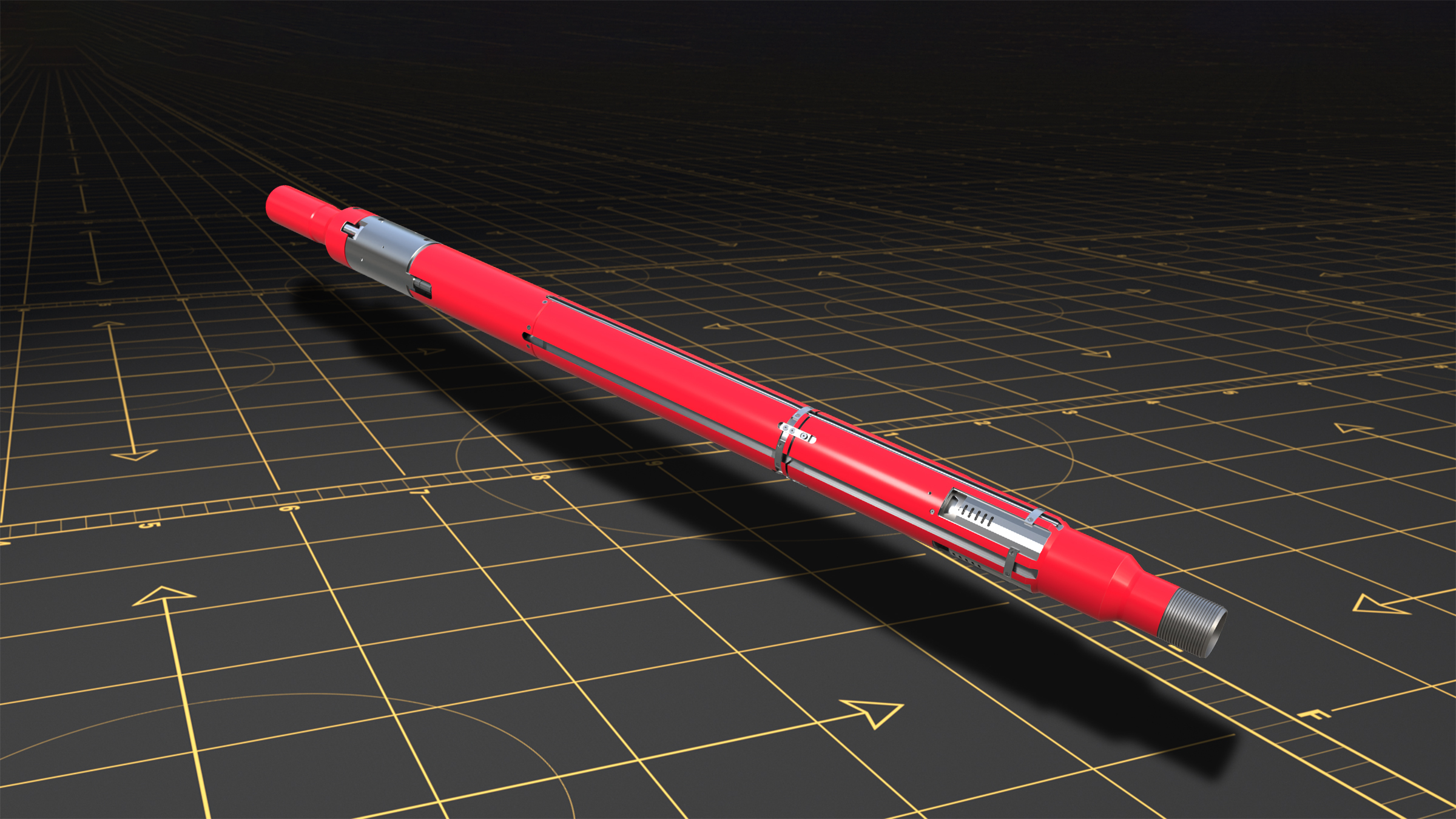

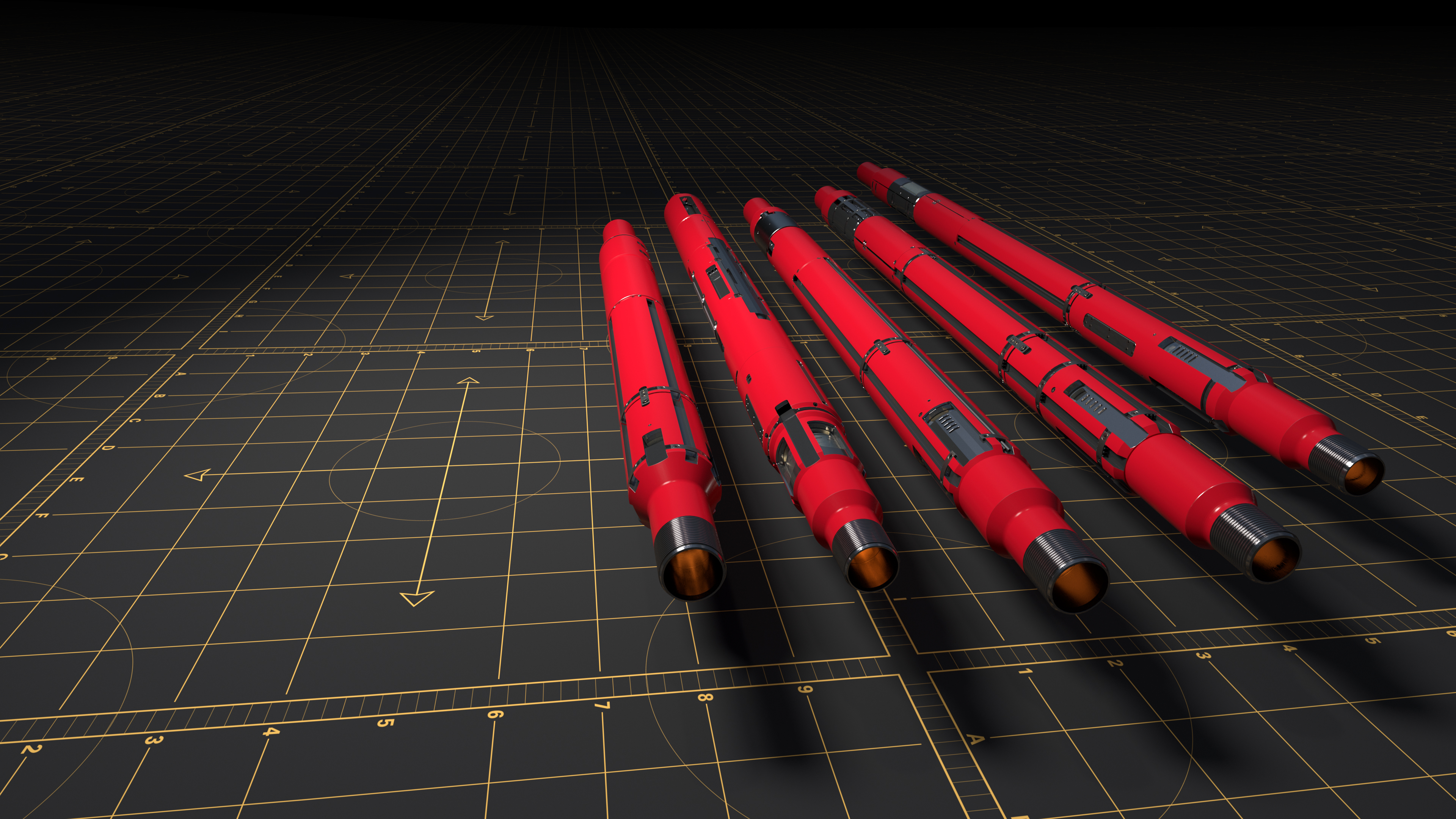

Download PDFThe Halliburton SmartPlex® II downhole control system is an electro-hydraulic multi-drop system that provides simple and reliable zonal control of multiple valves in a single wellbore with a minimum number of control lines. The SmartPlex II downhole control system uses two hydraulic and one electric line from the surface to selectively actuate up to 12 downhole flow-control devices, such as interval control valves (ICVs), from a remote location. This eliminates the need for multiple tubing hanger penetrations and helps reduce operational complexity and risk.

The SmartPlex II downhole control system can be used to control any hydraulic, surface-controlled, flow-control device in the field-proven Halliburton portfolio.

The SmartPlex II downhole control system is applicable for any dry-tree multizone completion that requires more than two valves. Compared to the Direct Hydraulics system, the SmartPlex II system not only helps reduce overall intelligent completion costs, it also decreases complexity because less control lines are necessary.

The SmartPlex II system is ideally suited for long, horizontal, compartmentalized completions (cased or open hole) where selective control of each interval is desired. Typically, this can be advantageous for high-rate multizone water injection, selective stimulation control in tight gas applications, or in combination with a choking ICV for drawdown optimization in production applications.

Halliburton intelligent flow control systems provide a method to integrate manual or automated surface control systems with downhole SmartWell® completion equipment.