Search

Search

Search

Search

Locations with increasingly strict environmental regulations require unique and integrated waste management solutions. Zero discharge projects can incur significant expenses in waste transportation and final treatment and disposal of cuttings. Our BaraCRI® Cuttings Reinjection Service is customized for every project to allow safe, efficient cuttings disposal in annular injection or disposal wells.

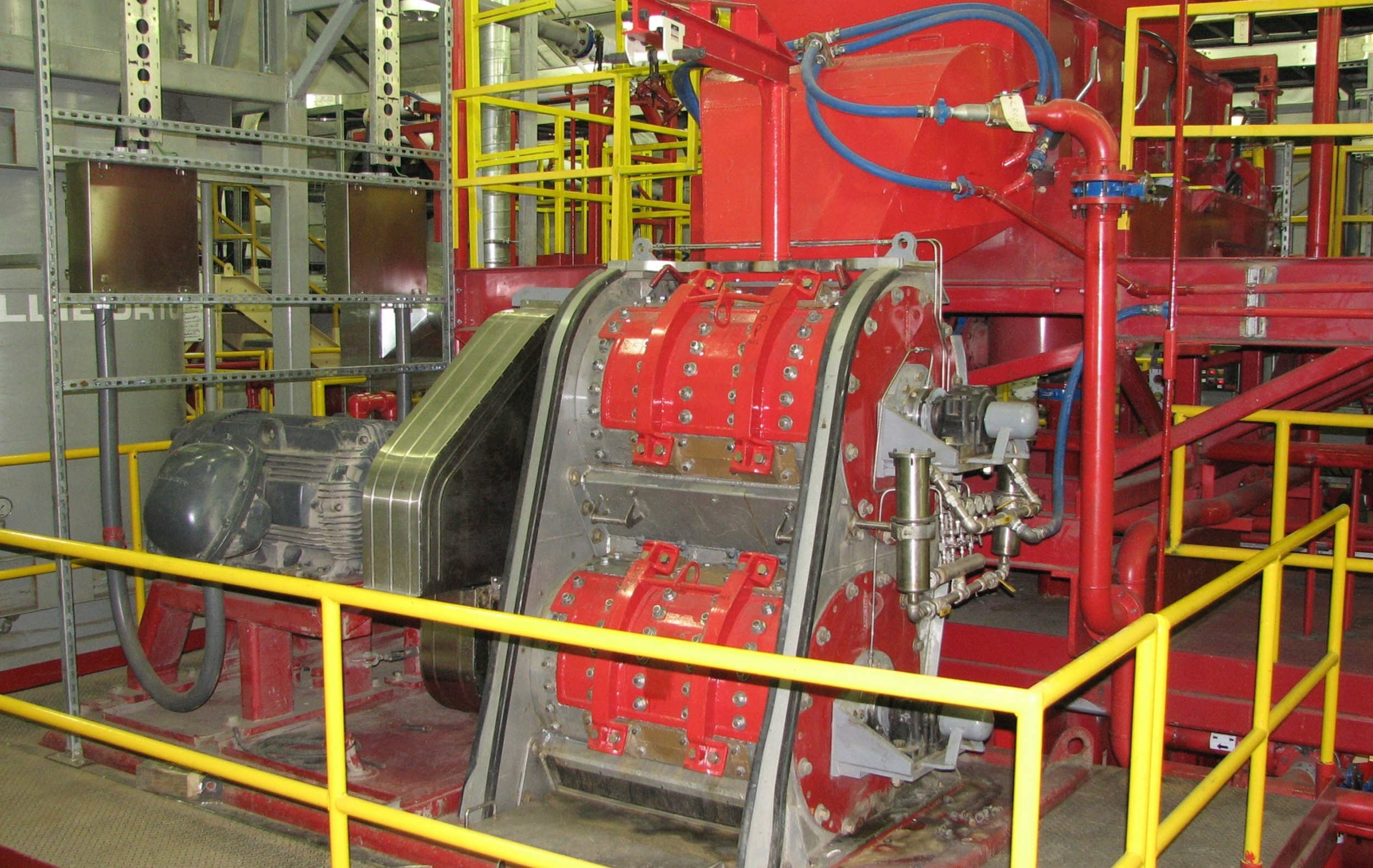

We combine two-stage hammermill processing with advanced slurry rheology design to optimize downhole injection of cuttings. Feasibility analyses and rigorous planning help us engineer cuttings reinjection systems that meet all operational and environmental requirements, so you can dispose of cuttings without expensive treatment options or long-distance transportation to disposal facilities.

Every BaraCRI℠ project, whether offshore or on land, incorporates real-time monitoring and support. With industry-leading grinding capacity, we can help you reduce NPT with real-time processing of drill cuttings. We also help you execute and verify the solution, so you can consistently meet zero discharge requirements and enhance your environmental leadership position.

Comprehensive and efficient technology solutions for optimal fluid recovery and minimal environmental impact.