Search

Search

Search

Search

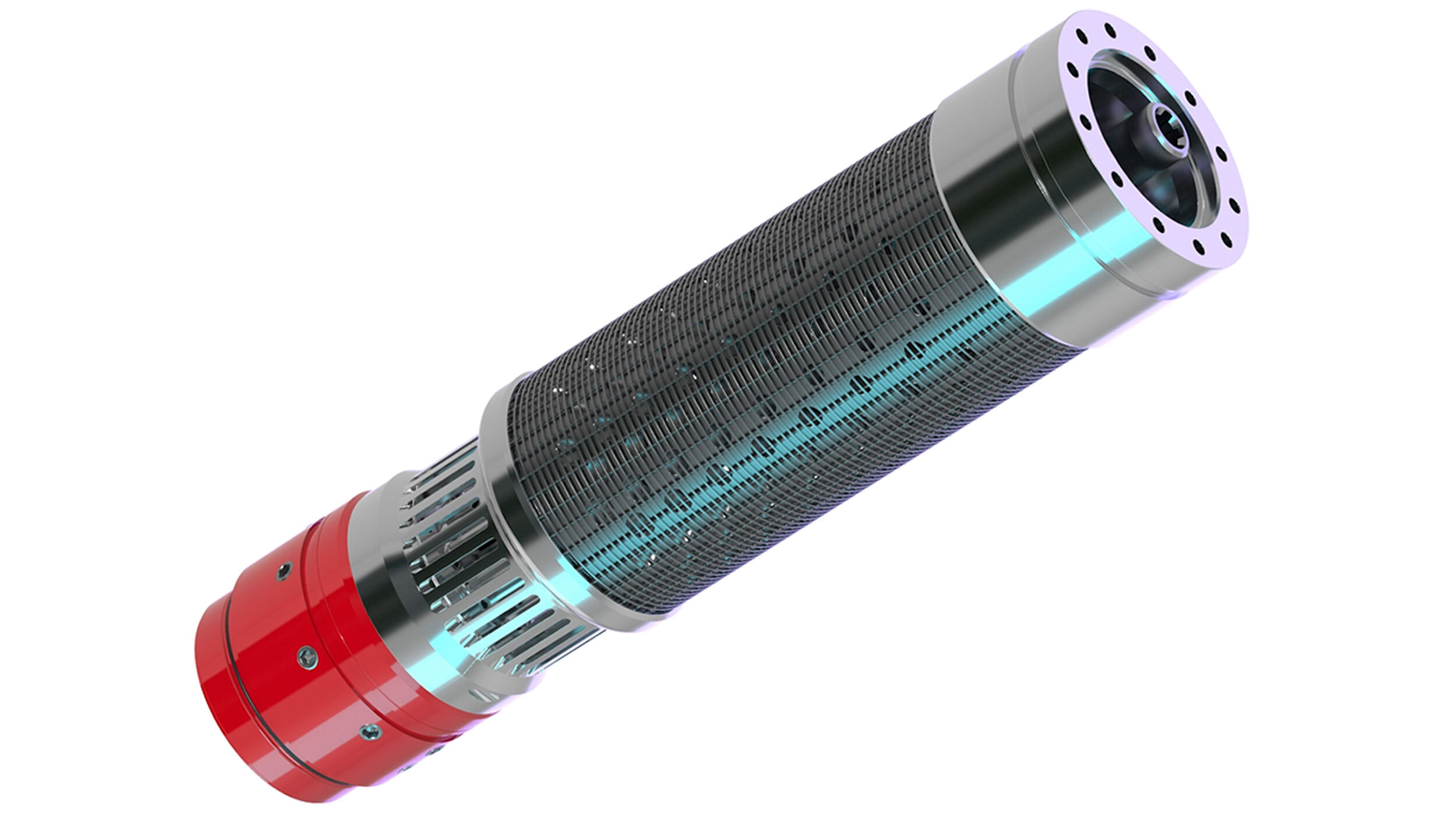

Innovative, modular design seamlessly adapts to a diverse array of pumps and seals, delivering unparalleled solids protection

talk to an expertEasily interchangeable, modular pump intake design with screened housing protects against small-sized solids and debris. Optimized inflow geometry reduces pressure drop for increased energy savings and further mitigates the development of scale and casing erosion around the pump inlet.

The GeoESP Intake system, designed for use with electric submersible pumps (ESP), leverages Halliburton Completion Tools’ sand screen technology. It offers tandem connections to boost intake rates while minimizing pressure drop at the pump inlet.

Real-time decision-making allows operators to choose between a standard intake and GeoESP Intake based on pull information.

Effortless maintenance ensures minimal downtime by allowing easy flushing from above through the riser. This innovative solution enhances well construction optimization for geothermal applications.

Designed for use with ESPs, the GeoESP Intake operates with significantly lower power consumption, resulting in cost savings and enhanced operational flexibility.

In high-flow geothermal applications (>50 K BPD - 92 L/s), the intake can reduce pressure drops across the inlet by over 30%. This reduction translates to substantial cost savings and contributes to a reduced carbon footprint.

The intake is highly versatile and can be customized to accommodate multiple equipment flanges. This adaptability allows seamless integration with various pumps and seals, addressing diverse production challenges. Overall, the GeoESP Intake represents an efficient and eco-friendly solution for any geothermal application.

designed specifically for geothermal applications

Pressure drops across the inlet in some cases

Larger inflow rate

bfpd (185 l/s) inflow per section

Tiger Shark® pumps adapt to changing well production, improving operating range and run life. Tiger Shark II pumps are designed for maximum flexibility in conventional, unconventional, and gassy wells, while Tiger Shark III addresses extremely abrasive deep wells with high discharge pressure.

DuraHard coatings protect against friction, abrasive, and corrosive conditions, providing longer pump run life.