Search

Search

Search

Search

Halliburton reservoir testing and analysis illuminates the subsurface, giving operators a clear view into the reservoir.

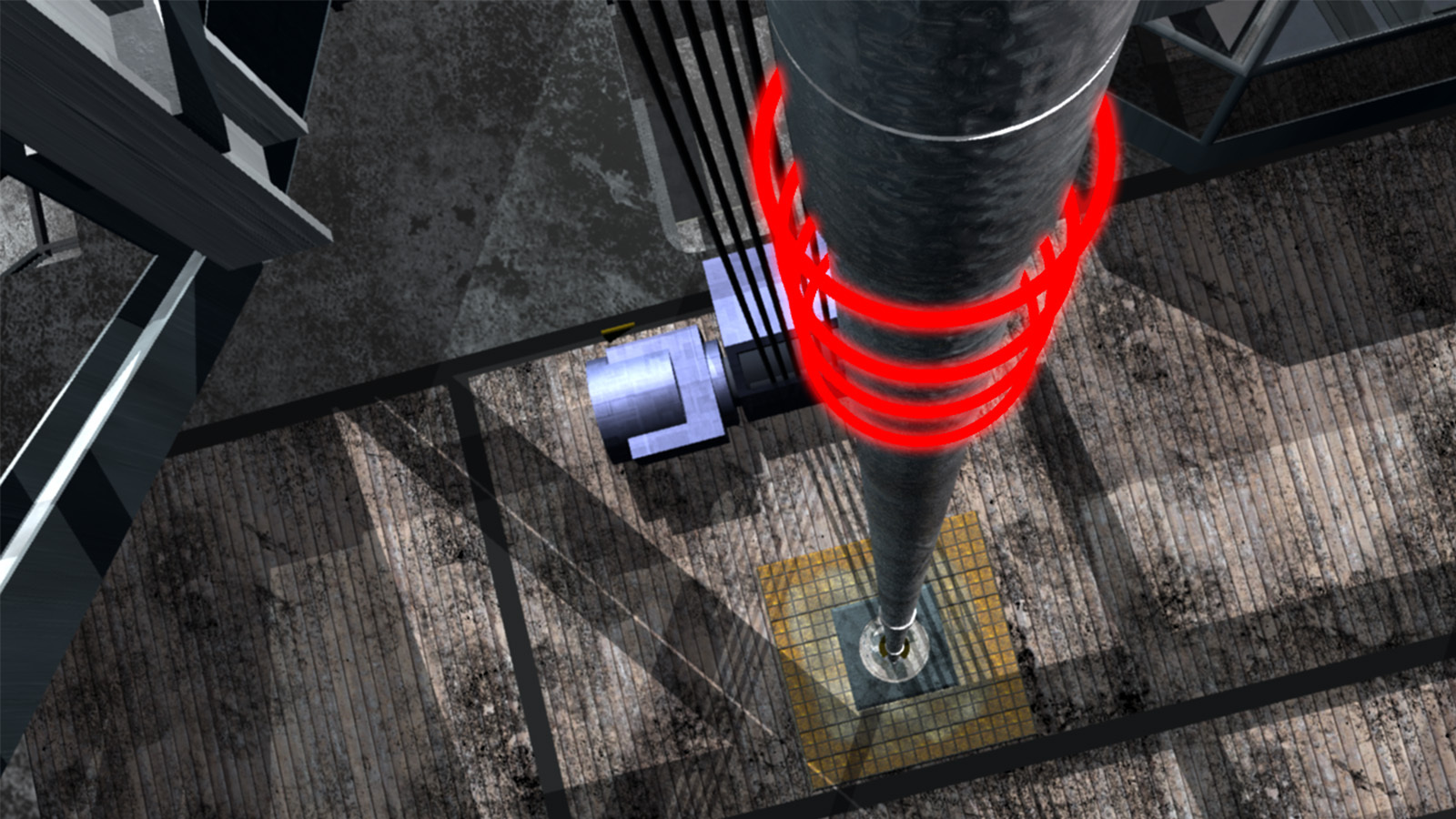

talk to an expertTesting is vital to reservoir understanding and requires testing tools and systems that provide dynamic control and analysis in real time. Halliburton’s extended well testing portfolio gathers critical data operators need most, from downhole temperature data to reservoir samples to subsea safety systems. This data provides a full view into reservoir permeability, skin, initial pressure, and more, enabling better decision-making.

Real-time well testing solutions for measuring and analyzing well-test data.

Explore

Halliburton surface well testing (SWT) tools and solutions compile full and reliable data, enabling better reservoir evaluations and appraisals.

Explore

Deepwater safety solutions for exploration, appraisal, completion, and intervention.

Explore