Search

Search

Search

Search

Increase ROP, enhance well placement, and improve wellbore stability and hole quality with innovative formation evaluation solutions

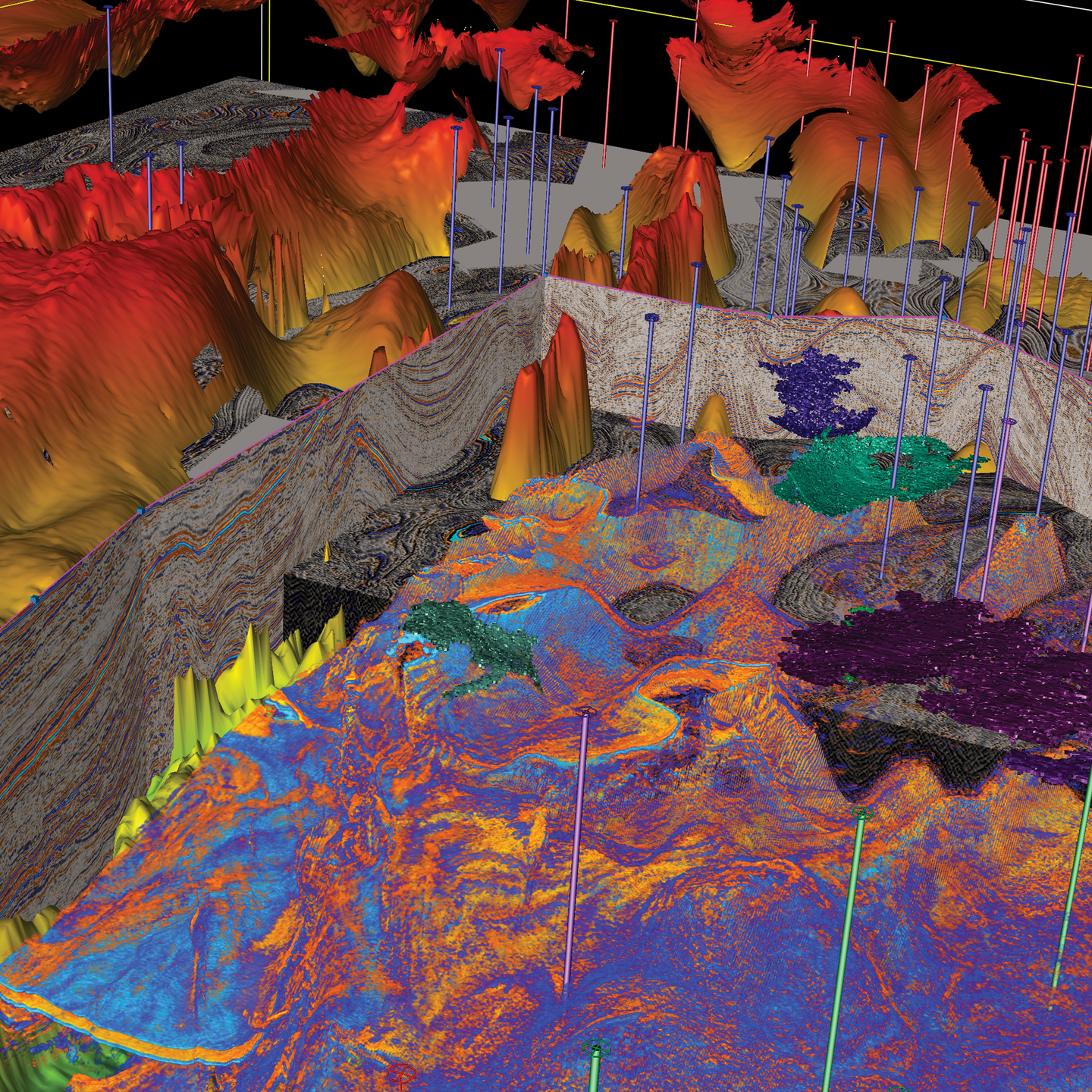

Talk to an ExpertFully characterize and accurately assess your reservoir’s lifetime production potential with Halliburton’s formation evaluation solutions. We help build a comprehensive understanding of the subsurface using cutting-edge technology, including static and dynamic reservoir digital twins, high resolution imaging, and real-time data integrated with geoscience software.

Unlock increased production and improved efficiencies for the life of the well with solutions tailored to meet the requirements of your well development and completions strategies.

As hydrocarbon exploration pushes new boundaries in unconventional source rock and deepwater extraction, high-quality data is required to create models for production potential. Halliburton collects high-resolution data from logging while drilling, wireline runs, and other sources with sensors that measure pressure, temperature, and other elements in-situ and in real-time.

We integrate collected data seamlessly with geoscience software and use pioneering analytics and algorithms to produce optimal geological models that incorporate petrophysics, geology, geomechanics, and geophysics for more precise prediction of subsurface conditions. Gain a better understanding of your reservoir and optimize the lifetime performance with Halliburton’s innovative tools and expertise.

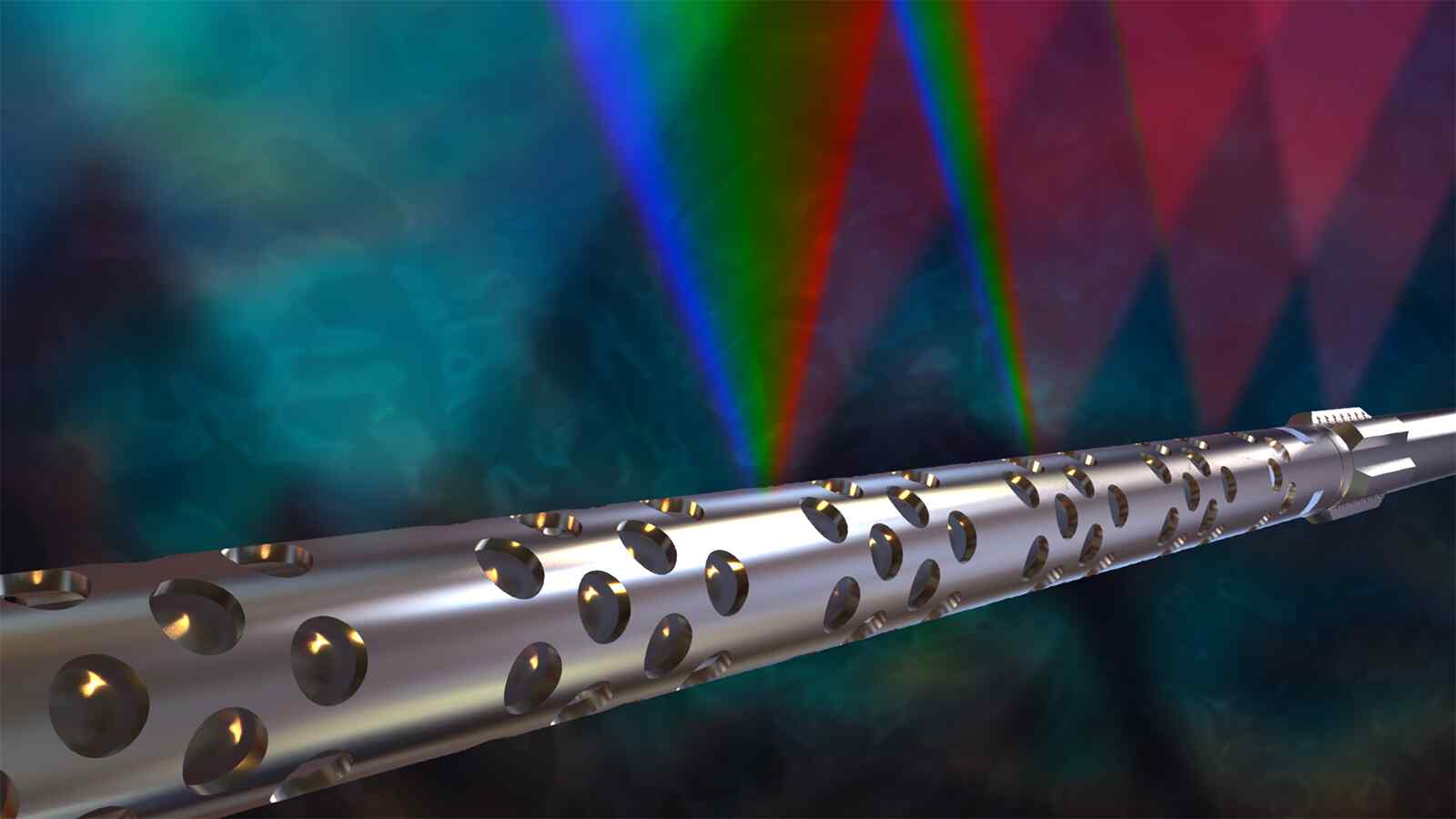

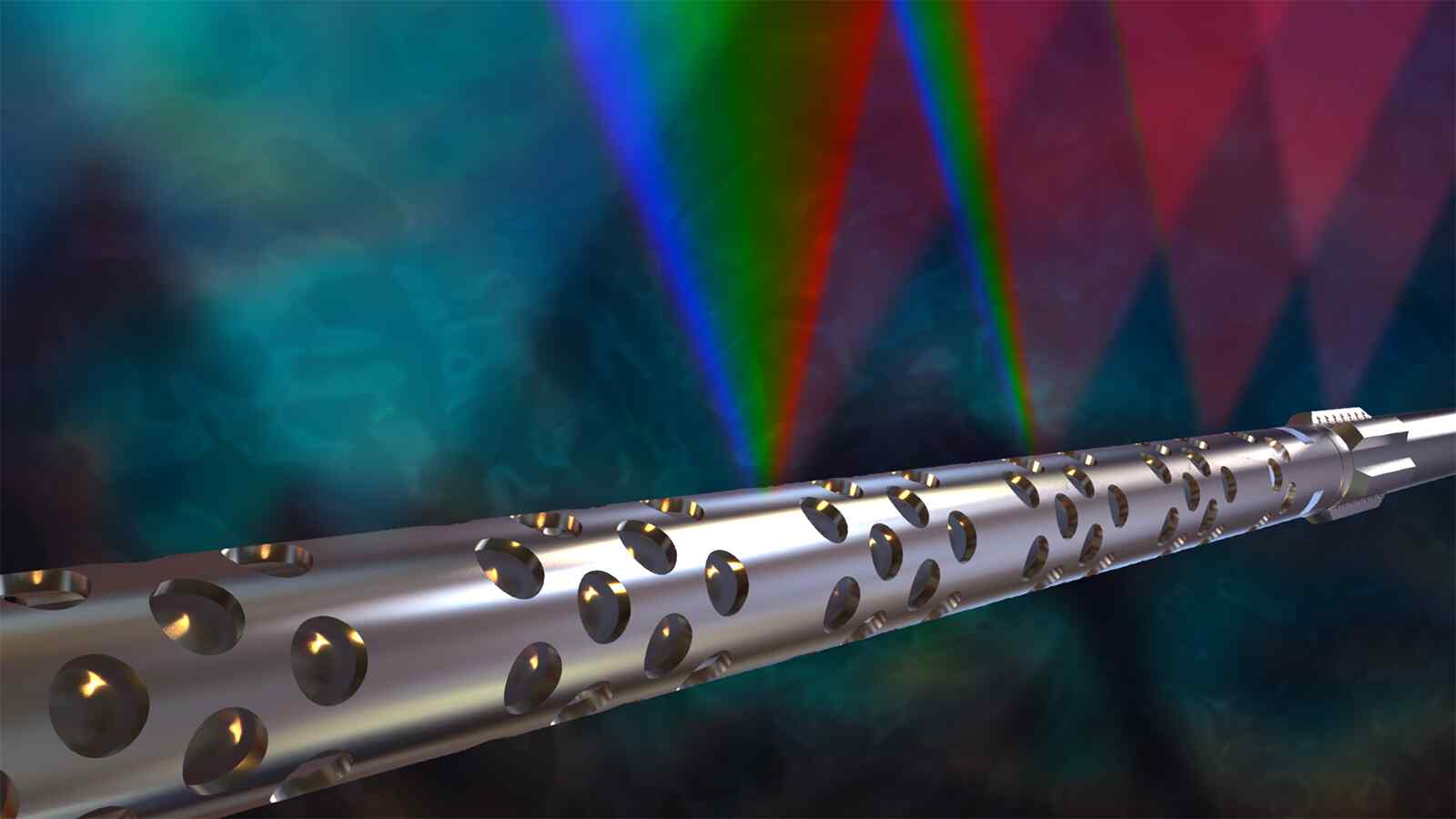

iCruise X intelligent rotary steerable system

By automating your drilling process, you can maximize asset value through reduced well time, fewer rig site personnel, and lower costs per BOE while achieving predictable, reliable results in the most challenging conditions including extreme temperatures, variable quality mud chemistry, and when a high dogleg severity is needed.

explore iCruise X

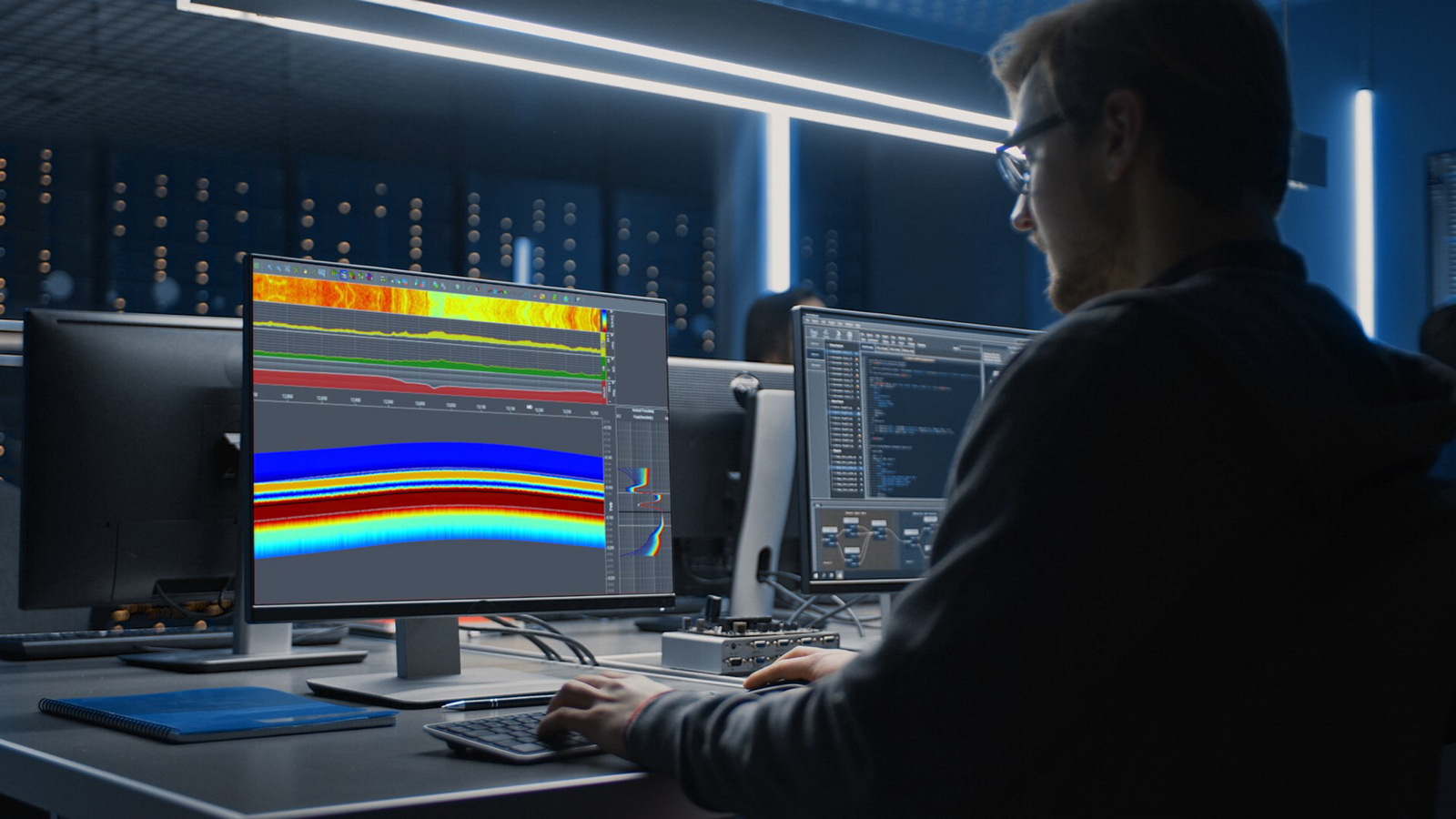

Fully understanding your formation requires making sense of subsurface data. With the help of our team of formation evaluation experts, we help you make the most of your data and the technology. From deploying these applications in private, public, or hybrid cloud environments to integrations with existing technology, we work with you to ensure you maximize your investments, improve decision making, and achieve enhanced reservoir understanding for optimal production. Halliburton collaborates with customers to provide subsurface understanding and risk reduction.

Reservoir Xaminer™ grants high-quality formation evaluation data in real-time for improved data quality, optimized rig time, and a higher asset value.

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.

Combines innovative technology and tightly integrated, end-to-end suite of cross-domain workflows to increase subsurface understanding, reduce uncertainty around today’s most complex reservoirs and tackle future energy challenges.

Fully digital and web-enabled to monitor and control drilling and logging operations from anywhere.

Direct formation pressure measurements on-demand.

HalVue™ Real-Time Viewer gives you a consistent view of data across operations as it comes in from the rig to help maximize asset value.

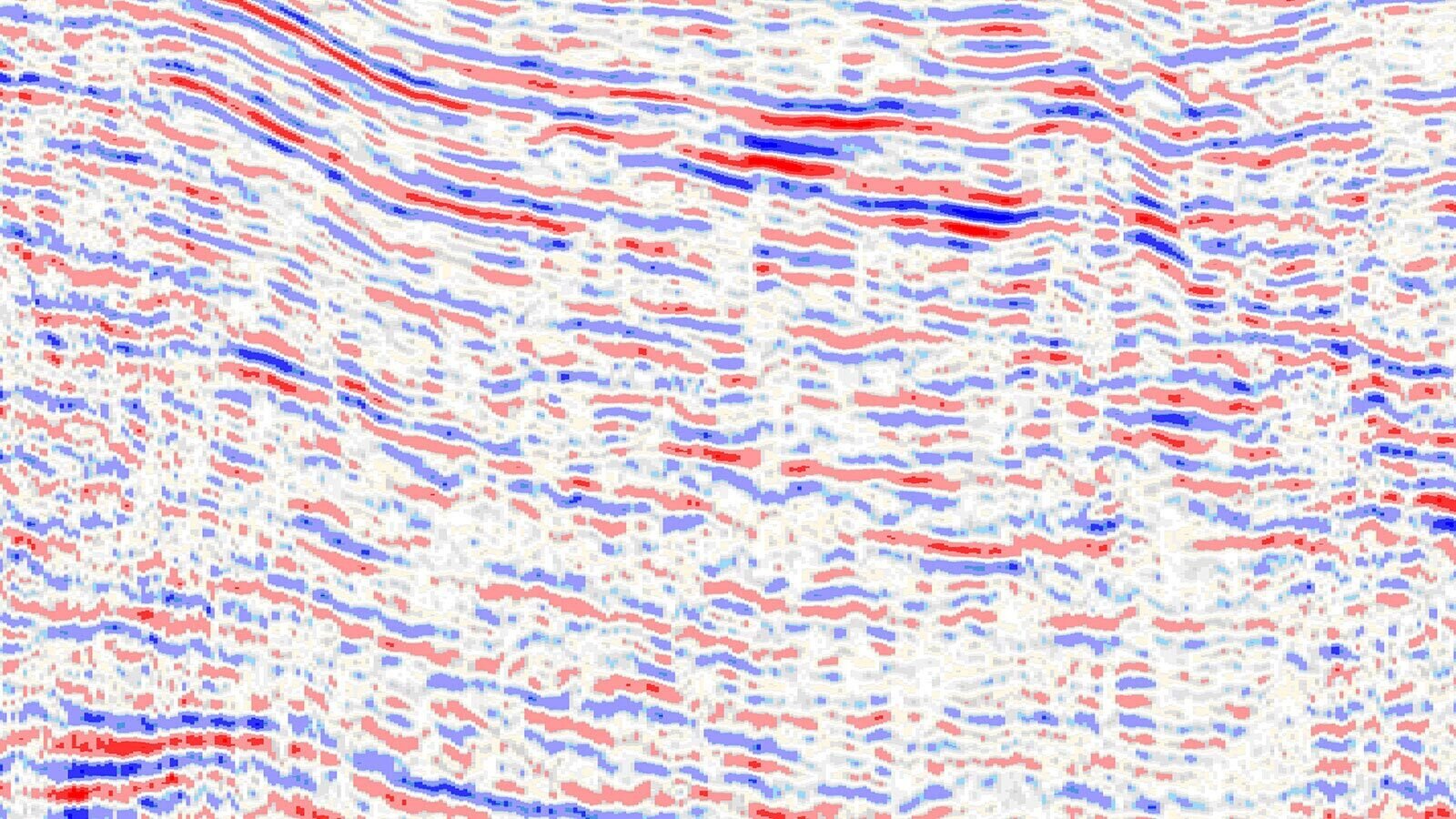

The Halliburton StrataXaminer™ Imaging Service provides more accurate well data to better evaluate production potential and increase return on investment.

Acoustic analysis tools that pinpoint costly wellbore leaks by analyzing sound waves that describe flow patterns in the formation and casing.

Halliburton delivers real-time information from your well, enabling better and faster drilling and geological decisions.

Explore

Expand geological and petrophysical knowledge with Halliburton LithoFact® Advanced Cuttings Analysis Service.

GasFact gas analysis service from Halliburton Sperry Drilling is a surface data logging service that combines the capabilities of the constant volume and temperature gas extraction

Gather real-time, high-quality data while drilling for improved subsurface insight, increased ROP, and enhanced wellbore stability.

Explore

Halliburton's wireline openhole logging tools are easily deployed to acquire critical subsurface data, ensuring reliable insights for operators in the industry.

Explore

Reservoir Xaminer™ grants high-quality formation evaluation data in real-time for improved data quality, optimized rig time, and a higher asset value.

The Halliburton StrataXaminer™ Imaging Service provides more accurate well data to better evaluate production potential and increase return on investment.

Halliburton cased hole logging tools give operators the measurements to optimize reservoir performance and evaluate well integrity.

Explore

Acoustic analysis tools that pinpoint costly wellbore leaks by analyzing sound waves that describe flow patterns in the formation and casing.

Monitor reservoirs to increase production, improve recovery, and find bypassed pay.

Halliburton provides full service slickline capability from basic completion intervention applications to advanced services.

Explore

With the RELAY digital slickline system, you can improve well intervention efficiency, reduce uncertainty, and minimize environmental impact.

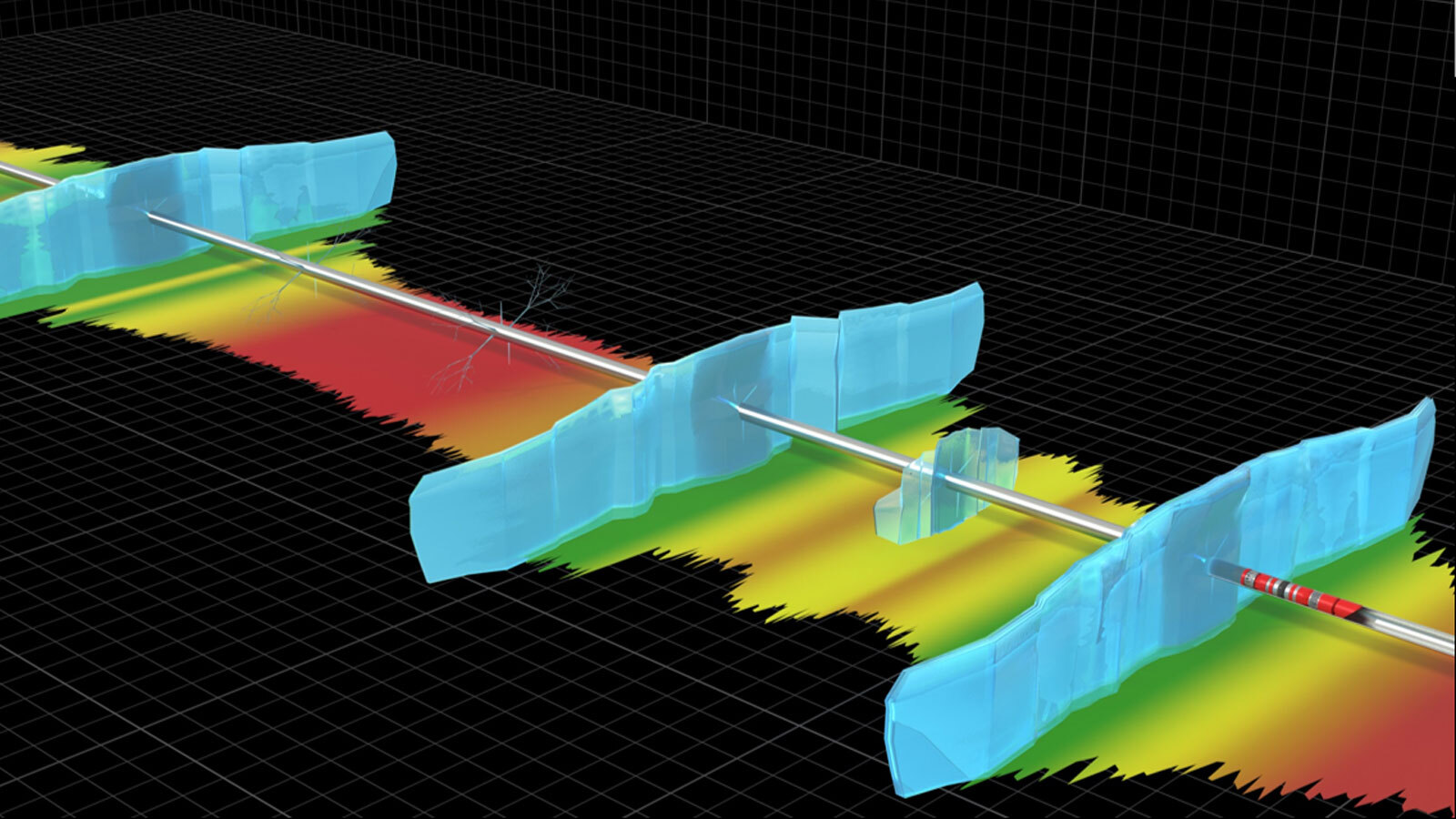

Halliburton advanced seismic technology delivers higher-resolution imaging, from the surface and downhole.

Explore

The Halliburton FiberVSP™ service offers a quick, cost-effective, and low-risk solution for acquiring high-spatial-resolution VSP data.

Odassea™ service integrates hardware and digital systems to strengthen cyber capabilities in subsea reservoir monitoring and production optimization.