Search

Search

Search

Search

Halliburton designs, delivers, and validates sustainable barriers tailored to minimize risk and maximize production.

Talk to an expertToday, Halliburton leads the way with a full range of state-of-the-art cementing solutions and casing equipment engineered to effectively place cement, improve zonal isolation, prevent fluid loss, and manage sustained casing pressure. From reliable equipment and customized chemistry, to cutting-edge modeling and automation, Halliburton delivers cementing solutions for improved performance and integrity throughout the life of the well.

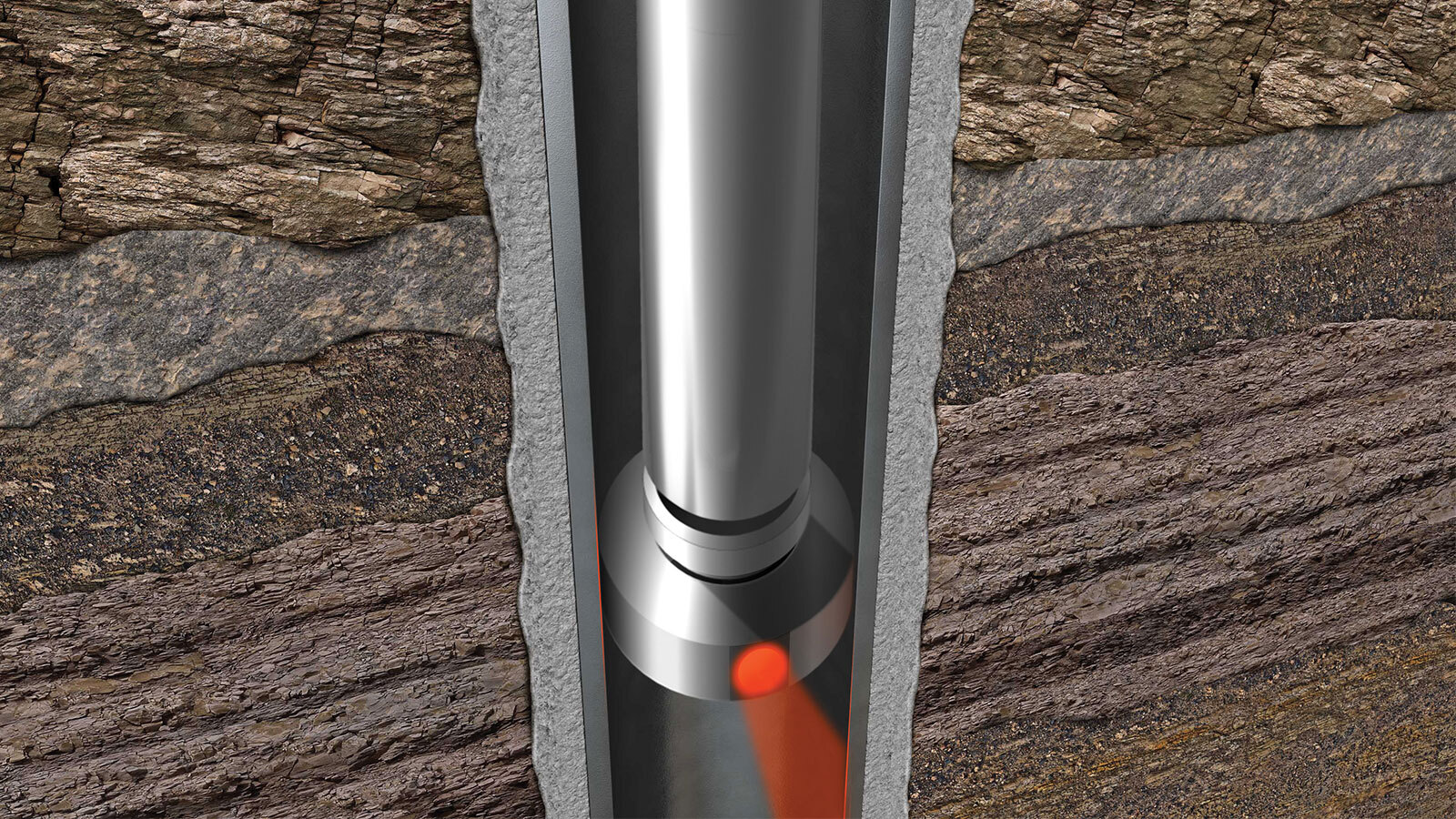

Secure the primary cement job amid extreme conditions and increase the return of uncontaminated mud to the surface.

Explore

Fit-for-purpose pumping and mixing equipment for both land and offshore, recognized worldwide for safety, effectiveness, and reliability.

Explore

Ensure wellbore-integrity and sound technical decision-making throughout the life of the well.

Explore

Meet the unique pressure, temperature, and property demands of each well.

Explore

Achieve quick, accurate information on cement bond, casing evaluation, and well integrity.

Explore

Halliburton casing solutions help run and land casing to depth, ensure proper centralization, and achieve long-term zonal isolation.

Explore