Search

Search

Search

Search

With industry-leading expertise and a customized approach, our teams are prepared for any resource play, anywhere in the world. Using rigorous practices and advanced digital technologies, we engineer solutions that boost overall performance while improving safety.

Engineered fluid solutions customized to maximize wellbore value.

02:08

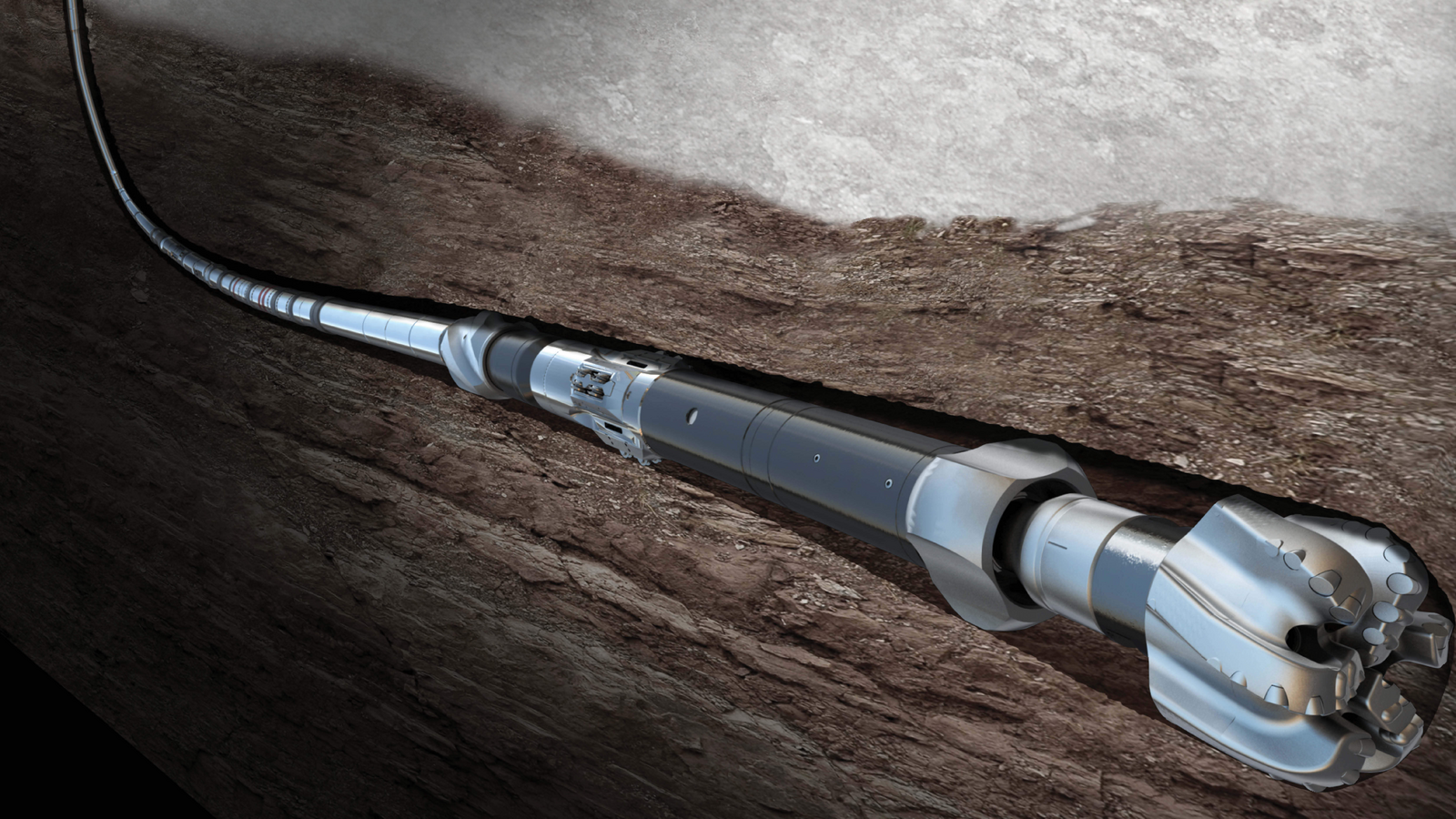

Custom drilling solutions for increased performance, more accurate planning and monitoring, and greater risk mitigation and safety.

Explore

Expansive portfolio of engineered high-performance water-based fluids and additives that can be customized to meet your specific challenges

Collaborative and process-driven solutions to optimize fluid performance, maximize solids removal, and minimize cost.

Explore

Comprehensive and efficient technology solutions for optimal fluid recovery and minimal environmental impact.

Explore

Halliburton slops treatment helps operators achieve higher profit margins from process-driven execution, advanced technologies, and extensive experience.

Specialized drill-in fluids for every reservoir that improve well productivity and reduce formation damage.

Explore

Halliburton completion fluids optimally prepare, repair, clean out, and complete the wellbore to maximize production.

Explore

BaraKlean® cleaners promote wellbore cleanliness to lower costs and boost production.

Explore

Proven corrosion-control treatments that mitigate the corrosive qualities of drilling, completion fluids, and other downhole factors.

Explore

Baroid’s breaker systems remove filter cake to improve productivity or injectivity of treated wells.

Explore

Customized filtration solutions maximize filtration and ensure environmental compliance for fluid discharge.

Explore

Reduce or eliminate differential pressure across the packer with Baroid’s packer fluids, extending packer life and reliability.

Explore